Seeing an opportunity in the need for metal roofing suppliers, Harvey Zimmerman founded Hixwood Metal as a Graber Post Buildings dealership in Stanley, Wisconsin, in 1998. The company thrived by sourcing and reselling steel and post-frame buildings. Within just a few years, the business grew so much that Harvey needed assistance.

Help arrived in 2005 when Harvey’s brother-in-law, Paul Zimmerman Jr., and Paul’s father, Paul Sr., joined him in the enterprise. That same year, Hixwood Metal purchased equipment and began manufacturing its own panels and trims, facilitating even faster and stronger growth.

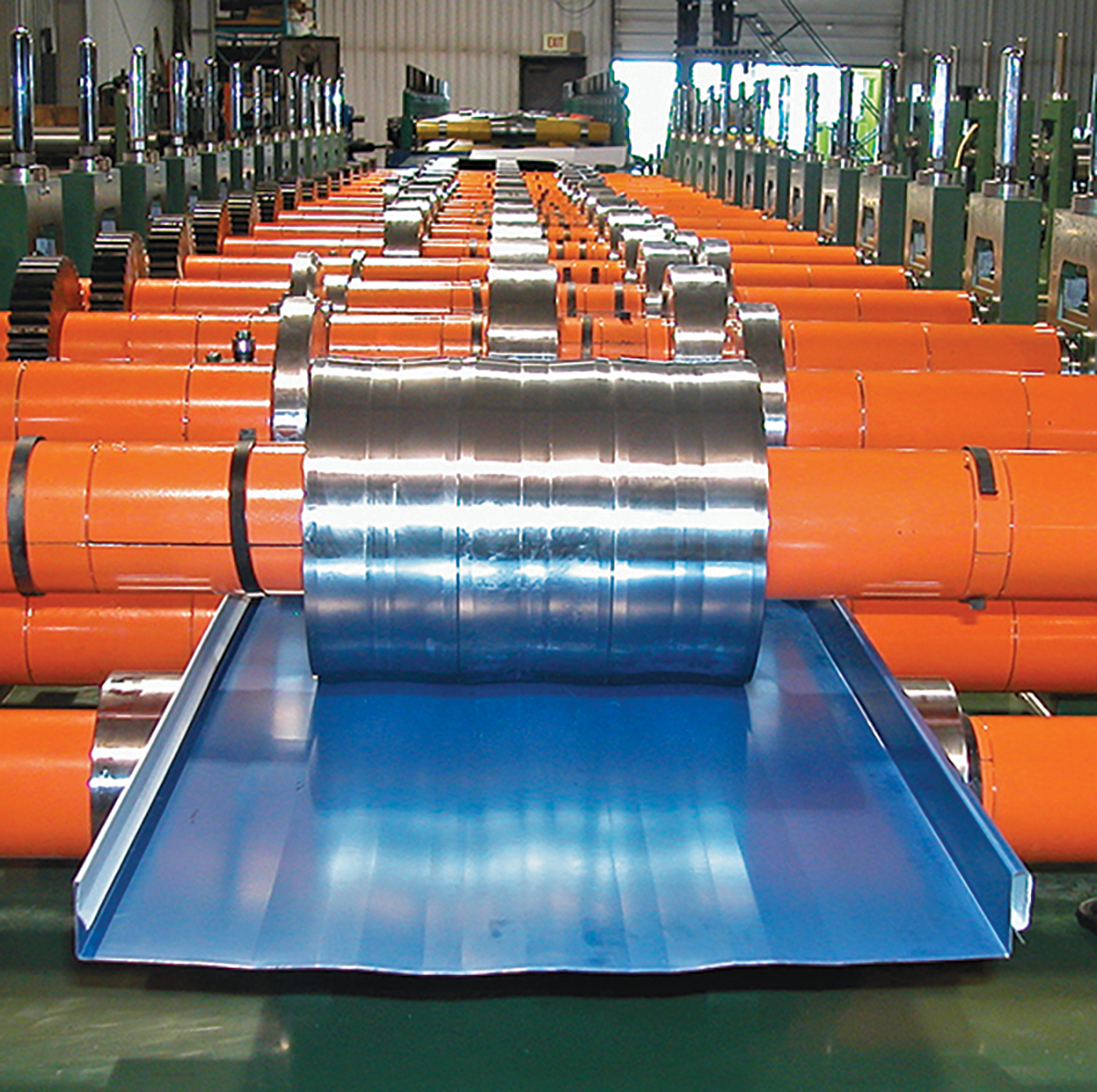

“All the initial equipment was new,” says Paul Jr. “We bought all the machinery from Bradbury.” The initial equipment investment in 2005 included a Hayes roll former from Bradbury and a Bradbury slitter and trim brake. Hixwood was now manufacturing and selling its own metal building components. The company also added lumber to its product lineup and began selling complete post-frame building packages.

The business started strong and experienced frequent growth and expansion, but there were always challenges. Paul recalls, “Somewhere in between all that came a period of time known as the Great Recession. We chose not to participate. We had growth throughout the entire time. We did some thinking outside the box and had volume growth throughout that whole period.” This shows the resilience of this industry and how an undaunted spirit can help take advantage of—or create—opportunities during challenging times.

In 2012, upgrades came in the form of adding a Bradbury roll former and another Hayes line. “And the original Hayes line is still operating,” says Paul Jr. “They’re good machines. We’ve had very good success with them.”

In 2013, the company needed more equipment upgrades due to increasing demand for trims. “We went with a Thallmann [from CIDAN Machinery] and have since traded the 2013 [folder] in for a new one and bought a second one. Those have worked very well,” Paul explains.

In 2015, Hixwood added a slitter with a coil farm. Since Bradbury didn’t offer it, the company turned to MetalForming to supply the new equipment.

At this point, the company was manufacturing panels and trims, offering lumber and its own brand of post-frame packages, operating a shed-building business, and running a nationally distributed coil sales business. The expansions and frequent equipment upgrades addressed production challenges. However, as the company continued to grow throughout 2017-2018, Harvey and Paul Jr. recognized there were limits to what they could accomplish. “We recognized that there were going to be needs going forward for the company that we wouldn’t be able to support as a family-run company. There were technological advances, the need to take care of employees, capital needed to grow… all those things. And then there’s the changing landscape of how business is conducted in the 21st century.”

With an eye on the future of continuing to supply customers while continuing to grow and improve the business, Harvey and Paul Jr. started looking for a partner. (Paul Sr. was no longer with them.) “We started looking for a partnership that allows us to continue what we want to do: provide high-quality products and services but have an owner that is very up to date with technological advances and can maintain the same percentage of growth,” explains Paul. After all, achieving 5% growth in a $5 million company is not as difficult as achieving 5% growth in a $100 million company.

The Hixwood Metal facility

near Stanley, Wisconsin in 2019.

Aerial view of the original Hixwood location on Hixwood Road in 2019. Photos courtesy of Hixwood.

Hixwood added a slitter and coil farm from MetalForming in 2015.

Hixwood General Manager Paul Zimmerman gives direction.

The future looks bright for future generations at Hixwood.

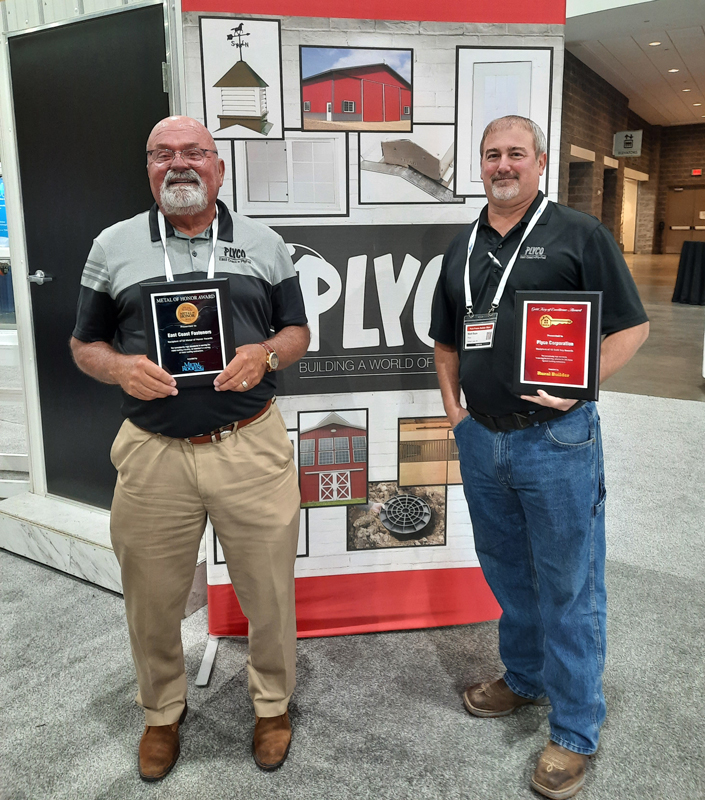

Hixwood Metal found its solution in Ambassador Supply. Randy Carman, President and COO of Ambassador Supply, who has been with the company since 2010, says that company values must align well with Ambassador to become partners. Potential brands need to have a cultural, kingdom, and financial focus. They need to have cultural alignment, caring about employees, their families, and their communities. Additionally, he says, “We are very much focused on seeing people have a relationship with God. No matter where they start, they should be moving towards [that relationship] in some way.”

The more tangible business factors Ambassador Supply looks for in potential partners are sustainability, scalability, and strategic leadership. Indicators that a company is sustainable include whether it takes care of its people, has a financial return, and provides good products to its customers. Scalability is determined by looking at factors such as competition, demand, company culture, and more.

The prospective company must also have strategic leadership. “Paul is clearly a strategic leader who sees what the company could be. We looked at what Ambassador could offer Hixwood and vice versa. We found all those things with Hixwood,” says Randy.

“It was clear they had a bottleneck for growth,” he continues. “Some of it was due to technology, some to their values and the organizations they affiliate with, and some to capital constraints from their extreme growth.”

Both companies agreed the partnership was a good fit. “Ambassador and Hixwood aligned beautifully,” declares Paul as he recalls 1 Corinthians 14:40: “Let all things be done decently and in order.” “Look at the Ambassador mission statement. It says we live for God, are active in the communities we live in, and take care of each other. It comes down to biblical principles that need to be lived out. This will ultimately bring your people and how we interact with them to the correct level. Keep everything decent and in order. These are fundamentals that should always be striven for.”

And so, in 2020, Ambassador Supply purchased Hixwood for their mutual benefit. The acquisition allowed Ambassador to grow its metal/post-frame business, and the buyout gave Hixwood the support it needed for continued growth.

Paul is excited about how things have changed at Hixwood over the last few years. He estimates his company was a decade behind in technology the day Ambassador Supply bought it. Hixwood had experienced explosive growth before being purchased, during which time it became evident that communication was a significant pain point. Technology was needed to mitigate these communication challenges.

The change was necessary, but it wasn’t without its challenges. “We were 10 years behind in technology when Ambassador bought us,” Paul recalls. “We needed to do catch-up work.” The Hixwood team went through a period of facing the unknown and adapting to the technology upgrades; however, they demonstrated they were up to the challenge.

“It didn’t take long for the team to see we were bringing in more resources,” says Paul. Tech updates included improved order tracking. Now, orders are tracked at every point from when the order is taken through in-plant production and even through delivery. When a project is shipped, tracking verifies every component is delivered to the job site. “We have better customer service. And at the same time, we’ve been able to maintain the quality we’re known for.”

“The quality of life today at Hixwood is better than before we sold,” Paul continues. “You can keep pushing the team, burning them out, and going through people to get stuff to the job site on time. Or you can step back and ask yourself, ‘How do we move correctly and make every move count through technology?’ Support from the new owner allowed the Hixwood team to work more efficiently.

“We used Ambassador’s resources to advance the company, but it was really our team that did the work. The team has again demonstrated their resilience in bringing us up to speed in three years with what was a decade’s worth of work.” Success wasn’t due to the effort of a few; it was hard-earned by the entire team.

“But I’d say that having a solid foundation at Hixwood and a solid foundation at Ambassador made challenges easier than if there hadn’t been those foundations,” Paul observes. Paul Sr. was an important part of setting the Hixwood foundation. “Harvey and I put a lot of work into it. But even as we interact with Ambassador, there are many things that we think back on that brought us here, including the leadership and guidance of my father. He had tenacious patience. Winning mattered, but it had to be done correctly and above board. How you operate your business every day matters. As of today, I can still see his fingerprints all over this company.” RF