Tom Hulsey, ST Fastening Systems, To Be Inducted At CRS

■ By Sharon Thatcher

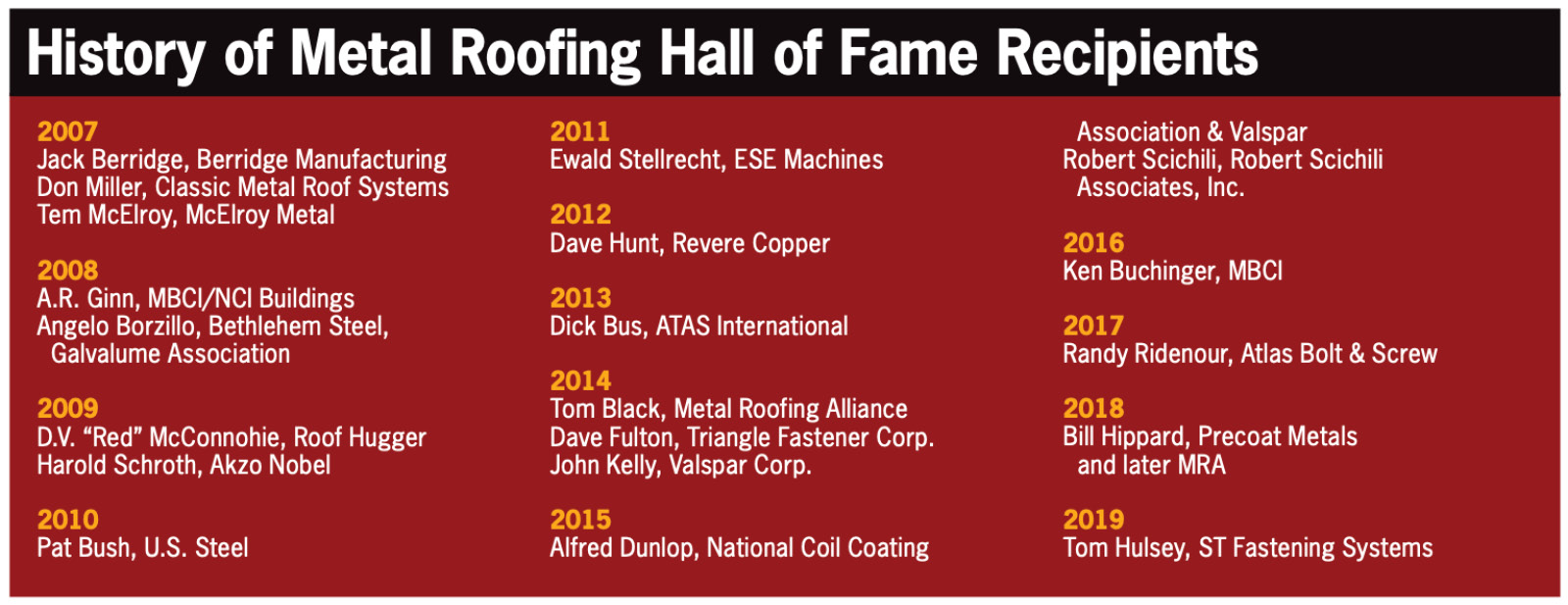

Tom Hulsey, Vice President of Engineering for ST Fastening Systems prior to his retirement, has been named the recipient of the 2019 Metal Roofing Hall of Fame, sponsored by Metal Roofing Magazine. He will be inducted on December 13 at the Construction Rollforming Show in Cincinnati.

Hulsey, 80, retired in 2014 after a 50-plus year history of developing some of the most significant fastening products and systems for the metal industry, approximately 14 of which were patented.

A native of the small town of Ladonia in northeast Texas, Hulsey graduated from the University of Arkansas in 1962 with additional post-graduate studies at Penn State University.

He started his own residential drafting service following graduation, while teaching architectural drafting and design.

“Varco Pruden called and said we would like your help,” he says. “They wanted to develop a product manual that illustrated all their products in a graphic form – line drawings – so I developed a product manual for them.”

The product manual led to a construction manual, which led to a pricing manual, which led to VP asking Hulsey to join the company full time in its newly formed Research and Development department in the late 1960s.

His career evolution continued while in the R+D department where he developed fenestration units for windows, doors, and one particular project for a self-drilling fastener.

Next came a company called Construction Fasteners, (forerunner of today’s SFS intec). He joined the company in 1974 to set up their engineering, quality control, and technical service departments. He also started developing fasteners on a regular basis.

Several of Hulsey’s inventions led to patents in the 1980s and 1990s. One was a flexing type fastener for attaching fiberglass roof insulation. Another fastener was a bi-metallic screw with a stainless steel upper body that didn’t rust, and a carbon steel lower body that could be hardened for drilling. Another yet was a zinc aluminum head fastener on a steel screw that wouldn’t red rust. It was self-drilling and self-tapping, and the first of its kind, moving the metal industry away from the traditional carbon screw that did rust.

The screw’s self-tapping feature was monumental for saving time. “When I first started in the metal building industry in the mid 1960s, the industry standard was self-tapping fasteners,” Hulsey says. “Installation required pre-drilling a hole with a drill then driving the screw with a screw gun. It required two tools on the roof. A self-drilling screw had been introduced in the early 1960s as a hardened steel fastener that required electroplating to retard red rust formation on the head of the fastener after installation.”

When he moved to ST Fastening Systems (then called Sealtite), in 2001 to become Vice President of Engineering, he would develop a similar alloy head screw outside the provisions of his first patent, further solidifying what has become a standard in the metal construction industry. RF