By Noli Cusi, Samco Machinery

Every year, it seems roll forming manufacturers are being asked to improve turnaround, speed up roll forming capabilities, using heavier and high-strength materials while still focusing on safety.

No problem, right?

Well, there are solutions, improved equipment, larger equipment and better technology. Material handling equipment in front of and at the end of a roll forming line, can increase production and meet the demands of today’s customers as well as tomorrow’s customers.

Out front

Front end decoilers certainly can help speed up operations. A decoiler — or uncoiler — feeds the coil into the next station of the process. Decoilers can be single-ended or double-ended, handling coils up to 40,000 pounds.

A decoiler can be used to change over coils as material is used. The single-ended decoiler is slower, but requires less space on the floor. Decoilers can also be designed to hold multiple coils of different gauges or color, allowing operators to quickly switch coils and keep the roll forming lines running.

A coil car and upender allows for coil to be safely moved, lifted, turned into position and loaded on the coil car while the decoiler is still running. The coil car and upender can also unload partially used coils.

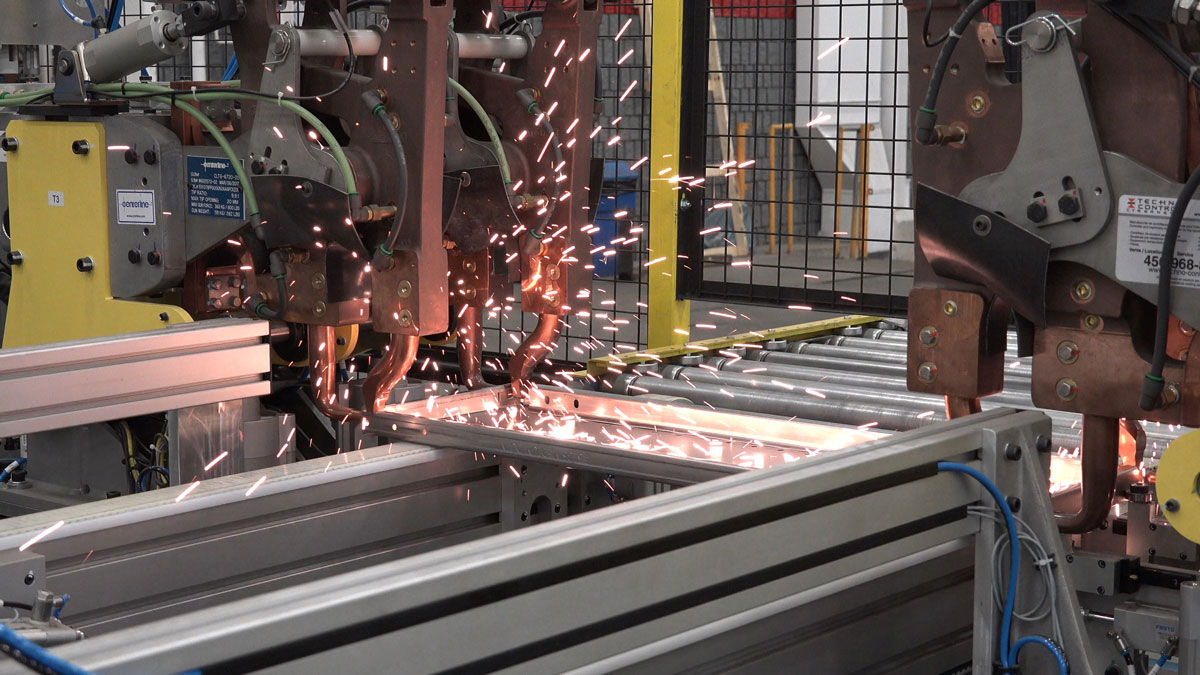

Coil coming off a decoiler may feed an end shear and a pre-cut operation at the front end of the roll former. An end shear welder allows the operator to join the leading edge of the new coil to the trail edge of the running coil to save time feeding new coil through the entire line. It not only saves downtime, it limits damage due to manual feeding, thereby reducing scrap. Using an end shear welder allows for an uninterrupted feed, increasing up time by 96 percent.

There may also be an accumulator, where coil is accumulated and then fed into the roll former. Once the entire coil is in the accumulator, new coils can be loaded on to the decoiler without stopping the roll forming line, saving anywhere from 10-15 minutes per coil change. Coil is automatically fed into the roll forming machine.

Out back

Various end-of-the-line material handling options are also available to increase efficiency with finished products at the end of the roll forming process.

A nester collects and nests a bundle of finished products and sets them up for shipping. Bundlers automate the handling of mini-bundles and automatically build pre-programmed master bundles ready to be shipped based on orders. A stacker gathers finished parts and stacks them for movement with a forklift. Instead of humans picking up long, heavy parts 20-25 feet long, they are handled by a machine which improves safety and assures products are packed in correct quantities.

Once parts come off a roll former and are bundled or stacked, proper packaging is needed to ensure parts arrive safely without damage. Packing systems include shrink wrapping, strapping or bubble wrapping to protect products being loaded and unloaded from a truck.

New world

In a post-Covid world, a roll forming line with material handling equipment will allow workers to work safely, 6’ or more apart. Without material handling, more workers are needed to do the job and those workers more likely will be required to work in a closer proximity to each other to complete their jobs.

It’s also important to note that an experienced roll forming manufacturer will train operators. Customers should be encouraged to send an operator to the manufacturing plant to observe the machine being tested and have an opportunity to check out different challenges and gain an understanding of the machine or line, helping the operator get things up and running safely, as soon as possible. RF

Noli Cusi is the Vice President of Operations at Samco Machinery (www.samco-machinery.com). Samco manufactures roll forming machines, uncoilers, roll tooling, presses, and material handling solutions servicing a multitude of customers worldwide in varied industries.