By Eric Lundin, T&H Lamont

Equipment maintenance isn’t always at the forefront of a manufacturing company’s plans, budget, or Monday-morning huddle, but equipment maintenance is more than necessary. Of course, every dollar spent on maintenance has to be justified — maintenance is a cost, after all — but a well-planned, comprehensive maintenance program can pay for itself many times over. Keeping a close eye on the equipment’s condition, and taking steps to keep it in good shape, can help every manufacturer get the best return on its equipment investment by stretching the service life of every machine in its shop.

A small company might not have a dedicated maintenance department, so for some roll forming shops, developing a comprehensive maintenance program might sound like a daunting task. However, maintaining industrial equipment doesn’t have to be any more complicated than maintaining an automobile. And while this may be hard to believe, automobile maintenance actually consists of five separate but overlapping maintenance strategies.

Anyone who has ever owned an automobile can probably think of two right away: Changing the oil on a regular basis and checking the oil level between oil changes. Every automobile owner uses at least two more, and some use three more.

The Five Commonly Used Maintenance Strategies

The five maintenance strategies don’t have a specific order, but they have specific definitions, as follows:

Reactive: Run to failure

Corrective: Unscheduled repair

Predetermined:

Manufacturer’s schedule

Preventive: Modification to the manufacturer’s schedule

Condition-based:

Uses sensors and gauges

Using the automobile analogy, most people would never consider running it to failure. An automobile is simply too expensive and too necessary to neglect, so running to failure sounds extremely foolhardy. In reality, we do it all the time. Headlights are a good example. The slight inconvenience of one burned-out headlight, combined with the ease of replacement, outweighs the need to replace a headlight before it fails. The same goes for turn signal lamps, side markers, and so on.

Next is corrective maintenance. An automobile owner might pop the hood to check the oil and notice a frayed belt or an aging radiator hose.

Predetermined is the most familiar. Everyone knows that keeping the engine well-lubricated is a key to an automobile’s longevity, so sticking to the manufacturer’s maintenance schedule is critical. Of course, the same goes for everything else that requires any sort of lubricant.

Preventive maintenance takes predetermined maintenance one step further. When a vehicle used in heavy-duty service, such as towing or carrying substantial payloads often, it’s probably a good idea to change the lubricants more often than the manufacturer’s schedule stipulates. The same goes for driving in desert locations or semi-arid areas prone to wind-borne grit and dust. The air filter will become clogged much more quickly than when driving in other conditions, so more frequent replacements will keep the engine breathing easier.

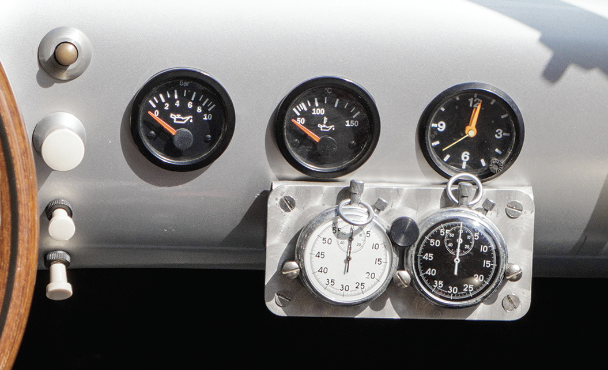

The final strategy — condition-based — relies on the automobile’s condition as picked up by sensors and displayed on gauges or meters on the dashboard. Like run to failure, the machine’s condition leaves no room for doubt. The other three, while necessary, are based in part on some guesswork. A fraying fan belt might last many more miles, and it’s hard to say if the manufacturer’s schedule for oil changes is ideal, or if it’s cautious, and the same goes for preventive maintenance. But condition-based maintenance is very specific.

In the case of an automobile, the radiator’s temperature gauge is a good example. If the radiator coolant temperature is lower than usual, it might indicate thermostat stuck open, not allowing the engine to get up to its normal operating temperature. Running too hot? The thermostat might be stuck closed, or the radiator coolant level might be too low, or the radiator passages might be clogged, or perhaps something far more expensive is the culprit, such as a leaking head gasket. In any case, the automobile owner knows for certain that something is amiss and it needs attention. Now.

Machinery Applications

Regarding industrial machinery, these strategies are essentially the same.

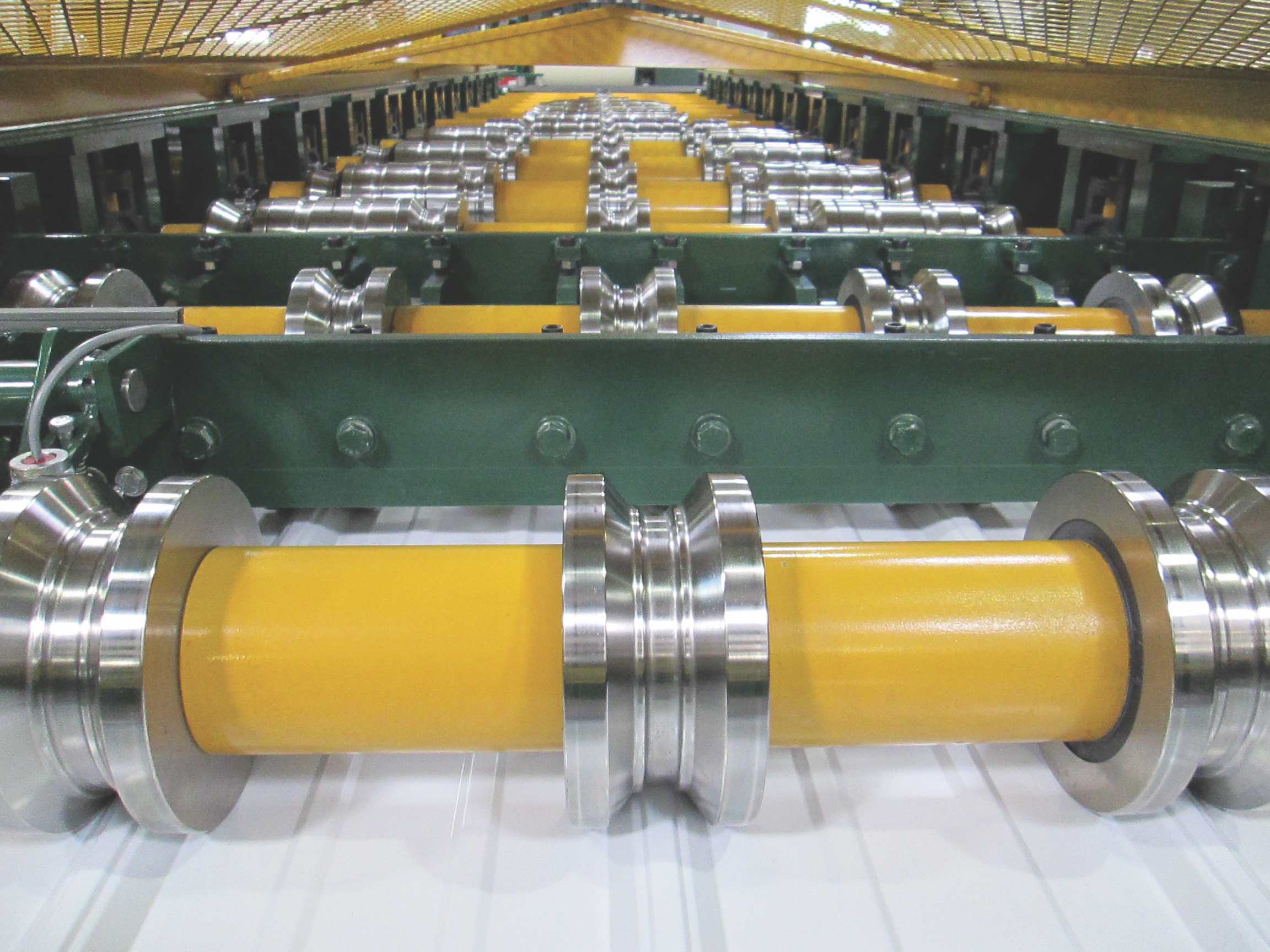

The basis for maintenance is the predetermined strategy based on the manufacturer’s schedule. These activities can be elaborate, intrusive actions, like shutting down the equipment annually and tearing into the machine to inspect the motors, gearboxes, and other drive-system components. Also, the manufacturer’s schedule includes frequent, less intrusive tasks. These usually are daily, weekly, and monthly, and involve visual inspections to look for loose hardware, loose chains, worn belts, aging hydraulic hoses, and so on. These inspections can lead to repairs, which would be corrective maintenance.

A preventive strategy could apply to any machine, component, or tooling run close to its maximum intended capacity or maximum production rate, or both. The manufacturer’s maintenance schedule is likely intended for average conditions, or varying conditions, so running the machinery full-tilt all the time is probably beyond the manufacturer’s expectations for wear and tear, and preventive maintenance is in order.

A reactive maintenance action is likely to come up once in a while, despite sticking to the maintenance schedule. A bearing might go bad prematurely, and while it might not necessarily fail entirely, it needs replacement if it fails to do its job.

Last is condition-based maintenance, which relies on the use of sensors and gauges. These aren’t as common in roll forming as they are in something like a chemical processing plant or a refinery, but putting more reliance on them could help rollformers spot a small problem before it becomes a big one.

A New Take on Condition-based Maintenance

In a technical article published in The Tube & Pipe Journal (and posted to www.thefabricator.com), author Paul Hogendoorn discussed condition-based maintenance. The goal of his article wasn’t actually related to maintenance, but it showed how a system monitor could be a substitute for quality control. In doing so, his article demonstrated the power of condition-based maintenance.

Hogendoorn’s idea is that monitoring the machine’s condition for process consistency is a good proxy for quality consistency. Titled “What Do You Monitor to Ensure Quality? Forget Parts — Focus on the Process,” the article discusses how this is done, its advantages, and its disadvantages.

The example in the article uses a strain gauge mounted to the frame of a machine or a component. The component, which could be a punching or shearing unit on a roll forming line, generates a force every time it cycles. The workpiece resists that force, and the result is a strain that can be measured directly by a strain gauge.

The Setup. A strain gauge uses a piezoelectric sensor, which generates a tiny amount of voltage when it’s under strain. As the punch or blade goes through a cycle, the strain changes in a very repeatable way. The tool enters the workpiece, parts it, and exits, creating a specific strain signature.

The voltage output is weak, so this sort of system requires hardware and software that work together to amplify and interpret the output.

The Thresholds. The output is based on several factors, including the raw material, lubrication, tooling condition, machine setup, machine condition. As long as all of these are consistent, the strain gauge’s output will be consistent. The machine’s output — a punched hole or a sheared end — likewise will be consistent.

Before starting a production run, the machine is optimized with a thorough inspection, including any necessary adjustments or repairs, and new tooling. By processing several samples of known good material, the strain gauge generates several outputs, which the software averages together to create a representative signature.

An experienced engineer can then set thresholds, or limits, for the maximum and minimum acceptable amount of strain. Any amount of strain recorded beyond the threshold triggers an audible or visual alarm, or both.

The Frequency. The beauty of this system is a twofold benefit. First, during a production run, the system runs in the background, requiring no attention from the operator. Second, it compares the reference strain signature to every cycle’s strain signature to interpret the stability of the process. In other words, it provides 100 percent coverage, monitoring every cycle during every production run, shift after shift, day after day.

The Trigger. A drawback to this system is that it’s not diagnostic. A trigger that sets off the alarm tells the operator that something has changed, but it doesn’t identify the cause. The blade or punch may be chipped, the lubricant reservoir may have run empty, a component somewhere inside the punching or cutting unit may have broken, and so on. This is the tradeoff. The system is comprehensive, catching any change to the process; but it’s not diagnostic.

Advantages and Disadvantages

On one hand, this system provides a reasonable substitute for a conventional quality control system. As long as the monitoring system doesn’t alarm, the operator has confidence that the process is stable and the part quality also is consistent. Also, it’s simple to use in that it requires no operator training. On the other hand, a conventional quality control system is time-consuming and labor-intensive, and usually requires operator training.

Both systems require an investment to get started, so this is a toss-up.

A disadvantage to relying on process consistency is that it can’t catch every sort of flaw that might occur in the production process. For example, it can miss flaws that are hidden in assemblies.

As far as the equipment maintenance side of the equation, the process monitor keeps costs under control. It reduces or eliminates the likelihood of performing machine maintenance too frequently, which increases downtime and wastes resources. It also reduces the likelihood of carrying out machine maintenance too late, which can allow a small, inexpensive problem to become a critical and expensive problem.

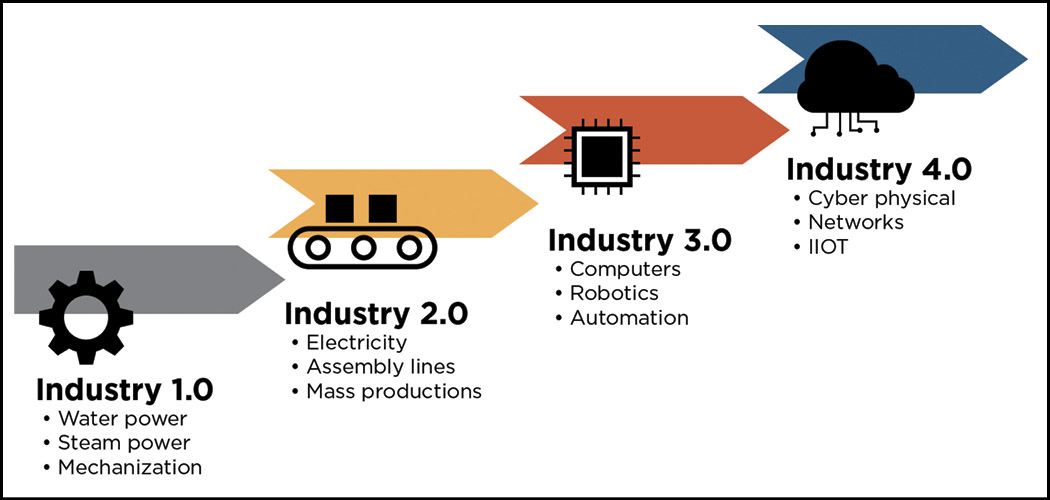

Today’s Version of Process Monitoring

The system Hogendoorn discussed in his article isn’t a do-it-yourself project; it requires hardware, a setup, and programming from a company that specializes in the sensor technology and the algorithms needed to compare the reference strain signature to the production strain signatures. However, small manufacturers with tight budgets have other options.

Although Hogendoorn’s article, and the system it describes, is just as valid today as it was when it came out a few years back, much has changed. The internet wasn’t as fully developed then as it is today. These days nearly everything and anything electronic can be connected by Wi-Fi or Bluetooth, so options abound. In other words, while Hogendoorn’s system is extremely capable and versatile, these days a maintenance department might be able to develop a more basic system without relying on experts to set up and program a system.

Sensors that can connect wirelessly are available to measure some of the critical aspects of industrial machinery, such as vibration and temperature, which would help to assess the condition of transmission components such as gearboxes. Sensors are available to measure the voltage, current draw, and torque of electric motors.

Setting up such sensors takes several steps, but it’s fairly straightforward. The first step is to set up a gateway that sends the data it gathers to the cloud. The second step is to connect the sensors to the gateway. After everything is up and running, the sensors operate in the background, gathering data and sending it to the cloud continuously.

And the people responsible for maintenance can rest a little easier. RF

Eric Lundin is a Sales Engineer at T&H Lemont. T&H Lemont is a custom manufacturer of machines, components, tooling, and consumables for producing tube, pipe, profile, and panel.