By The Metal Construction Association

Overview:

One of the most enlightening comments made regarding custom color samples was from a paint supplier who, when asked to supply a sample of a white finish, said: “You don’t understand, there are over 200 shades of paint that are referred to as ‘white’.” Custom color is commonplace in today’s construction and coil coated metal is no different than many other materials. No matter how many versions of a color are available, the designer is searching for something unique and different.

The difficulty is what the architect or designer wants to review is often outside the ability of the coil coated material suppliers to provide.

Discussion:

Visual appearance of the final, installed product is critical to the successful completion of the project and enabling the architect to make color decisions is critical. One very important tool to make that important decision is the color sample. The typical specification will have a requirement for the color sample to be in the range of 12” x 12”. When calling for a standard color, this size request is generally reasonable since the sheet manufacturer often has standard colored coil available, however, it is generally not possible to create a custom color sample (on metal) of this size.

To create a custom color sample, three key elements are required: paint formulation, paint application thickness, and curing of the painted surface.

Paint Formulation: It is very common for a paint company to create several different options to meet the final appearance desired by the designer. In general, there are solid, mica or metallic colors available to the designer. The paint is a formulation of binders, pigments, additives and solvents that may require as many as three different layers to get the precise color and gloss level desired. It is a good recommendation to provide a paint chip or sample to match a custom color otherwise it is a guessing game to determine the look required.

Paint Application Thickness: Due to cost and equipment limitations, most paint samples are not created on the actual production paint line. These samples are often created in a paint manufacturer’s laboratory by hand with special tools used to obtain the desired paint thickness (and therefore the correct color and appearance). Layer thickness is critical to color development and visual appearance. Nearly all of the metal coil coated paint performance characteristics are defined in either AAMA 2605 or AAMA 2604 (depending on the finish type) and are impacted, in one way or another, by finish layer thicknesses.

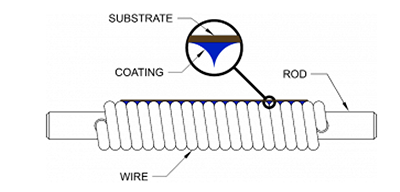

In preparation of a color sample, the various layers are typically applied using drawdown rods (a.k.a. Mayer Bars).

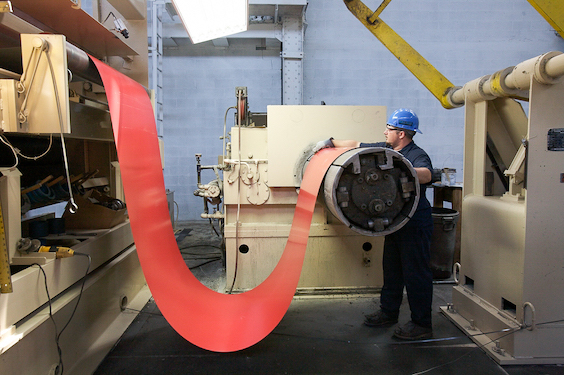

The drawdown rod is manufactured using a steel shaft wrapped with a specific gauge of wire as shown above. The wire diameter controls the film thickness when the rod is pulled across the metal substrate. This is a manual operation and the best way to control finish thickness which in turn affects the visual appearance. Note the “V” shape area that is filled with paint when the rod is pulled along the metal. While this “V” shape will subside somewhat, this is the cause of the drawdown lines often seen on paint samples. While not perfect, samples with “drawbar lines” are considered the standard for coil coated custom paint samples used to judge the overall appearance of a finished project.

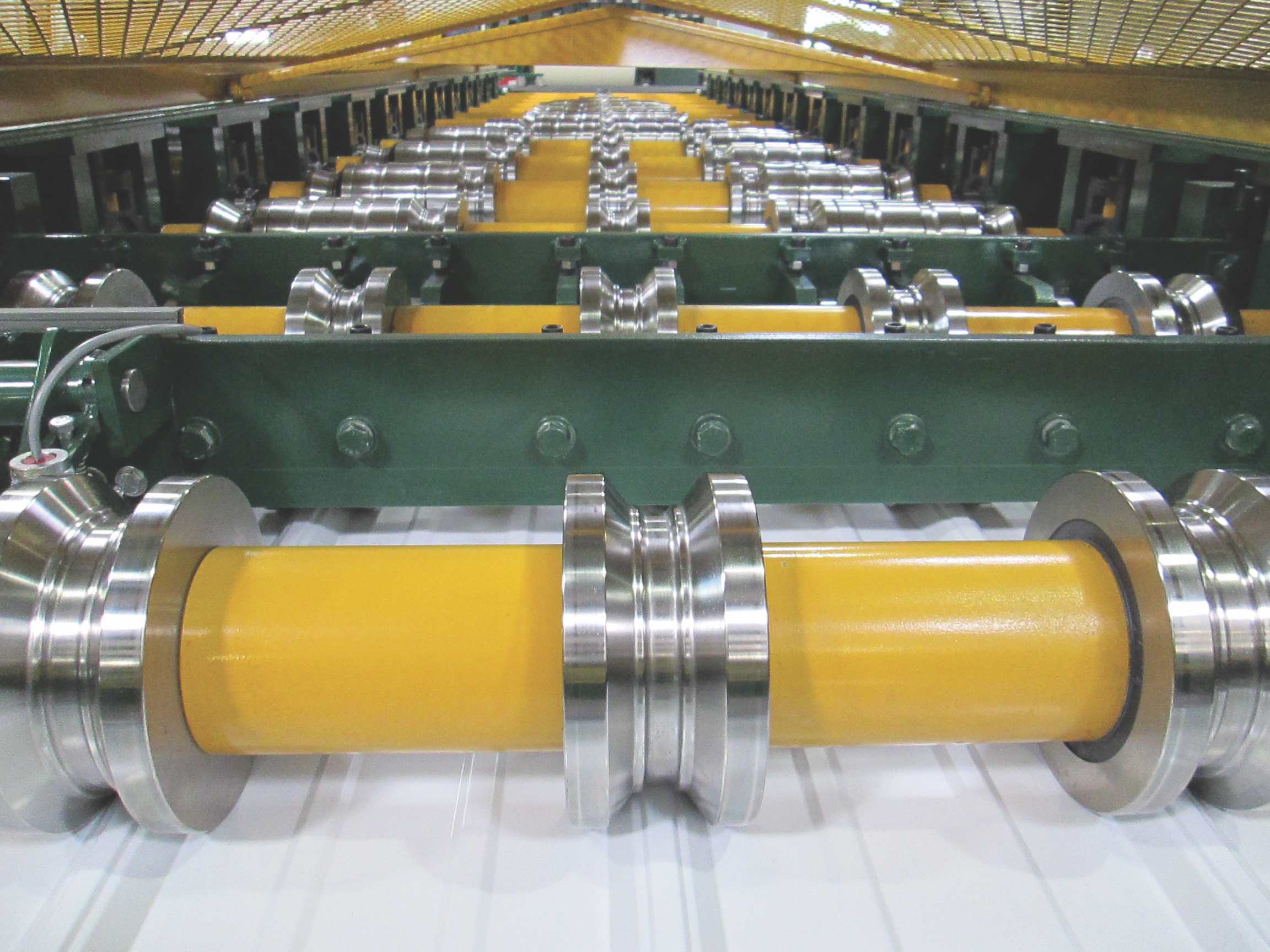

The actual finish is applied by a smooth roller for coil coated metal so drawbar lines are not created anywhere in the coating process.

Curing of the Painted Sample

After each layer of the finish is applied, the coil sample is inserted into a custom lab oven to cure the paint layer. This oven is precisely controlled in temperature and duration to cure the paint and provide the appearance and paint performance that will be seen in the finished coil. Not only is the ability to apply the coating evenly (using the drawdown rods) critical, but the size of the oven to cure the sample is also often very limited.

Obviously, the larger the coil sample, the more difficult it is to ensure that the entire surface experiences the same temperature for the proper amount of time. For these reasons, the maximum size of a custom color sample is often limited to about 3” x 4”. While not ideal as a visual sample it does provide a realistic color sample showing the general color appearance expected in the finished product.

Summary:

While not an exact duplication of the true coil coating process, the custom color sample production process does provide a representative sample of the finished color appearance. The actual paint application is often accomplished using a reverse roll-coating process and does not include any draw down lines that may be shown in the custom sample, however this is the best technology available to create accurate thickness layers of finish. RF

Founded in 1983, the Metal Construction Association brings together the diverse metal construction industry for the purpose of expanding the use of all metals used in construction. For more information, visit the MCA web site at www.metalconstruction.org