■ By Sharon Thatcher

Gutter protection manufacturer recognized potential, then pursued with persistence

Say what you will about having your mind in the gutter, but for the Ealer family, it’s been a pretty good place to be. From seamless gutters to gutter protection, their business, Midwest Enterprises, headquartered at St. Clair, Missouri, has helped to define two unique niches in the roll-forming market.

Jim Ealer Sr. was one of the first to identify the potential market for both: first seamless gutters then gutter screens and covers. According to his son, Jim Jr., his father was working for someone else in the 1960s when he was introduced to portable roll formers. “He worked on one of the early portable roll formers that did gutters,” he said.

Jim Sr. purchased his own seamless gutter machine and went into business on his own, with Jim Jr. joining the family business in 1976. “We made everything in-house,” Jim Jr. said, “the gutters, the downspouts, everything except for nails and screws.”

They purchased their aluminum straight from the mill, which was unheard for contractors at the time.

They had a major business. “We were doing the big orders of all the new housing starts in the metropolitan St. Louis area,” Jim Jr. said. “We pretty much had the new construction business sewed up.”

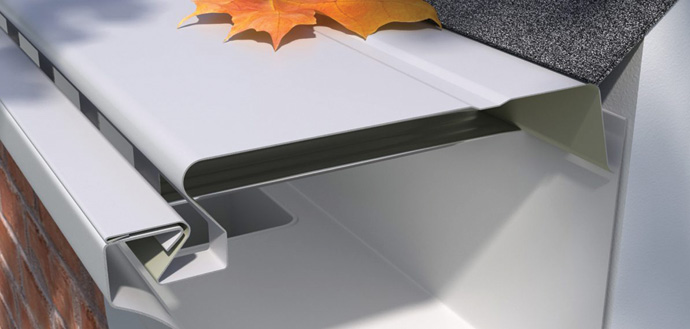

The popularity of seamless gutters was on the rise and so too were ways to keep them clean. There weren’t many options for the latter.

“In our installation, we couldn’t find anything that was very good,” Jim Jr. said. Being mechanically inclined, Jim Sr. set out to develop his own gutter protection solutions.

“He started experimenting and talking to roll-forming machine manufacturers about getting something made,” Jim Jr. said, “and they told him he couldn’t do that.” For Jim Sr. that wasn’t an answer, it was a challenge.

“He bought an old worn-out Lockformer machine [designed to make sheet metal ductwork] and started tinkering with it,” according to Jim Jr. “He knew a machinist who worked in St. Louis during the day but had his own machine shop where he worked in the evenings. The machinist would cut some wheels at night for my dad and all the next day Dad would tinker with it. That night he’d take the roll back and say, ‘OK, it has to be more like this; a little less here and a little more there.’ And he did that for like a year and a half before he could actually roll form a screen.”

The first product he created was the Easy Loc. “It was the very first screen that used spring tension to hold itself into the gutter,” Jim Jr. said. “It installed very quickly. It’s still on the market and still works great.”

For several years, the reformatted Lockformer was used exclusively for Ealer’s gutter installation business.

“He’d run it once in awhile and make enough material for our own use,” Jim Jr. said.

As other contractors saw the product, they expressed interest. Jim Sr. headed to nearby St. Louis to sell the product.

Organically the business grew into a regional, then a national business.

“He was selling in the Midwest, but then some of those people would get transferred to a different part of the country. They would call up and say, ‘We’re in Ohio now, can you ship it to us;’ ‘I’m in California now, can you ship it to us.’ It went on like that for 20 years or more, just word of mouth. We didn’t have a salesperson; my dad would just call someone once in awhile,” Jim Jr. said.

As the gutter screen business grew, the gutter installation business shrank due to competition, and around 1996 the Ealers left the installation business entirely.

“When we started doing seamless gutters in the 1970s, there was only like four seamless gutter trucks [in the St. Louis area]. By the time we got out of it, there was close to 400,” Jim Jr. said. “Eight of them were former employees. The problem: we’d train a guy for a couple years, and teach him everything there was to know and before you know it, he would go out and buy his own machine.”

While the gutter screen business was good, machine problems restrained Midwest Enterprises from major expansion for several years. It was still reliant on the worn-out Lockformer and other used soffit roll formers that had been bought and repurposed for screen and cover production. While Jim Sr. enjoyed the challenge of coaxing old machines into new life, they could be very unpredictable.

“We were making as much screen as we could manufacture. We didn’t really try to expand our business a lot because the machine was so inconsistent,” Jim Jr. said. “If you wanted to change over from 5″ gutter to 6″ gutter, it might take an hour, it might take two days, you never could say.”

Jim Jr. had left the business after the installation part of the family enterprise ended, but returned in 2004 to sell Midwest’s growing line of products. After about a year on the road, he was convinced there was a larger market in gutter protection still waiting to be tapped, if only they had more reliable roll formers.

“So I went out and found a roll-forming manufacturing company to make the machines we wanted,” he said. The source of those new roll formers remains proprietary.

By now, the company also had its own in-house powder coat line, not unexpectedly created by Jim Sr. “We didn’t just have someone come in and install one,” his son said. “My father went out and did some research for a year or two, went to conventions and trade shows, and he ended up buying some components from different people and designing his own line. It took him a couple years to get it right, but it works good now. We have two powder coat lines and coat over 12 million screens a year.”

The Easy Loc has been joined by another two dozen screen and cover profiles, another reaction to Jim Jr.’s observation while doing sales calls. He explained: “Gutter installers will get stuck on a product. They don’t care about who manufactures it, it’s the product type they want.” Maybe it’s a mesh screen that snaps and locks into place; maybe it’s louvered; maybe it’s punched with uniform perforations; whatever has proven successful for them in the past is what they want to install.

Jim Sr. has always been eager to accommodate them. It is particularly attractive to Midwest’s distributors, who may have traditionally bought product from four or five different manufacturers, to give their buyers the options they want. Midwest has now created so many options that distributors only need to come to them. “What we did was consolidate so they can buy from us and get a bigger discount, better margins by buying in volume from one manufacturer,” Jim Jr. said.

The business started in two buildings—a plant and warehouse—and has grown into a complex incorporating about 11 buildings.

Jim Ealer Sr. is 80 years old now, but still active in the business. “If he wasn’t being quarantined with Mom, he’d be down there making a machine do something else. That’s what he likes to do, that and riding dirt bikes,” his son said.

Of his father’s success, the younger Ealer added, “He wasn’t any smarter than anybody else, he was just persistent.”

All in the Family

Working with family day-in and day-out poses unique challenges, but Jim Ealer Jr., who has worked inside the operation for 40+ years, shares one of the family rules that keeps them together:

“My dad is a very competitive person, and he’s raised all of us to be pretty competitive. That’s a good thing when we’re all pulling together, but when you’re all pulling apart it’s harder to do. It’s gotten big enough now where we all have our different jobs. One of our rules is: If you get upset, you can say anything you want to, and you can walk out if you want to, but the work still has to be done, and as long as you come back the next day, everything is OK.”

Insights on Roll Forming

Midwest Enterprises has about 25 different roll formers in their operation, each machine dedicated to a different line. The company runs through about 45,000 tons of coil stock every three weeks in peak times of the year. Jim Ealer Jr. had the following insights about roll forming in general:

• “The hardest part of roll forming is getting the consistency. It’s buying good machinery, setting it up specially for the profiles we need, and getting all the extras set up: the guides, the punches, everything else to make a high-speed line.”

• “Each [aluminum] ingot is different; it depends on the type of recycled aluminum that goes into it. The mill can tell you in a range, and in that range it’s going to run different qualities. Sometimes it will twist like crazy and sometimes it will droop like crazy. We have one guy, all he does is adjust machinery to account for that. He specializes in that. He’s a very important piece of the aluminum department.”

• “Roll forming is very very frustrating. You can have the same exact coil and you can put it in the roll former 10 times and 8 times it will come out just the way you want it. But the other 2 times you’re going to have crazies. The adjustment of the roll former isn’t always consistent. You think, if I do this, it will do that. But sometimes you do that and it does something completely different. It has a mind of its own.”

• “There’s so much accurate tolerances—the gaps in your roll former — for the material to go through there and it all has to be level, no matter what type of roll former you use, it’s always going to be some kind of problem that takes trial-and-error adjustments. And whether the company that manufactures that comes in and does the adjustment or you have someone in-house, there’s always going to be some kind of bump in the road. You’ve got to be patient and persistent to get a consistent running line.”

For more information on the products and the company visit e-zgutter.com. RF

Originally published as “Midwest Enterprises” Summer 2020 issue Rollforming Magazine.