The Big Steel Rack is used to hold material in wait for shipment.

Storage Solutions

Big Steel Rack in Jackson, Michigan, specializes in custom storage racks for the manufacturing industry. Their original “Big Steel Rack” is a sheet rack that holds specialized 3″-thick metal pallets stacked vertically with 4″ spacing between the pallets. With traditional wooden pallet storage solutions, said Brandon Bartel with Big Steel Rack, “you lose that much more density in your storage.” Bartel has plenty of ideas and the drive to design solutions for all of his customers. “This is a growing segment for us,” he shared. He is just seeing the tip of the iceberg for his place in the roll-forming industry. The ability to safely rack coils just once so they don’t need to be stacked, un-stacked, and re-stacked prevents damage to the coil and increases worker safety through less handling time. Working on a rack design to hold longer sheets of coil is also a high priority. “Our current max is 6′ x 12′, but we have another design for 72″ x 250″ (about 21′).” Cut coil can be deposited directly onto a metal pallet before being transported by forklift to the compact storage rack. “Roll-forming customers I’ve had cut their coil to length first, so they appreciate having a robust pallet system that protects the material,” said Bartel. Holes along the top side of the pallet can hold containment pins, so the sheets don’t slide against each other (a potential opportunity for damage) or slide off the pallet completely during transport. If completed products are not being shipped immediately, Big Steel Rack wants to solve your inventory storage and protection issues as well. While they don’t currently mass produce appropriately sized shelves for packages of rolled panels, they are innovating and adapting their designs as they get more involved in the roll-forming industry. “We could use the same pins in the perimeter of the pallet to contain all of the materials,” said Bartel. “I could also see creating lanes or bays that could hold formed panels, trim, or gutters.”

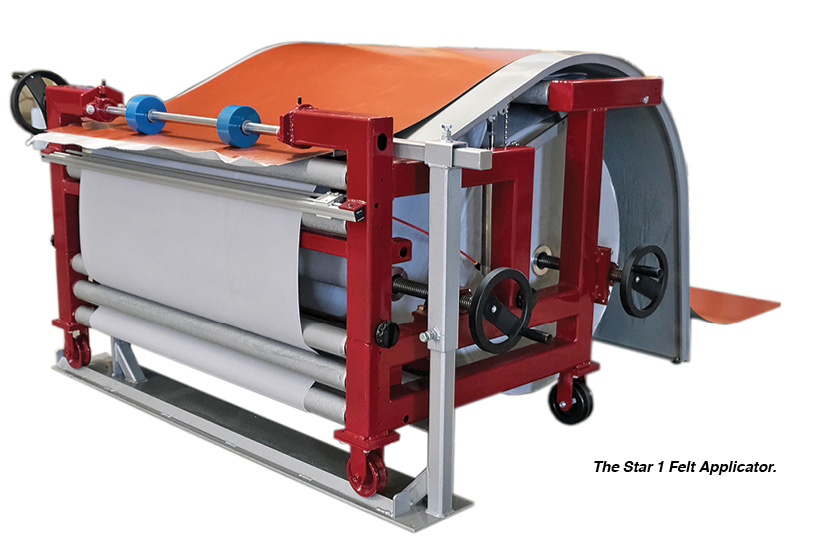

For a standing seam production line, the Ameripak SR-442SS series is designed to unitize and protect the panels to allow an increase in panel production.

Wrapping Solutions

Once the coil is run through the roll former, you’re left with bulky, sometimes oddly shaped panels that need to make it safely to their destination. Stacking and securing panels isn’t new, but Robert Bowlin of Ameripak has identified pain points in the process and created solutions. Typically, to prevent damage, the panels are wrapped with plastic sheeting, corner board, and banding materials right on sawhorses or a conveyor belt before they are moved to storage or a truck. “Once the panel is produced,” said Bowlin, “the roll-forming machine comes to a halt and now the process of packaging holds up the machine from starting on the next run.” Ameripak’s fully automated orbital stretch wrapper is installed right in line with the roll-forming machine, so the stack of panels moves smoothly from the roll former through the wrapping process without additional labor. “You can package quickly and make the roll-forming machine immediately available to run the next batch of product,” said Bowlin. Along with the fully-automated orbital stretch wrapper, Ameripak sells semi-automated systems and specialized machines for gutters and standing seam panels (which need to be stacked differently while packing).

For a standing seam production line, the Ameripak SR-442SS series is designed to unitize and protect the panels to allow an increase in panel production.