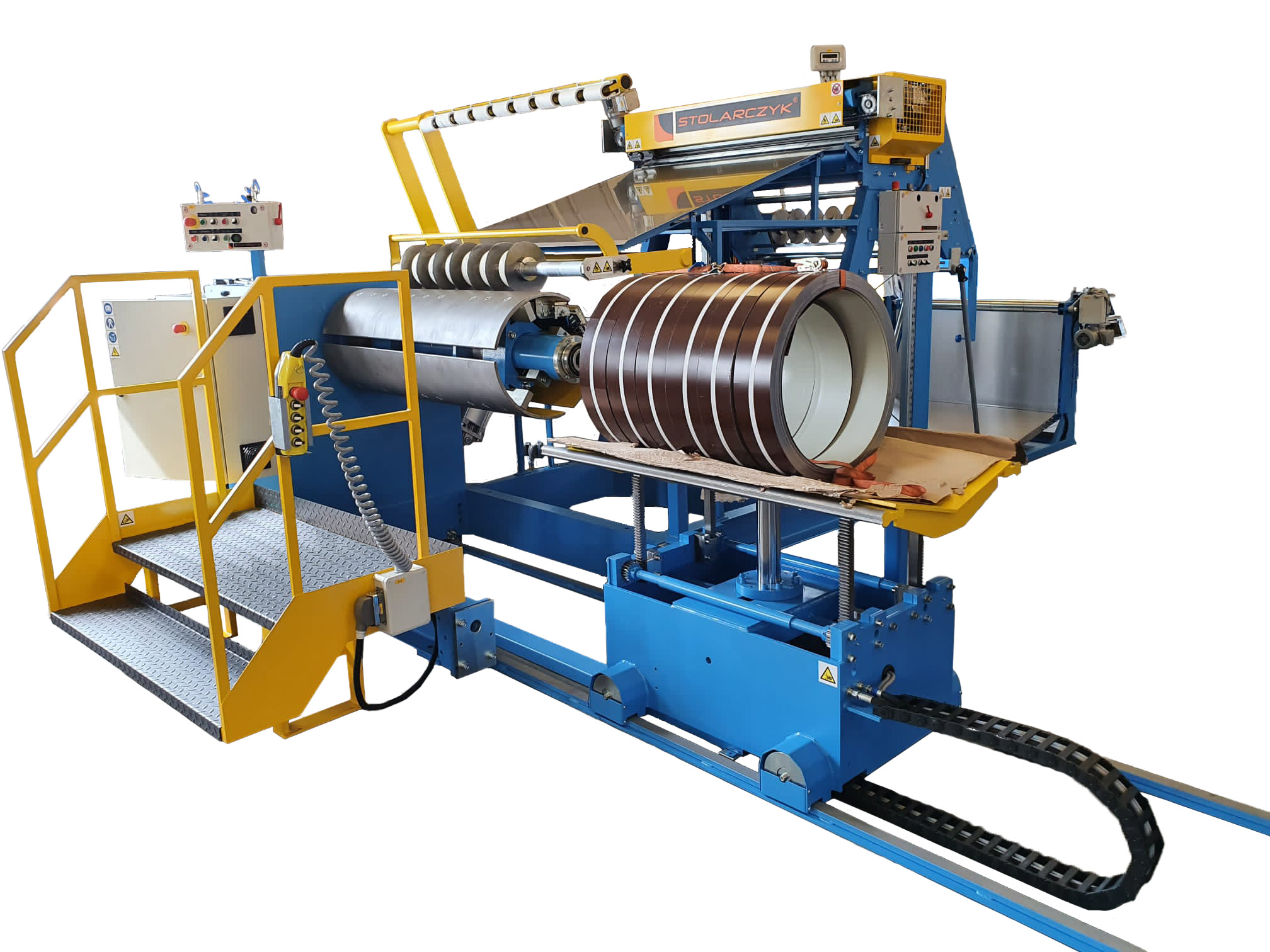

MetalForming Inc. recently announced it has added the new Stolarczyk Tension Stand and Recoiler to its product line. The Stolarczyk Tension Stand and Recoiler is highly efficient, easy to use, and reduces cost and lead times on custom coil widths. The tensioner clamps the material via pneumatic pressure with felt pads. The pressure gauge is fully adjustable for accurate clamping of material, while the loop is controlled utilizing a dancer arm. Shafts with separating disks ensure the material is properly guided to the tensioner and recoiler. Separating disks are included in the basic price for a total of six slits.

The recoiler has an open-frame cantilevered design for easy coil loading and unloading, and has an overhead guide with a separating disk to ensure the alignment of the coil. The recoil speed is controlled via dancer arm control but is fully adjustable via a rotary potentiometer.

The Stolarczyk Tension Stand and Recoiler can be customized to meet user needs. Some additional options are a coil cart for the recoiler, quick-change felt, a rotary exit shear, a pneumatic clamp for the recoiler, and an in-feed lifting table.