By Karen Knapstein

If you don’t know what to ask for, odds are you won’t get what you need. Asking the right questions is the first step in getting the coil you need to fill your customers’ orders to their satisfaction. Coil width and thickness are two of the most obvious factors that affect metal forming. They influence the quality of the final product, the performance of the machine, and the amount of sale-able material you can get out of a coil. 3GM Territory Manager Adam Buck, who has 15 years of experience in metal roofing manufacturing and sales, shares his insights about metal coil size and thickness.

Coil Width

Adam explains the standard coil widths for different gauges: “The industry standard width for 29 ga. coil is 40.875”. Some people will order that material in 41” because they want to make the underlap and overlap on their metal panel a little bit wider.” However, he estimates more than 99% of what people use to make 29 ga. ag panel and residential panel is 40.875” wide.

The thicker 26 ga. material, commonly used to make R panel or PBR panel, comes in 41.5625” and 43”-wide coil.

Users should be cautioned: The wider material won’t fit through all machines. The width tolerance is the difference between the lower and upper limit dimensions that a roll former will accept. The guides in the roll forming machine will determine that tolerance.

“A lot of people want an ag panel rib height of 7/8” but want it in 26 ga. but they don’t want to pay a processing company to slice the material down,” Adam explains. “So they often ask if the 26 ga. material will run through an ag panel line. The answer to that is ‘Some do, some don’t.’ It depends on the guides in the machine.” Roll formers need to measure the guides to see if the larger coil will work in their machine.

You can count on the consistency of the coil width if you buy from a reputable supplier. Adam says if you order a coil 40 7/8” wide, it will be 40 7/8” wide — but there could be a very small variation (+/- 1/16”). If it does vary a little bit, you may have to adjust the guides on your machine to make sure their overlap stays long enough for the panel to lap properly. “You can’t really steal from the overlap side of the panel; you must steal from the underlap side when you’re adjusting your machine,” he continues. “There’s very little extra material to play with.”

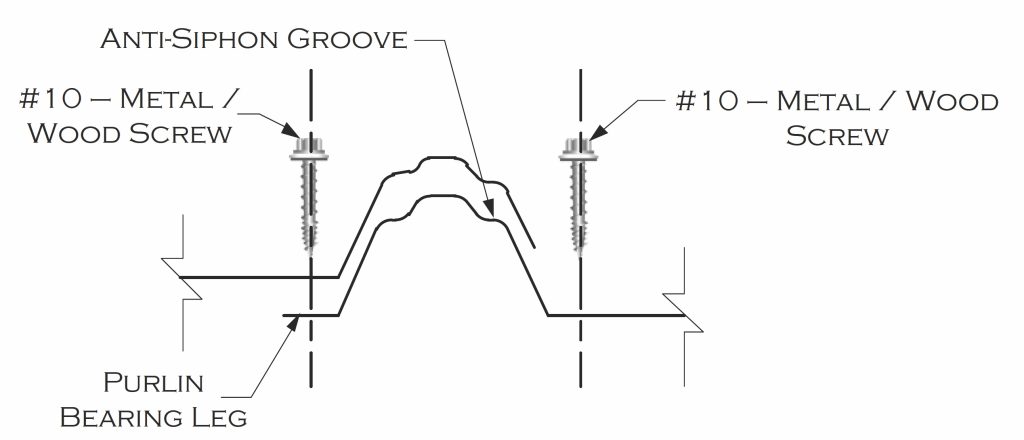

If the coil is narrow, a small amount can be “borrowed” from the underlap side but enough must remain to attach to the purlin because it gives the panel its rigidity. Photo courtesy of 3GM Steel.

Coil Thickness

When addressing coil thickness, the main thing Adam stresses is the yield — the weight per linear foot (pounds/foot). The pounds per foot is the weight of 1’ of a specific width of coil (i.e. 40.875” x 1’). “A lot of people in the industry get caught up in the decimal thickness,” he explains. “The common thicknesses in the industry are .0138”, .0142”, .0145”, .0150”, .0153”, .0157”, and .0185”. Thicknesses from .0138 to .0153 material are all 29 ga. product. On the steel service center side of things, when you’re purchasing coil from mills you’re buying by the pound. Our customers are typically buying it by the foot.”

He gives one example of why the reason yield matters so much: “I was at customer’s place and he had some .0153 material on his floor. If I order that thickness I would expect to get a target yield of about 2.04 pounds/foot. I checked all the coil tags, and what I found is the coils weighed anywhere from 1.92 pounds/foot to 2.05 pounds/foot. What that shows is just because a coil tag says .0153 thickness it doesn’t mean the yield corresponds with the thickness of the material. If the coil tag says it’s .0153 thickness and it weighs 1.92 pounds/foot, it’s actually not .0153 thickness. The yield is what tells me what the thickness is.”

“Tell me what you want it to weigh per foot and that’s what I’ll make sure it weighs,” he continues.

3GM supplies roll formers with a lot of 29 ga. coil. “When I’m qualifying a customer, the customer usually says they’re looking for 29 ga. .0153” material. My next question is: What do you want that to weight per foot? The customers don’t request a yield, but in the backs of their minds they have a yield that they’re trying to hit. But they never communicate that unless they’re asked.”

Gauge is a guide — not a hard and fast measure. “If the customer wants material that’s 2.02 pounds/ foot and I send him 1.92 pounds/foot, he’s not actually getting the material that he wants because he’s not going to hit the yield that he has in mind,” explains Adam. “A lot of people get caught up on decimal thickness. For me, as a coil supplier, the decimal thickness is a guide but it doesn’t really mean a whole lot. I like to get down to the specifics: the yield and what it weighs per foot. So if I know a guy is looking for 2.04 pounds/foot, I know what yield they’re looking for specifically.”

Adam continues: “With most mills, if you order .0153” thickness, for the most part it’s going to be a heavier 29 ga. product, say 2.04-2.05 pounds/foot. But I’ve seen on occasions where it’s definitely not, like the example I gave earlier.”

Minimal & Nominal Thicknesses

Understanding thickness terminology will help you get the material that will give you the yields you need. “Minimal thickness” is thickness that will be greater than or equal to the target thickness. “Nominal thickness” can be equal to, thicker or thinner than the target thickness. For example, when you ask for .0150” minimal thickness, the coil will always be at least .0150”. If you ask for .0150” nominal thickness, it may measure anywhere from .0147” to .0153” from coil to coil. Nominal thickness is thickness that can vary the most; it may be plus, minus or equal to the target thickness.

“The industry as a whole typically goes with minimal thickness,” Adam says, “but you do see a little bit of nominal thickness out in the market. Minimal definitely provides a more consistent product.”

The consistency of the thickness can vary from mill to mill. “Mills have their own quirks, and some mills have it dialed in better than others,” he says. “Some mills you see a lot of variance.

We try to stick with mills that really dial in their product. We don’t want to see a whole lot of switching back and forth between thicknesses when we’re sending customers product. We want to provide a great quality product that’s very, very consistent. Whether they’re buying it today or buying it six months from now, it should be about the same.”

Problems and Mitigation

There are a few tips and tricks to mitigate coil and width variances. Regarding thickness variances, he advises that when switching coils, if going from .0138” material to .0153”, you may have to back the guides off by a thousandth. Or vice versa, you might have to tighten it down a thousandth if you’re running it a little bit thinner.

“If the material is too thick and you roll form it without adjusting your machine, you could scar your panel and/or peel the paint off the material. As the material goes thicker, you have to back off the dies in order to produce a thicker product.”

Dealing with width variance can be a bit more tricky. For example, say a customer orders 40 7/8”, he roll forms the product and the overlap isn’t long enough. That means the coil isn’t wide enough. So he has to “borrow” material from the underlap side to put on the overlap side. “He might not have enough underlap left,” explains Adam. “That material is going to be tough to use. You can use it for trim or you can try to find a happy medium and use a very small underlap. The underlap is so important because that’s a purlin-bearing leg — it adds strength and rigidity to the panel. If both sides were overlaps, it would be a really flimsy product regardless of the gauge. Rigidity is important.”

Adam assures that roll formers usually have very few problems with thickness and width. “Most of the steel mills — internationally and domestically — have it dialed in pretty good in a construction product they know what needs to get into customers’ hands to roll form a great product.”

Keep Accurate Records

Buying quality coil is a critical step in running a profitable roll forming business. When something goes wrong, it can jeopardize your profitability. Keeping accurate records is cheap insurance in protecting that profitability. The importance of keeping accurate records can’t be overstated. If one of your customers comes back with a complaint, you need to be able to tell your supplier specific details about the materials. “The first question we ask on the service side is what coil tag or coil number it came off of,” Adam explains. No matter who your service center/supplier is, they will ask for this information. They can’t make any an assumption about which coil is the problem; they have to provide the mill with specific, factual information in order to process a claim. Adam says once they have the specific information, then they can go back and look at the mill certifications and quality control reports released by the mills in order to track warranty claims.

Conclusion

Clear communication with your coil supplier is important. When you process coil into panels and trims, you need to know the profit margin on each coil. If the material you are using isn’t sellable/usable, your profits won’t end up where you need them to be. RF

About 3GM Steel

3GM Steel is a family-owned and operated American steel trading and coil distribution sales company, specializing in pre-painted Galvalume®, pre-painted Galvanized and bare Galvanized and Galvalume® materials. The company enjoys a reputation for providing the highest quality product available, at competitive prices, delivered with professional service. 3GM Steel maintains strong relationships with tier one, high quality steel suppliers and has been importing and distributing pre-painted and coated coil products from a number of top-class domestic USA and Asian mill sources for 20 years. The company’s purchasing, sales, and support staff combine over 100 years of steel mill, import/export trading, roll-forming, and flat-rolled sales experience. This extensive and diverse mill and painted coil industry experience, along with regular visits to supplier facilities, provide a unique perspective to understanding and communicating the nuances of customers’ requirements to mill staff, helping to ensure order accuracy and efficient delivery.