Editor’s Note: This article was originally published in the October/November 2004 edition of Metal Roofing Magazine. These photos were taken 20 years ago. We recognize that roofers shown are not using appropriate safety equipment. Shield Wall Media encourages everyone to use recommended safety equipment.

In the world of metal roofing contractors roll forming their own panels, there is no such thing as a typical workday. Various tasks will be repeated, to be certain: estimates will be given, materials purchased, jobsite problems solved. But every day will bring its own unique challenges: coil arriving at the last minute, two crews working 30 miles apart both needing the company’s one operational roll former, a wrong turn on the highway.

7 a.m.

Walking into the office of Dan Perkins Construction at 302 North Main St., Ishpeming, Mich., a visitor is greeted by a cloud of cigarette smoke. Dan, office manager Larry Clemo, and his foremen have been planning where the company’s two crews will be today — a tear-off deep in the woods about 20 minutes away, and a re-roof about an hour away in Skandia.

7:30 a.m.

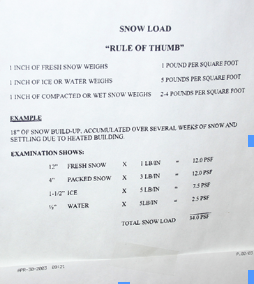

Dan covers a lot of ground in the early morning sunlight: snow loads (key in his snow belt region), metal roofing details (he’s hoping to compile a photographic encyclopedia), oil canning (referring to an article on the subject in the last issue of Metal Roofing, Perkins says “Oh my god, that picture was just nasty!”), the recent TAMKO purchase of MetalWorks (Perkins has done a number of sharp jobs using MetalWorks’ shingles), and photovoltaics. The last issue is a particular labor of love. A big believer in developing alternative energy sources, Dan has worked extensively with Uni-Solar developing laminate PV systems that nestle in the pans of standing seam metal roofs. He’s done about five PV installations nationwide, and after the summer/fall busy seasons pass, Dan plans on resuming development of some of his latest ideas.

8:30 a.m.

Breakfast just around the corner at Aunty Kathy’s. Over eggs and several cups of coffee, Dan talks about what a rough year it’s been for the steel industry, and how several of his suppliers have faced challenges meeting delivery dates and price points. It’s tough being located in one of the northernmost outposts in the country. Ishpeming is a seven-hour drive from Chicago, an eight-hour drive from the Twin Cities, and a five-hour drive from Milwaukee. Perkins’ shop isn’t on the route for many semi trucks hauling coil cross country.

8:55 a.m.

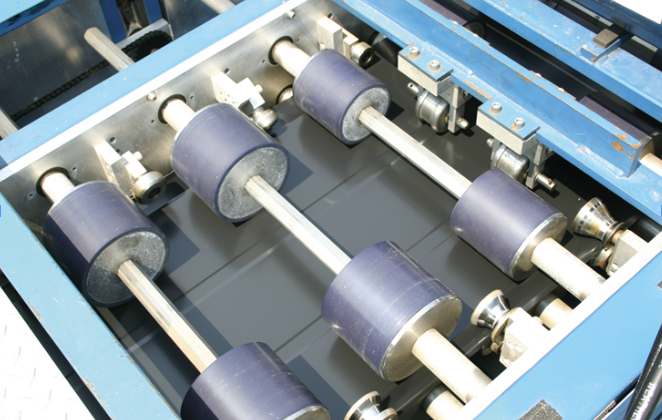

A new Metalman roll former from Englert sits in the parking lot outside Perkins’ office. Dan and several of his guys made the trip down to Chicago late last week to pick up the machine. Dan is in the process of registering and insuring the new machine, but in the meantime the company continues to use its Roll Former Corporation machine.

9 a.m.

Dan fills up his truck at a local gas station, and the bill comes to more than $50. The summer’s high gas prices have hit Perkins’ pocketbook hard. Given the Upper Peninsula’s sparse population base, crews drive long distances most days, translating into monthly gas bills in the thousands of dollars. Trucks are a necessary evil in Perkins’ eyes. From his perspective as a small business owner, the Bush administration’s tax relief for large vehicle purchases last year was a terrific incentive to upgrade equipment. As an environmentally conscious American, he loathes the idea of more vehicles guzzling gas at 15 miles or less per gallon hitting the road.

9:15 a.m.

About 15 minutes away from his office, Dan’s cell phone rings. It’s a delivery guy looking to drop off a large order of RoofTopGuard II underlayment from Drexel Metals, but the office phone went unanswered. Dan tells the driver that Larry is probably just on the other line, but that if he can’t get a hold of him he will head back to the shop and help unload. Dan calls his office phone, which goes to the answering machine, so he turns around and heads back.

9:30 a.m.

Dan arrives at the shop, only to find Larry helping the delivery driver unloading the underlayment. Perkins Construction’s shop has all the trappings: coil in many different colors, leftover trim, various brakes and other bending machines, metal roofing accessories like fasteners, sealants, and underlayment. The company’s office and shop are about a block away from one another, and Dan would like to eventually have both in the same location, to improve early-morning productivity.

10 a.m.

A short detour takes us past several MetalWorks jobs Dan has done in a subdivision near Negaunee. Dan’s cell phone rings again, and it is arguably his most important call of the day. It’s his daughter, who while baby-sitting her younger sister has discovered the hard way that the baby has graduated to a larger size diaper. Dan says he will work on getting some larger diapers.

10:15 a.m.

On the way to visit his first crew of the day, Dan stops at a log home to show some details. Log homes are tricky, since they don’t settle at a predictable rate, and while Dan would do certain details differently nowadays, overall he is pleased with how the roof looks.

10:30 a.m.

Dan arrives at the White Bear Road jobsite. It’s one of Dan’s favorite types of jobs, a ranch-style residence with little pitch and few tricky details, save for the potential move of a plumbing stack. The crew has completed tear-off of the existing ag panel roof in about 1-1/2 hours, less than half of what Perkins had estimated, and everyone is pleased at being so far ahead of schedule.

But this presents a potential problem: the new roof will be teal, a color Perkins has never used before, and the coil needed to start on the trim has not yet arrived. It is the first order Dan has placed with Englert, and it is supposed to arrive today. Joel Vickstrom, the foreman and a part owner of the company, says he’ll bend the trim tonight, but asks Dan to double-check on the order’s status.

11:30 a.m.

Dan heads off to visit his second crew. He places a call to his contact at Englert, and inquires about the status of the teal coil shipment. Much to his relief, the shipment has arrived, and Larry has taken care of it at the shop.

Noon

Things are progressing well on the Skandia job, a black standing seam residential project, but with more pitch, and laborious details like a canopy over the front door and a chimney. The chimney is a standard detail and poses little problem for the guys on the roof, but the canopy is trickier. The ridge runs into the bottom of a window overlooking the canopy, meaning the standing seams will not tuck under the ridge cap.

For the longer runs on the main roof sections, crew foreman Jeremy Lambert runs panels by himself on the Roll Former and hands them up to two workers on the roof, who fasten them and seam them using manual tools. Jeremy eschews the use of a computer and shear that come with the machine — he says he can do it quicker, and make cuts and bends on the next panel that a typical shear can’t.

1:30 p.m.

It’s off to Escanaba, about an hour away, to pick up two repaired Bostitch roofing nailers the guys find invaluable. The city is not in Perkins’ normal coverage area, so the tiny repair shop takes awhile to find.

2:30 p.m.

Lunch at Hereford & Hops in downtown Escanaba, where Dan talks about how he got into metal roofing. Originally from New England, he moved to the UP so his wife could be closer to her mother. After starting as a remodeling contractor, Perkins branched into metal roofing when he saw its potential as a residential product. At first, he installed through-fastened panels. There is no shortage of ag panel on UP homes, as the product fulfills two prime concerns for the region: durability and snow shedding ability.

But several years ago Perkins switched to standing seam and found himself bidding higher-end homes and commercial jobs. Running standing seam panels from jobsite machines has been a learning experience, and Dan has adapted the lessons he learned from Vermont roll former Rodney Rood to fit the demanding UP climate. The standard Dan Perkins Construction recipe for roll formed panels has evolved to this: 24-gauge steel cut from 20-inch sheets into 17-inch pans, with 1-inch major ribs and two minor ribs, ideally installed over a roof deck of foam board insulation and 5/8-inch OSB or plywood. It’s all in the name of controlling oil canning. “Oil canning is a huge industry issue, and it’s all of our responsibility to do what we can do to control it,” Dan says. “The future of our industry is at stake.”

3 p.m.

Leaving Escanaba, Dan gets a call from a customer up in Copper Country, an hour or so north of his office. The customer wants to talk about a design idea for his roof, adding a cupola.

3:15 p.m.

Dan gets a call from his lawyer regarding an upcoming case. Typically, Perkins does not go to court to settle disagreements, but this case is different. A customer did not pay him for work performed, and after Dan took her to court, she countersued him for damages and defamation of character. To hear Dan describe it, the case is frivolous and ridiculous, and although settling out of court would have cost him just as much money as winning and paying legal fees, it’s a case Dan feels he has to see through to the end, a matter of principle.

But there’s been a snag. The trial is scheduled for Thursday, and Dan’s key witness, a local man who was also not paid by the plaintiff for odd jobs performed, needs to be served a subpoena — today! Complicating the matter, Dan can not serve the subpoena, it must be done by one of his employees. Dan knows just the guy for the job — John Lehigh, who’s working at the White Bear jobsite — and tells the lawyer he’ll work on a solution. He must be back in Marquette by 5 p.m. to pick up the subpoena from the law office.

While talking to his lawyer, Dan takes a wrong turn, and drives about 15 minutes in the wrong direction.

4 p.m.

Dan gets a call from his wife, inquiring about his current status. They have company coming over for enchiladas at 5:30 p.m., and Dan is supposed to pick blueberries after supper. Still about an hour from Marquette, making those appointments on time looks iffy at best.

5:05 p.m.

Arriving at his lawyer’s office five minutes after it closes, Dan sprints to the back door and picks up the subpoena from an employee who stayed late.

5:25 p.m.

The guys at the White Bear jobsite are wrapping things up for the day, and after giving John subpoena delivery directions, Dan surveys the scene and finds things are going great. About half the roof is properly decked, and the other half shouldn’t take long tomorrow morning. Joel says the crew will be ready for steel by noon Wednesday.

The challenge: Jeremy’s crew, while making steady progress, had not been scheduled to be done with the Roll Former by noon Wednesday. And the paperwork for the new Englert machine is not yet complete. Each potential solution has its drawbacks. Jeremy’s crew could measure, cut, and drop all the remaining panels for the Skandia job Wednesday morning, but the roof has so many irregularities that it will not be a quick task, and storing the panels onsite would be difficult. The Englert machine could be rushed into action, but registration and insurance are still pending, and the crew has not yet used the new machine.

5:40 p.m.

Dan calls Englert to inquire about the status of the registration papers, and is told they are in the mail. He asks that the papers be faxed to his office tomorrow morning.

5:50 p.m.

After trading voicemails, Dan talks with Jeremy about finishing with the Roll Former by 11:30 a.m. Wednesday to bring to the White Bear crew. Jeremy says he’ll see what he can do.

6 p.m.

A full work day in the rear view mirror, Dan drops his companion for the day off outside his office. Enchiladas, blueberries, and diapers await, and tomorrow’s challenges roll forming metal panels have not yet been answered. But if Tuesday is any indication, Dan Perkins Construction will take it all in stride.

Metal Roofing Magazine was born as a supplement to Rural Builder magazine in 1999. A few more supplements were published in 2000. In 2001 it was elevated to a stand-alone magazine, and today it is over 20 years old.

“Flashback” articles (articles that were published ages ago) are published in every edition of Metal Roofing. Rollforming is still too “new” to have flashback articles of its own … but we came across this one and thought you’d find it of interest.

If you’d like to see more articles from “olden days,” drop us a line and let us know.

— Karen Knapstein