Examples

A) #4-40 x 0.5 HWH square drive drill point

B) 1/4-20 x 5/8 Phillips Truss Head driller

C) M3-0.50 x 10 Pan Head type AB

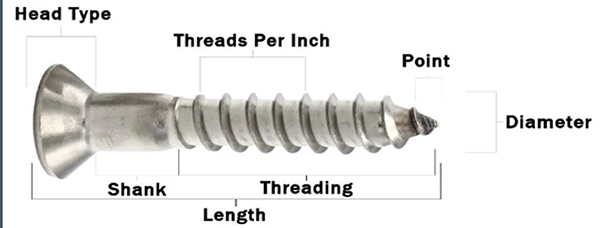

The first number in the callout indicates the major diameter. Unified threads (in inches) express diameter as a fixed number #0 through #10, like example A listed above. When threads get to ¼” it gets confusing. For instance: a #14 is 0.248” – 0.254” but a 1/4” is 0.237” – 0.246” like example B. Then a #17 is 0.273” – 0.280”. After that then they go to the nearest fractional dimension. Metric threads express diameter with M followed by the diameter in millimeters, like example C.

The second number in the callout indicates the distance between threads. It can be expressed as the number of threads per unit or as the distance between identical threads (the pitch). Unified threads measure threads per inch. In example A, the screw has 40 threads per inch. Metric threads measure millimeters per thread. In example C, the screw has threads every 0.50 millimeters.

The length is the number that follows the x. Unified threads measure the length in inches, expressed as a decimal or a fraction interchangeably. In example A, the thread length of #4-40 x 0.5 is 0.5 or 1/2 an inch. Metric threads give the length in millimeters, example C, is 10 millimeters long.

Confused? That’s ok. Your supplier can assist you with ordering the right choice for the right application.

Source: ST Fastening Systems