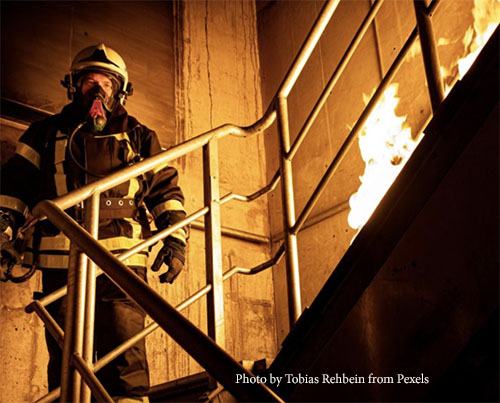

Construction metal forming requires delicacy, concentration, and a positive, undeviating attitude toward safety. With large machinery, sharp tools, and high temperatures, wearing protective clothes is important for your well-being.

A well-chosen outfit will protect you and enhance your work productivity. This guide examines safe workwear basics, special considerations for metal forming, and how to care for your gear.

Key Features of Safe Workwear

Proper workwear is the first line of defense in construction metal-forming. Selecting attire with the right features not only ensures your safety but also enhances your efficiency on the job. The following are some critical characteristics to consider when choosing protective clothing:

Durable and Flame-Resistant Materials

The main fabrics used to manufacture FR fabrics, such as treated cotton or Nomex, help protect workers from sparks and high temperatures frequently occurring during metal-forming. Clothing rated under NFPA 2112 or ASTM F1506 should be considered.

Secure and Non-Loose Fit

Loose clothes are likely to get caught in the machines, posing critical hazards. It is better to wear close-fitting coveralls or work shirts with minimal loose clothes.

Reinforced Protection Areas

Work pants with extra padding or reinforcement increases durability and protection in high-wear areas like knees and elbows. These features reduce the risk of cuts or punctures when handling sharp metal edges.

Visibility Enhancements

High-visibility workwear with reflective strips is essential in low-light conditions or when working near moving equipment. ANSI/ISEA-certified hi-vis gear is the industrial standard of choice.

Breathability for Comfort

Breathability is important to avoid overheating in extreme physical operations. Advanced moisture-wicking materials will keep workers cool and comfortable throughout the day.

Safety Gear That Goes Beyond Clothing

Workwear is only part of the solution—pair it with the right safety gear for complete protection:

Protective Footwear

Steel-toe boots or shoes with puncture-resistant soles protect against heavy falling objects and sharp debris. Ensure they are compliant with ASTM F2413 standards.

Eye and Face Protection

Most operations related to metal forming produce particles that could cause an eye injury through flying particles or hot sparks. ANSI Z87.1-rated goggles or face shields are imperative in protecting the eyes from such injuries.

Precision Gloves

Cut-resistant gloves, such as those made of Kevlar material, ensure dexterity and safety when handling sharp objects. Avoid gloves that are too bulky because they reduce one’s precision.

Hearing Protection

Noise levels in a metal-forming environment can reach hazardous levels. It is essential to utilize the right hearing protection, such as earplugs or earmuffs according to OSHA standards on noise reduction.

Respiratory Protection

Noxious fumes and dust can lead to serious respiratory problems. Wearing an approved respirator by NIOSH has assured safe breathing conditions.

Special Consideration for Metal Forming

Because of the nature of metal forming, there are special safety concerns that are mitigated by particular choices of workwear:

Heat Resistance during Welding and Cutting Jobs

Flame-resistant welding jackets and aprons will be useful for jobs with high heat. Most are made of leather, which is strong and tolerant of high temperatures.

Avoidance of Synthetic Materials

Synthetic fibers, like polyester and nylon, may melt when exposed to heat, increasing burn risks. Choose natural fibers or synthetic blends that are FR-rated.

Chemical-Resistant Materials

Some metal-forming procedures require exposure to chemicals or lubricants. Wear workwear with chemical-resistant coatings for skin protection.

Arc Flash Protection

Arc flash-rated clothing is necessary for any workers exposed to electrical hazards. Make sure gear meets relevant safety standards, such as NFPA 70E.

Workwear Maintenance and Inspection

Proper care prolongs the life of safety gear and maintains protection. It includes:

Regular Inspections

Inspect workwear for wear and tear or compromised protective features. Immediately replace damaged gear to avoid accidents and fatalities.

Proper Cleaning

Follow the manufacturer’s cleaning guidelines, especially FR garments, to protect their fire-resistant properties. Avoid using bleach or fabric softener, as these degrade the fire-resistant fabric coatings.

Storage Best Practices

Workwear should be kept dry and clean, away from chemicals and exposure to sunlight to avoid degradation.

Replace in Time

The toughest workwear has a limited life. Replace gear that has exceeded its recommended service life or shows significant wear.

Why Safe Workwear is Non Negotiable

Workplace injuries in the metal-forming sector have substantial financial and physical impacts. OSHA reports that poor use of safety equipment or insufficient protective apparel leads to thousands of injuries in construction-related industries.

Businesses may lower these risks and employees can concentrate on productivity without sacrificing safety by investing in high-quality workwear and maintaining it properly. RF

Nick Warrick is the Sales Manager at All Seasons Uniforms. With over 15 years of experience in the work uniform business, he has worked with hundreds of clients across 20 different industries.