Industry 4.0: How it has changed the metal forming industry.

There has been a lot of buzz about Industry 4.0, and how it is going to change the face of manufacturing. We’ve all read the very promising and lofty statistics such as a 30 percent increase in productivity, and a two-year return on investment (ROI). The “smart factory” has been held up as an ideal that appears futuristic and unattainable to most metal fabricators. Before you dismiss Industry 4.0 as nothing more than marketing hype, let’s talk about past industrial revolutions and where we are today.

Industrial Revolutions Past, Present & Future

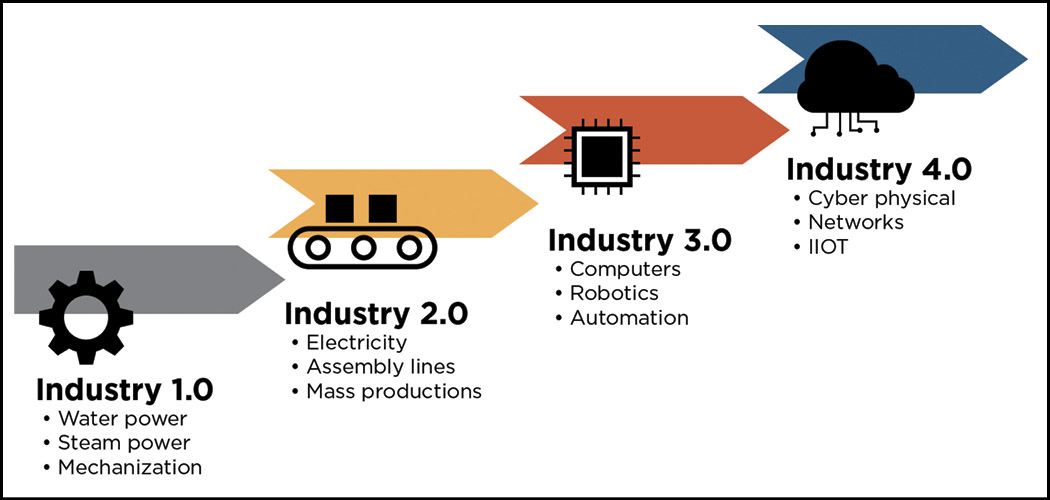

There have been four main industrial revolutions that have occurred throughout history. The first and third industrial revolutions are said to be disruptive, resulting in significant changes to the manufacturing landscape.

1. Mechanization through water and steam power.

The first industrial revolution was very disruptive and revolutionized industry by moving from skilled artisans making goods by hand to less skilled workers using machines powered by water or steam.

2. Electricity powers mass production and assembly lines.

Building on the first revolution, electricity replaced water and steam as a power source during the second revolution. Assembly lines were developed.

3. Computerization and automation.

Similar to the first revolution, computers brought disruptive change to manufacturing, enabling the introduction of robotics, improved precision and computer numerical controls (CNCs.)

4. Cyber physical systems, IIOT.

The digital age brought about smart factories and the Industrial Internet of Things (IIOT) where systems and processes integrate and real-time data becomes a key component of decision making.

To boil down Industry 4.0 to its most simple form, it is the next step in the evolution of computerization and automation. Industry 4.0 ushers the increased digital connection and integration between devices. With this increased connectivity comes the ability to compile and analyze data in real time, and to make meaningful decisions based on this data.

Is The Metal Forming Industry Ready For Industry 4.0?

You may be reading this and think that the metal forming industry is nowhere near ready for Industry 4.0, but this is not the case. Metal fabricators nationwide have already taken advantage of the many benefits of Industry 4.0.

Unlock Machine Data and Improve Analytics

One of the features of Industry 4.0 revolves around hyper connectivity: how machines are connected and how they communicate with each other via the web.

In the past, each machine or system created and stored data in its own data silo, making it difficult for manufacturers to develop comprehensive reports in a timely manner. Hyper connectivity removes data silos and gives us visibility into just about every aspect of the manufacturing process.

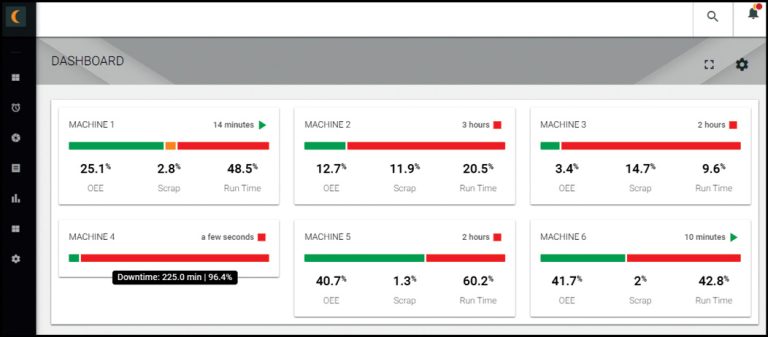

Hyper connectivity also makes it possible for manufacturers to experience real-time reporting, with valuable “live” data. In addition to the convenience of at-a-glance dashboards, live data allows manufacturers to be more nimble: to respond quickly to situations as they arise and measure the effects of their decisions without having to wait a day to review reports.

Machine Controllers Are Perfectly Positioned To Compile Valuable Data For Metal Manufacturers

Many of today’s new controllers used in metal manufacturing have the capability to compile critical manufacturing data such as yield, scrap, speed, run time, downtime and so much more. Instead of using hand-written logs that are labor intensive and have a large margin of error, Industry 4.0 adopters rely on controllers to accurately compile data, without requiring any downtime from the operator. All this data from controllers can then be fed into an online Production Management Software (PMS) solution to be accessed through dashboards for quick at-a-glance view of operations or analyzed further at a later date.

Metal manufacturers can then use this data to identify manufacturing trends, bottlenecks and manage inventory. This data is critical in scheduling, predictive analysis and also continuous improvement activities. Metal manufacturers are also integrating their PMS and ERP systems, bringing production data closer to sales and customer data. They do this by providing:

• Accurate reporting without disrupting workflow;

• Comprehensive reports give manufacturers valuable insights into how efficient their processes really are running;

• Dashboards with real-time data allow manufacturers to make critical decisions and to immediately see the impact of the decisions;

• Monitor Overall Equipment Effectiveness (OEE) of all machines; and

• Historic data provide manufacturers effective tool target and measure continuous improvement efforts.

Maintain Quality Proactively

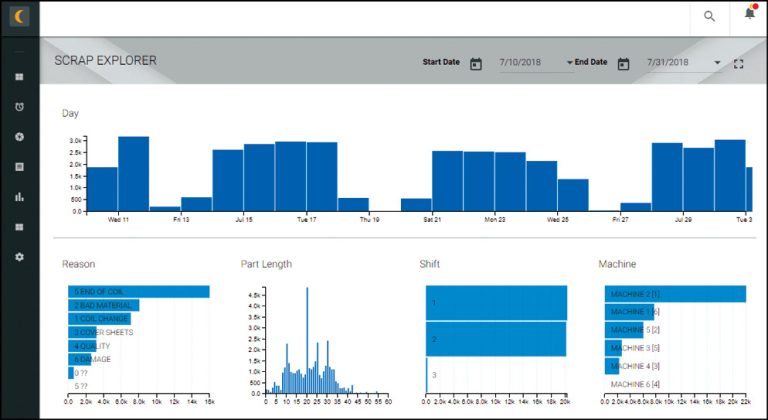

In the past, the only way to review and address quality issues was to analyze post-production results and reports, making quality control a very reactive exercise.

We have all seen how one small glitch in the manufacturing process can cause a fault that cascades to larger quality errors that drive up production costs. With Industry 4.0, real-time alerts notify manufacturers of specific events, or when out-of-tolerance thresholds are exceeded. These alerts allow manufacturers to take action and make the necessary corrections to address the tolerance issue earlier in the process.

Metal Manufacturers Use Alerts And Quality Audits To Maintain Production Efficiency And Standards

Controller-driven data capture compiles a surprising amount of data on almost every aspect of the manufacturing process. Alerts can be customized to trigger when issues result in unforeseen delays in the production schedule. Advanced alerts allow manufacturers to take action as necessary to maintain the production schedule needed to meet sales demand.

Manufacturers can also implement quality audits to ensure the right material is used with every job, parts are produced at the right length and quantity and more.

Depending on the nature of the issue, quality audits can be set to halt production until after the situation is satisfactorily addressed. By enforcing the quality audit, manufacturers are able to establish and maintain quality standards by these means:

• Configurable alerts bring attention to any issues that could delay production before it becomes a problem;

• Quality audits help ensure the right material, length, color and quantity for every job and reduce error and scrap; and

• Enforceable quality audits help ensure adherence to company policies.

Improve Efficiency

One of the digital transformation’s biggest gains in the manufacturing industry is the increase in efficiency. In fact, according to the American Society for Quality, 82 percent of the manufacturing companies that have digitized operations report that IIOT has resulted in increased efficiencies, lower overhead and higher profits.

Industry 4.0 Technology Helps Metal Manufacturers Gain Efficiencies In Many Ways

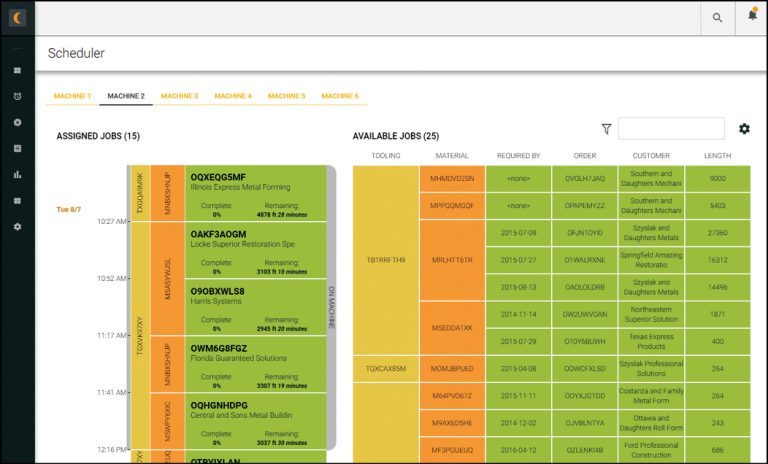

Hyper connectivity has helped metal manufacturers streamline processes in multiple ways. For example, by removing the task of keying in orders from operators, Industry 4.0 technology has helped keep machine operators focused on making parts and not keying in orders at the machine.

Other technology innovations such as bar codes and radio-frequency identification (RFID) has helped manufacturers track the movement of material through the manufacturing process, giving manufacturers a better view of material usage and scrap.

IMPROVE ORDER ENTRY PROCESS

• Streamline ordering process and remove the task of keying in orders away from operators;

• Allow operators to focus on running parts; and

• Control production process and job scheduling to maximize productivity.

IMPROVE SCHEDULING PROCESS

• Up-to-date schedules reflecting real-time information allow manufacturers to make accurate manufacturing forecasts; and

• Provide manufacturers with more control over scheduling by removing operator’s ability to cherry pick jobs.

IMPROVE INVENTORY MANAGEMENT, REDUCE SCRAP

• Material bar code or RFID system accurately tracks coil movement and usage;

• Warehouse management system ensures on-time delivery of material and reduces production delays; and

• Quality audits prevent wrong material errors and improve accuracy of orders.

Ensure Compliance & Reporting

Hyper connectivity has without a doubt enhanced the accuracy and speed of reporting for manufacturers. Add real-time data to the mix and Industry 4.0 manufacturers experience analytics that are actionable, accurate and relevant. Not only has reporting improved with Industry 4.0, manufacturers now have an ally when it comes to compliance. Internet 4.0 tools can be used to help track and implement compliance reporting in a multitude of scenarios.

Enhanced Compliance and Compliance Reporting for Metal Manufacturers

Gone are the days of relying on operators to turn in log sheets recording parts, scrap, downtime and a long list of other metrics. Metal manufacturers no longer need to wait a day for office personnel to key in all the logs in a timely manner, and hope operators were accurate in their reports.

Industry 4.0 technology has made reports available any day, any time, all from a convenient web browser. Plus, since data collection is automated with the help of controllers, Industry 4.0 has eliminated human error in data collection.

Industry 4.0 has also helped manufacturers develop compliance strategies on the plant floor.

Quality audits can be used to deploy successful compliance plans by mandating specific safety protocols before production can proceed. Since quality audits are configurable, they are limited only by the manufacturer’s imagination. Quality audits have been used to not only ensure compliance to safety procedures, quality audits can be configured to encourage employees to adhere to a host of company policies.

Industry 4.0 Is What You Make it

If you are disappointed that you have not implemented any Industry 4.0 technology, don’t worry. Try not to focus on if your facility has embraced Industry 4.0. Instead, focus on what you can do to run an operation that is more profitable and efficient, and how to gain better visibility into your manufacturing operations. As you strive for better efficiencies and visibility, your manufacturing facility will naturally begin to experience more and more of Industry 4.0. For a more in-depth study on Industry 4.0 and how it affects the roll forming industry, check out AMS controls website at www.amscontrols.com.

AMS Controls has a complete production management system to optimize the manufacturing of panels, purlins, trim, studs and more. Since 1977, AMS Controls has sold 13,000+ controllers worldwide.

Industry leaders have chosen AMS Controls’ complete production management system to optimize the manufacturing of roll forming cut-to-length panels, purlins, trim, studs and structural products. Their solutions can be used with any brand of roll former or folder to effortlessly eliminate mistakes, manage coil inventory and track production.

For more information on anything presented in this article, please contact AMS Controls at 314-344-3144 or visit www.amscontrols.com. RF