■ By Sharon Thatcher

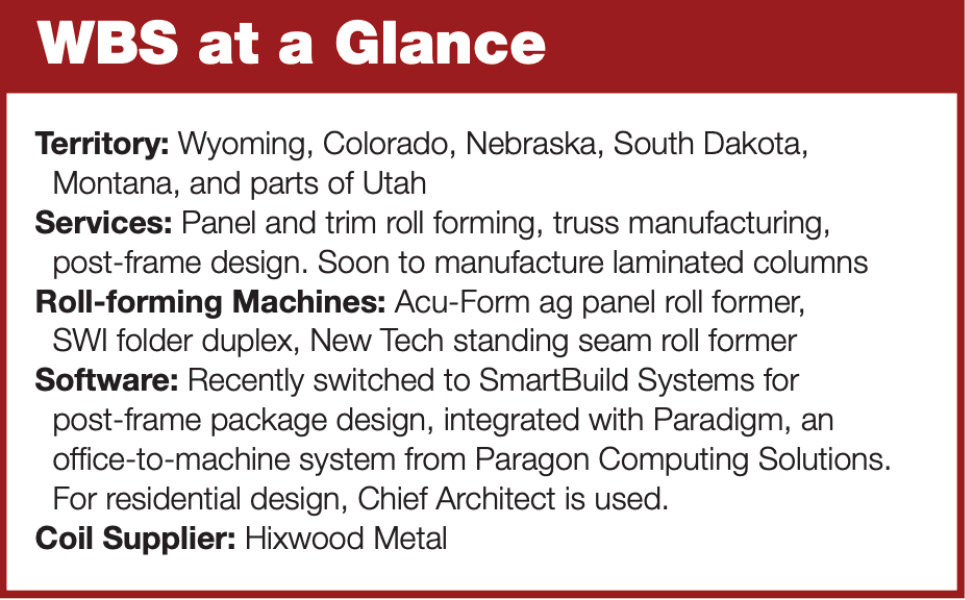

Have you ever thought, “Now there’s a good idea; I should do something with that”? The Hilty family of Wheatland, Wyoming, has had those thoughts many times, and by acting on them, it’s led to a series of successful enterprises that continues to expand a building supply business. Western Building Supply LLC (WBS) is owned by brothers Robert and Bruce Hilty. Not only a third-party supplier, WBS is increasingly becoming an onsite manufacturer of metal panels, trims, trusses, and more.

Although WBS is only eight years old, its extended history begins a couple decades and more than 1,700 miles away in Virginia. There, Robert’s and Bruce’s father was in the construction business and bringing three sons along for the ride. “We were the kids out there in the summer working construction rather than swimming,” Robert said.

“We were doing a lot of post frame,” he added. “We were also doing a lot of cement work, dirt work, roofing, homes from the ground up, remodeling, additions. Things that people wouldn’t or couldn’t do, or said it couldn’t be done, was sort of my dad’s forte.”

Their construction business began to evolve while in Virginia. Post-frame trusses were the first to come along, the motivation for the Hilty family to create its own truss shop coming when they couldn’t find the quality or timelines they needed elsewhere. When the family moved to Wyoming in 2011, the truss shop went with them.

At first, the truss shop was just supplemental income for an equipment rental store the elder Hilty started. The rental store was a success but so was the truss business. “He kept building trusses and then started selling lumber and metal roofing and siding, just buying wholesale, putting together packages and selling it,” Robert explained.

Robert and Bruce eventually bought the supply side of the business, along with a third brother who has since divested of his interest and returned to Virginia. Robert and Bruce added roll forming to the mix.

“A lot of where we are evolved out of needs that were presented to us,” Robert said. “Obviously we did some pre-emptively to create a demand, but the roll forming came out of: hey, we’re doing a lot of metal, I think it makes sense to put in a roll former.”

Their experiences sourcing metal during their contracting days helped to shape their business. While working with a larger supplier back in Virginia, the quality of panels was good, but panels too often came with forklift damage forcing replacement. “They would always replace it with no problem … but it was always a week, week-and-a-half before we got replacements,” he said.

They also tried a small regional roll-forming shop with mixed results. The quality was not consistent, “but the up side was that we could literally walk in there and in 20 minutes have a piece made,” Robert explained, noting that “it quickly opened our eyes to the advantages of a regional roll former, but also the perils of not handling things well and what that can do to a reputation. In small towns it doesn’t take long if you’re doing something badly to quickly have people distancing from you.”

When it came time to consider becoming a regional roll former the Hiltys vowed to offer quickness but not at the expense of quality. “It was like: you know what, we can do it better. We see the advantages of a regional roll former, we also see the advantages of a bigger company with better quality control, but we also see the disadvantages of both.”

Growing into their business

The Hiltys have always taken a cautionary approach to growth, using one success to bootstrap subsequent additions. For instance, they didn’t end the contracting side of business until they had gotten a good foothold in the building supply business. They didn’t add roll forming until after the supply business was well established.

When they did start roll forming, they chose to purchase a used machine, relying on Robert’s experience as a mechanic to keep it running. In hindsight, that had good and bad consequences.

“Looking back on it, from a financial standpoint we would have done better buying new,” Robert said. “We put a lot of time into repair and maintenance for the old one.

“On the flip side,” he added, “I learned a lot about roll formers and what makes them tick, and that’s something you can’t put a number on. It really helped me understand the process and the problems. When things arise, I can say: you know what, this is the problem, or this is what I think we should go look at.”

When their used machine exceeded its limits to handle all the work coming in, WBS added a new Acu-Form Equipment ag panel machine. It has been in operation for the past four years. Now they take every opportunity to upgrade equipment when possible.

“We take a very lean approach to our facility and our sales and manufacturing,” Robert said. “Productivity and efficiency are important to us, so we have a tendency to keep upgrading equipment as much as we can afford to keep that efficiency and that quality high. Often, when we have a need for more capacity, instead of adding people we’ll add equipment.”

Sourcing Steel

Sourcing steel coil for the roll-forming business involved a learning curve for the Hiltys. Wyoming is not located in a mainstream area, in fact it’s the least populous state in the nation and the second most-sparsely populated state, so there were delays in delivery from the national supplier they used. “You had to order by Tuesday to get it the next Tuesday, and if you missed that date—say you ordered on Wednesday—you were 13 days out on getting that product,” Robert recalled. “And when you’re a contractor trying to finish a job, that just doesn’t work well. It’s not a perfect world, things happen—someone miss-cuts a piece of metal, someone kinks a rib, someone drives over a package of metal—that is partly what drove us to where we are today and why we take the approach to some things that we do.”

WBS now buys coil exclusively from a regional supplier, Hixwood Metal out of Wisconsin. “They’ve been an absolutely excellent partner with us,” Robert said. “I can honestly say we would not be where we are without them.”

Finding Their Niche

The type of customer WBS caters to falls primarily into two main groups: the do-it-yourself rancher, and contractors catering to the region’s newcomers. Robert explained, “We brand ourselves as a pro store, but we serve a lot of the homeowners that come in. Our area is very much an ag/rancher area so by default they’re very much do-it-yourself. Our ranchers are just not going to hire somebody to do every whip-stitch thing, it’s just not how it works here.”

On the pro side, Wyoming is a state experiencing growth from the outside in, and some of those transplants are bringing money to spend. “I don’t have a percentage, but I’ll say 50% of what we supply are probably people moving into this area,” Robert said. WBS supplies the contractors who are building their new shops, sheds, and garages.

“Since we have small space, we specialize in the higher-end products, the oddball, hard-to-get things, that’s what we cater towards,” he went on to say.

Serving Both DIY’ers and Contractors a Tricky Business

Serving do-it-yourselfers and also serving contractors can prove tricky. Robert said the company’s philosophy is to steer do-it-yourselfers towards contractors when possible. “We have to be able to protect our contractors,” he said. “One thing we’re careful about, if someone wants to have a barn built, and they’re going to have somebody build it, but they want a price for materials first, we try to steer them back to a contractor and let the contractor come to us rather than give that person a price … we really do try to cater to our contractors and treat them well.”

Regardless of the customer, WBS aims to help people through their projects and problems. Noted Robert: “It’s very common for a contractor to sit down with us and we talk through a problem or process … We understand how it is when you get to the field and you miss-cut a piece, or you damage a piece, or you’re short a piece, or the wind picks up a piece and throws it across the field and ruins it. We know how important it is to get that piece back quickly so you can finish your job, get it dried in, get paid out, and move on.” RF

Stocking Inventory: It started with just one coil of burnished slate

Keeping lots of inventory is an expensive problem for roll formers. “It always seems like, when you’re running out of a color, that’s the one everybody wants … You wish you could just say ‘send me 20 trucks,’ but that’s hard to do,” Robert said.

When first starting out in roll forming, the Hiltys used their bootstrap philosophy to build their coil inventory. One of their first jobs called for an expensive coil in burnished slate. The Hiltys bought a roll, completed the job, and took the profits from the first roll of coil to purchase a second roll of burnished slate, “then we pushed burnished slate really hard,” Robert said. “I think we did that basically three different times. Our first three coils were burnished slate, one coil at a time, and we took the profits out of that and then bought the next color coil. That’s kind of how we’ve grown.”

WBS now stocks 31 different colors in mostly 29 and 26 gauge … and it all started with just one coil of burnished slate.

In the Future for WBS: Manufacturing the Complete Post-Frame Package

Western Building Supply has a long history with post-frame construction and owners Robert and Bruce Hilty have made post-frame a priority in their building supply business. Once serving as third-party suppliers for many of the main post-frame building elements, the brothers are doing more and more of the manufacturing in house: from truss building, to roll-forming metal panels and trim, and now, laminated column production.

“What we’ve done is looked at the industry and identified the parts that cause the most pain; that’s roll forming, that’s truss building, and that’s laminated columns,” Robert Hilty said.

Truss manufacturing is being expanded to enable 105′ to 110′ post-frame spans. A laminated column machine has been purchased and is being put to work.

“We’ve really taken the pieces of the pole barn and post-frame industry that are kind of cumbersome and that are difficult to get done quickly or to fix if something goes wrong,” Robert added. “The goal is to expand into a fairly regionally-known manufacturing supply facility.”

Originally published as “When Do-It-Yourself Turns Into a Business” Winter 2020 Rollforming Magazine.