Your roll former only makes money when it’s up and running. Therefore, it’s critical to keep it operating properly and producing efficiently. Regular roll former maintenance will prevent long-term breakdown and expensive repair.

Develop a Preventative Maintenance Schedule

The way to ensure regular maintenance is to schedule it. Every roll former will come with a manual that outlines required maintenance. Review and understand the maintenance instructions provided in the equipment manual thoroughly. It’s vital to adhere to the recommended schedules for routine checks, inspections, and servicing outlined by the equipment manufacturer or supplier.

Lubrication Routine/Schedule

Identify critical components that require regular lubrication, including rollers, bearings, and chains. Details for maintaining a proper lubing schedule should be supplied or available from the manufacturer.

It’s important to use the specified lubricants and follow the recommended intervals for application. Like any and all maintenance, it’s a good idea to keep a log of your lubrication schedule.

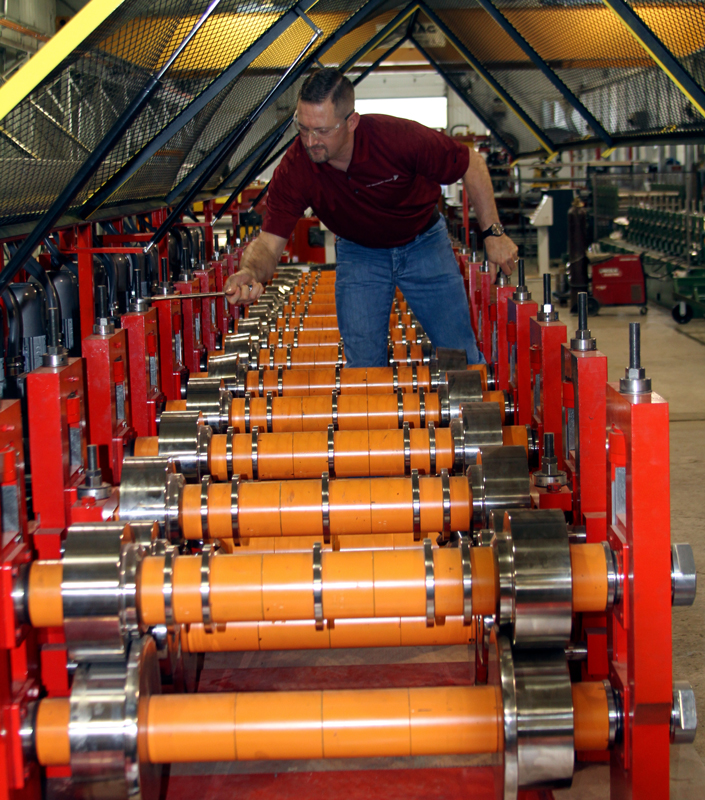

Inspect and calibrate machine’s tooling.

Photo courtesy of The Bradbury Group

Adjust the roll tooling.

Photo courtesy of The Bradbury Group

Inspect and Replace Tooling

Regularly inspect the tooling for signs of wear or damage — either could cause your roll former to produce pieces that are not consistent or meet the standards required by your customers. Replace worn-out tooling promptly to maintain the precision and quality of the forming process for the products being roll formed.

Align Critical Components

It’s imperative to perform alignment checks on tooling, tooling gap and other critical components according to the manufacturer’s specifications. You can utilize precision measuring tools to ensure accurate alignment. If and when you detect any misalignments, address them promptly to prevent issues like uneven profiles or production inconsistencies.

Keep Equipment Clean

Dirt and dust build up everywhere. Periodically, wipe down the stands and equipment to keep excessive debris from accumulating. This will aid in identifying issues with the equipment before a component fails and leads to a breakdown.

Safety and Training

You should provide comprehensive training to operators on safe equipment operation as well as maintenance procedures. You owe it to your operators to emphasize safety! Follow your schedule for regular safety checks, ensuring emergency stops, guards, and other safety features are functional. Always maintain detailed records of operator training and safety inspections.

The best way to get a return on your investment in a roll former is to keep it running consistently and safely. Follow your maintenance schedule and keep track of all maintenance.