There are basically three parts of the physical roll-forming system: materials going into the machine, materials going through the machine, and materials coming out of the machine. If you feel like you just can’t seem to get ahead of orders, is it a matter of improving how you handle these three parts of the system, or should you be on the search for a high-speed machine? While controls and software are an important part of the productivity discussion, we asked the experts for their ideas and opinions focused exclusively on coil handling machines and roll formers. We start by taking a cursory look at shop-based roll formers.

Metal Rollforming Systems (MRS) has three series of machines that cater to a wide range of customer needs. Bill Griffin, MRS owner and partner, said a small shop just starting out typically doesn’t need as much production capacity, and can save on initial startup costs by opting for the entry level Patriot series that runs at 130 feet per minute (fpm). The Signature line steps up to 150 fpm, and the Titan line runs in excess of 200 fpm.

Don’t know which is best? Griffin said MRS can help determine the best option based on what profile(s), how many profiles, turnaround time, and order volume.

“When they’re looking at upgrading for speed, a lot of customers are also thinking about expansion,” he said. “Expansion can include additional locations and or additional product or profile offerings.”

He noted that a common practice is to move the slower machine to the expansion location and purchase a higher-speed line for the main location. But Griffin said that’s not always the most efficient. On occasion a more efficient system may be to operate the machines side by side. “Now you can reduce the amount of color changes you’re doing in a day … If you can reduce your color changes, if you can group your orders together, and if you can get efficient at coil changeovers and order packaging and moving orders out, then you’re going to get a lot more throughput, thus increasing your roll former capacity.”

Griffin said pushing your machine “is a balancing act,” adding: a roll former is going to run at speed. I would say most people who get good at it, 70% of the day is operation, so if you are running an 8-hour shift, you’re only netting about 5 ½ hours of run time. If you’re able to get those hours up, you don’t have to put the capital expense into upgrading so quickly.” Infeed and outfeed improvements are the most cost-effective ways to speed things up.

A final interesting note from Griffin is on the issue of “sheet separation” or “sheet delay time” in production. “That’s how much time there is from when the machine cuts a sheet, to when it starts feeding the next one,” he explained. “This gives the operator time to catch and flush each sheet in the stack, but the time should be reduced as much as possible. As an owner you want to see that number minimized to maximize productivity. Every second of delay is a second the machine is not producing panels. That’s something to be very cognizant of.”

Acu-Form has found its niche in the 150 fpm and so offers one machine to cater to that market. When a customer asks about a higher-speed option, Acu-Form salesman Wayne Troyer starts by asking questions that will help them narrow down their true needs.

“When people say high capacity, I ask ‘what are you really looking for from your machine? If you’re running at 150 fpm I ask them, ‘what is your current run time on your machine; are you running 4 hours out of 8, or are you running 7 1/2 out of 8 hours?’”

If it’s the slower of the two, Troyer challenges them to look at options in how to get more run time out of their current machine. It might be as simple as having employees at the right location at the right time: “have someone there to change out coils, have someone there to package materials so the operator can get done with a job, enter in the next job, and keep running.”

If a business is running 8 out of 8 hours “gang busters,” [an unlikely scenario] then the discussion would change. While Acu-Form will custom-make a high-capacity machine for anyone with the money to afford it, there is another option if space allows. “I ask them: ‘are you crowded for room? Do you have room to expand if your existing machine is still running a good product?’ If it’s still running great, how about adding another machine beside it?” he said. “A second machine provides options to run two different orders at the same time.”

This allows a business also to offer better customer service for quick turnaround orders. “They will be better prepared to respond to a customer. They can still be running an order on one machine and if a customer comes in and says: ‘I messed up two pieces, can you please run this for me’,” you are able to accommodate them.

Troyer said a lot of machine owners don’t really know how much time their roll former is actually running. He challenges them to find out before making a major purchase decision. Acu-Form’s roll formers, along with many other brands, have the hours automatically calculated on the controller. “You can see exactly how many hours that machine has been running; you can see that this machine ran for two hours, shut down for an hour and so forth.”

Still, there are businesses that do need high-capacity machines. “A high-capacity machine absolutely does have a place in the market,” he said. “You get people running big orders like orders for big chicken barns, or they get orders from the big box stores. They’ll come in and say, ‘I want 20 pieces of 12-footers in red, green, and black.”

Even then, however, Acu-Form’s 150 fpm machine may be good enough. “All our machines come with a potentiality meter. A lot of times owners will run them at 75% to 80% capacity. When it comes to orders like that, they will turn them up to their maximum capacity.”

For small panel operators, the average run is around 100 to 120 fpm.

“At 150 feet a minute, you can run 3,000 feet an hour,” Troyer said. If calculated at six hours, it comes to 18,000 feet per day. In Acu-Form’s own market, Troyer said, “I don’t know anyone out there who has that kind of orders who needs that type of machine.”

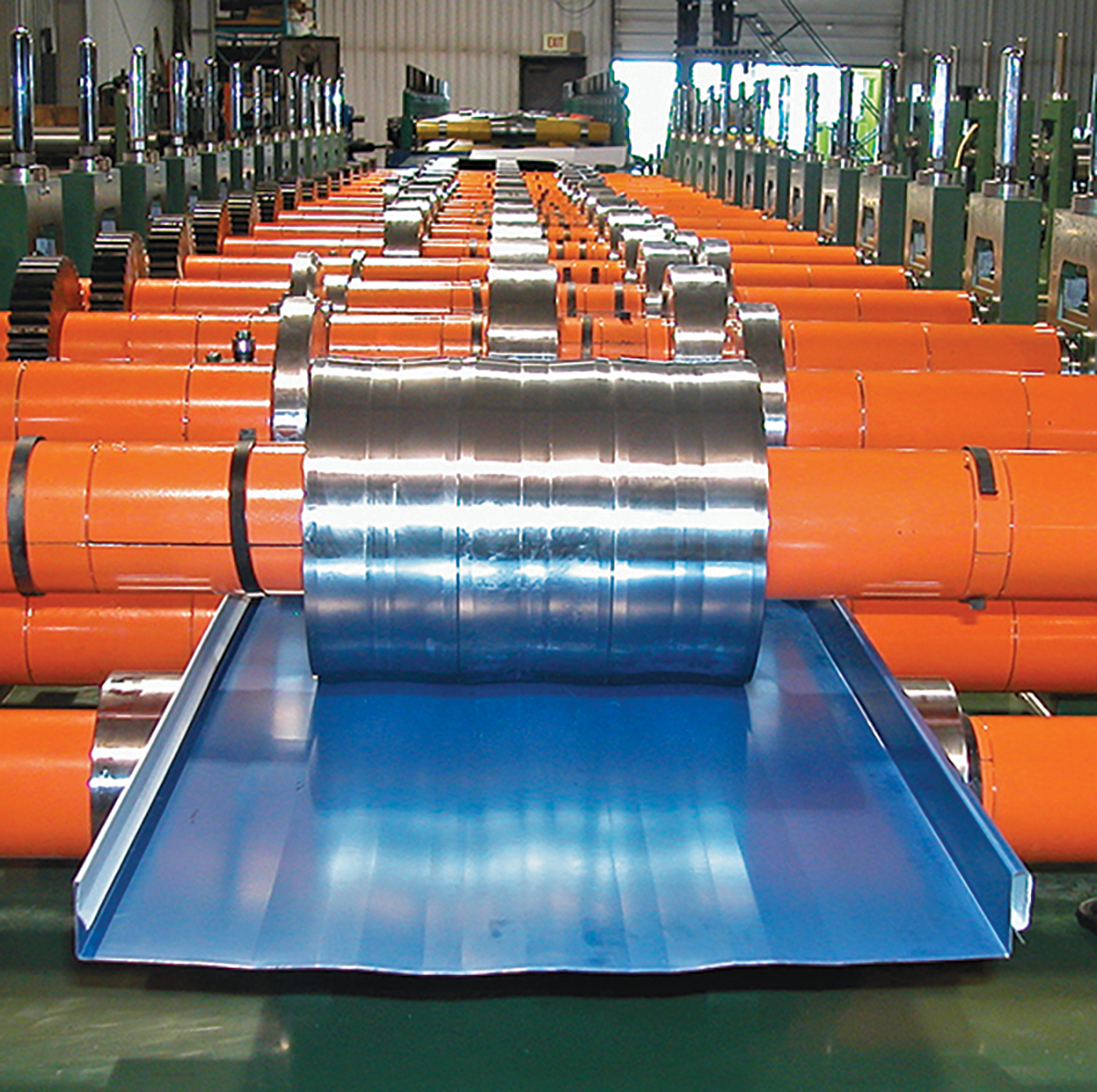

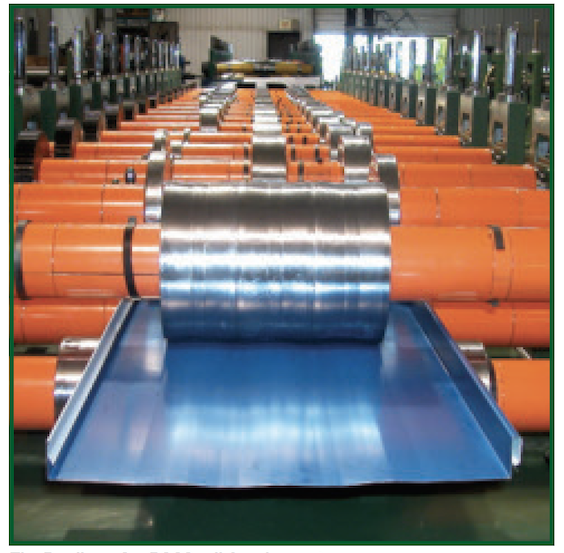

THE BRADBURY COMPANY serves a large variety of metal-forming industries with high-end machines, and can make just about anything a rollformer might want. But Ben Schmidt, Industry Sales Manager – Metal Buildings, Trim & Decking, said the typical owner of a Bradbury panel roll former doesn’t talk in terms of machine speed as much as they do output.

“When you talk about speeds in the 150 fpm, 100 or even 200 fpm, what the guys running this equipment care about is not necessarily the speed, but the throughput,” he explained. “For example, if they’re running 10 foot panels, they want to know: ‘how many 10 foot panels a minute can I get out of my machine, and what do I need to do to get more?’”

Bradbury customers typically experience higher volumes and multiple daily color changes. Color changes inherently slow overall production times. Schmidt said that a very productive shop in the panel industry, offering 20 colors, averages 50% of actual machine time.

“So out of an 8-hour day that machine is making panels 50% of that time,” he said.

Efficiency comes down to “how do we help guys change coil on the front side faster, and then also get the formed panels away from the machine on the exit side.”

Schmidt said productivity can be gained with how coil is cut. If you are currently using a “stop and cut or a hump and cut system (sometimes called feed to stop) that requires stopping, cutting, and restarting, you can amp-up productivity with a flying shear.” Schmidt pointed to Bradbury’s BOSS roll-forming system as a great option. It couples a Bradbury Orbital Servo Shear (B.O.S.S.™) to a new or existing roll former for high-speed, closed-loop shearing.

“Let’s say you have 12, 10 foot panels per minute on a fly system. On a stop-and-cut system you’re lucky to get 6-8 panels per minute. So we are literally able to double the panels that we can produce with a flying system, and we have not increased the roll former speed yet.”

The B.O.S.S. can be sped up or slowed down to accommodate the operator’s ability to catch panel as it exits the machine. It has a plus/minus cutting accuracy of 1/16th of an inch.

ASC MACHINE TOOLS also offers machines that cater to all spectrums of the panel roll-forming market and the varying speeds required to efficiently fulfill orders.

It begins with the Alpha Series, steps up to the Select Series and ramps up to the Classic Series. At ASC, rollforming speeds start at 150 fpm and can go up to 400 fpm which is the fastest line speed on the market. But Thomas Schwarzer, Regional Sales Manager, Northeast U.S. and Canada, joins in on the opinion that shops should not look solely at machine speed as the most important consideration when it comes to optimizing production.

“There are basically two worlds,” Schwarzer said. “The more affordable feed-to-stop lines and the higher budget flying cut-off lines. Smaller operations are fine with getting about 100 -110 fpm net throughput (not line speed). Larger manufacturers need higher speeds of up to 400 fpm to fulfill their demands. In between those two ranges are many variations of roll-forming systems. We’ve got to find out where you fit the best.”

A flying shear post cut is more likely suited to companies running at higher speeds of 200 to 400 feet/minute. Meanwhile, the feed-to-cut system continues to be the proper answer for many companies.

“Customers are most of the time looking for higher roll-former speeds because it seems to make the most sense,” Schwarzer noted. “Right out of the gate customers say, ‘I need 200 or 250 feet a minute,’ but sometimes it might be better to optimize the coil handling front end and/or the stacking systems first. It all depends on how many jobs you do a day; how many coil changeovers you do a day.”

As with everyone we spoke to, he encouraged owners to look at upgrading the front end and exit end machinery first. The capital investment could be smaller and customers might actually end up with the same or even higher net throughput production numbers.

By Sharon Thatcher for Rollforming Magazine

Additional resources: For more ideas on roll formers and productivity, see the article “Single, Dual, and Multiple Profile Panel Roll-Forming Lines: Things to consider when making your buying decision,” Fall 2020 Rollforming Magazine.

And, “Increase Your Productivity With These Inventory Management Systems,” Winter 2019 Rollforming Magazine.