Companies that produce metal roofing components can improve capacity and shorten lead times with no capital expense. Here’s how you can do it too!

You have positioned your roll formers, shears and folders/brakes and are satisfied that you are making money, but you would like to make more and to shorten the time you promise customers to deliver their orders. Not only will I show you how to reduce labor costs, but at the same time increase capacity and shorten lead times so you can gain more customers with competitive lead times.

This is so simple that it works!

Situation

I found that manufacturers of metal roofing panels and trim elements look for ways to shorten lead times to customers so they could be more competitive and earn more business. As an Industrial Engineer and Continuous Improvement leader for Procter & Gamble, Gillette, Amgen and other clients, I learned to optimize your current process first, before adding people or buying new equipment to build capacity.

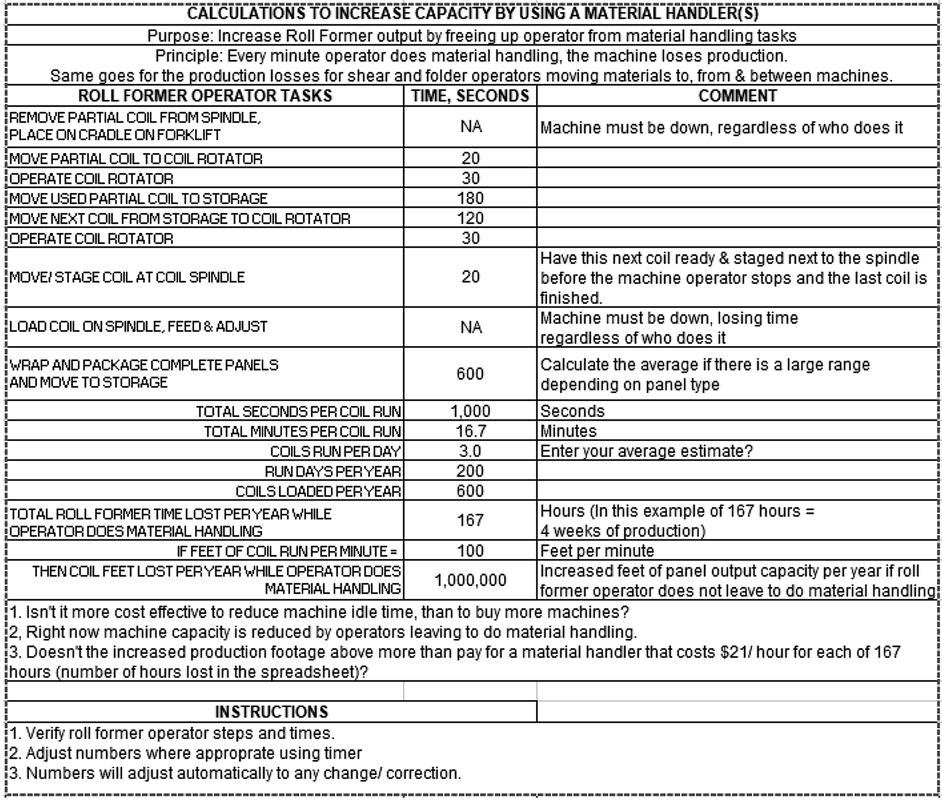

Sample Analysis of Productivity:

The Task

The task was to shorten lead times without any large purchases.

Execution

We do this by eliminating motion, waiting and transport wastes that exist in every process.

Machine operators running roll formers, shears and folders must remain at their machines, producing components. Every time they leave the machine to change coils or to get materials like flats and bring them to their work station, their machine is down, not making parts, increasing your lead time and spending labor on non-value adding tasks.

Time studies are made observing the operators to document each step of their process and how long that step took. It was determined that as much as 25% of their time was lost (wasted) getting materials such as coils or flat sheets. In an 8-hour shift, as many as 2 hours were lost by the roll former operator alone handling materials, leaving the machine down, losing capacity and delaying the production of components. The same is true for shear and folder operators. This adds up.

You can do these calculations yourself for your shop, but keep these two principles in mind:

1) “The only value-adding work your team does are the limited steps in which the raw materials are being physically converted, not moving them around.”

Work that adds value includes roll forming panels, shearing and folding.

Work that does not add value (waste) includes retrieving the next coil, tipping coils, getting a forklift and retrieving flat stock, moving stock from the shear to a folder, packaging, moving finished panels and trim pieces to storage. There are techniques to minimize these activities.

Moving materials does not add value. Many of those steps seem necessary, but only because you have not yet figured out how to eliminate them or shorten the time required.

2) Store materials and tools as close as possible to their point of use (POU).

So how do we keep operators on their machines, keeping them running? We assign one employee to be a “material handler.” They are responsible for keeping an eye on the schedule of work orders and watching the operations closely to know when specific materials must be delivered to a workstation. This person is also assigned additional tasks such as cleaning (5S), organizing, simple maintenance or part time machine operator tasks that fit into available spaces among the material handling tasks.

Results — example

Refer to the sample analysis of productivity shown. Equipment scope in these calculations: One roll former running at about 100 feet per minute.

The client can run 1,000,000 more coil feet per year for the cost of a $21/ hour material handler for approximately 167 hours assuming just three coil changes per day. This is the result of approximately 167 hours per year of machine down time while the machine operator handles material.

Similar results can be achieved for your shears and folders. RF

Stephen Wilkinson ([email protected]) is a Certified Lean Practitioner at RapidLeanCoach.com, a company that focuses on adding value for its clients.