By RF Staff

From its beginnings as a one-man operation to an industry-leading global innovator in roll forming and value-added solutions, Samco Machinery is celebrating its 50th anniversary.

“I had no idea that Samco would ever evolve into what it has become,” says Joe Repovs, Samco founder. “You start out with a bit of a dream and your goal is to have a small shop where you employ five to 10 people. What I learned is that, if you do a decent job, the customer forces you to go bigger. You will grow with your customers. That is what happened with us. The customers forced us to go bigger and it rolled like a snowball.”

Samco Machinery, an ISO 9001-certified, vertically integrated company, provides customized solutions built around standard modules. “We work with the customer right from the initial discussion phase to understand their requirements and provide engineered-to-order solutions specific to those requirements,” Joe Repovs says.

Samco’s Project Management system provides a structured backbone to support the entire solution lifecycle, from product planning to engineering, through the various phases of manufacturing, installation and service.

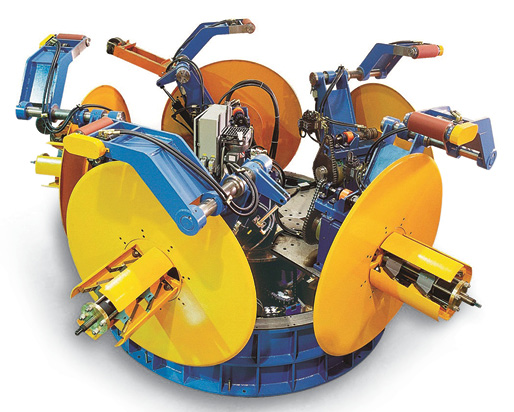

The Machinery division provides roll forming systems including uncoilers, coil cars, flatteners, roll form dies, roll formers, presses and material handling solutions for its global customers. The Rolling Division provides custom roll forming production services through its in-house rolling mills. Some of the industries the company provides solutions for include automotive, metal building and construction, transportation, storage, energy, and consumer products.

The company’s Fabrication Division is a CWB-certified precision fabricator offering engineering solutions, rapid prototyping and manufacturing services to multiple industries. It is currently servicing mining, military, automotive, construction, injection molding, press manufacturing and more. RF