By Sharon Thatcher

Building products utilize a variety of metal. The following is a quick guide created with the help of Steve Swaney, Flack Global Metals, to help users identify what to look for when purchasing and using these metals.

ALUMINUM

Aluminum is defined by alloy description. At one end of the scale is Alloy 1100, referring to pure aluminum, which is very soft and pliable; at the opposite end is Alloy 7075, which is very hard.

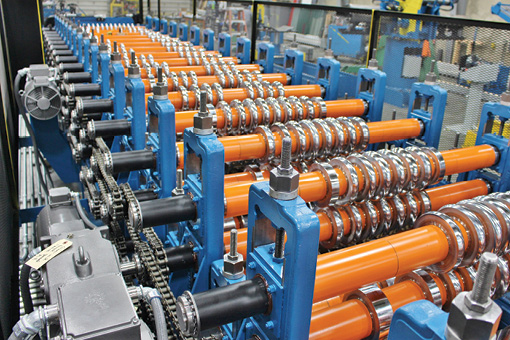

Panel and trim roll formers typically use Alloy 3105 or Alloy 3003. Both have similar properties, the primary ingredient being manganese. The primary difference is how each is created; 3105 is made of recycled aluminum versus a 3003 made with aluminum created in an original smelting process.

Unlike steel, aluminum is not referred to in terms of gauge; rather, in terms of tempers. Designations include the letter “H” followed by either a “1” or “2”. The H defines products strengthened through cold working (or “strained hardened”): H1 is strained hardened only; H2 is strained hardened and partially annealed.

Following the first number, is a secondary number from “2” through “8”. It refers to the degree of hardness; “2” being a quarter hard, “8” being full hard.

Typically building products are going to be within the range of H-24 to H-28 depending on what’s being made. Trim and accessories are H-24; roofing panels or ag liner panels are typically H-28.

Building Products that Utilize Aluminum

- Soffit

- Fascia

- Residential Siding

- Gutters & Downspouts

- Drip Edge

- Flashing

- Patio Covers

- ZBar

- AG Liner Panel

- Shutters

- Architectural Roofing

- Stamped Residential Roofing

Paint Systems on Aluminum

Unlike steel, the aluminum industry includes paint thickness in the coil description; a point that rollformers need to factor in when manufacturing products by specification mandates. Standard thickness, with paint included, is .012 to .050.

Aluminum coil widths are anywhere from 24 to 60 inches.

A lot of commodity or lower-end aluminum products utilize a single coat of paint. There is a primer on the top side. On the back side, if it’s not going to be exposed after installation, a clear coat is used to help lubricate the coil as it goes through the forming equipment. Bare product should not be roll formed as it will have too much friction and drag as it travels through roll-forming equipment.

Two-coat polyesters are used in lower-cost residential applications. A primer should be used if panels will be embossed or if job-site storage is anticipated; the primer ensures that you don’t have wet-stack storage issues.

Flat-Rolled Steel

There are primarily four substrates available through U.S. and international steel mills for building products in the flat-rolled category:

- GalFan® (a super zinc produced by Asian mills)

- Hot-dipped galvanized

- Galvalume® (a trademarked product owned by BlueScope Steel. Similar products include Zincalume® by Steelscape and Acrylume® by US Steel)

- ZAM®

GalFan

GalFan, 5% aluminum and 95% zinc, is sometimes referred to as super zinc. It came into the U.S. through Japan in the mid-1990s. Today, Steel Dynamics and ArcelorMittal produce it. Although a good product that offers corrosion-resistance, it is not used excessively in building panels so is not always available. Most of its use is reserved for appliances and some HVAC markets.

Product attributes of GalFan:

- No spangle

- Low coefficient of friction

- Improved formability/enhanced resistance to micro-cracking

- Excellent paint adhesion

Galfan vs Galvanized examples:

- Galfan GF-20 is equivalent to a galvanized G-40 coating weight

- Galfan GF-30 is equivalent to a galvanized G-60 coating weight

- Galfan GF-45 is equivalent to a galvanized G-90 coating weight

Hot-Dipped Galvanized

Galvanizing is done through a hot-dip process. During the process, steel sheet is coated with a thin layer of zinc to increase its corrosion resistance.

Galvanized Specifications

Material thickness: Most of the domestic mills run coil at thicknesses of 0.013” through 0.130”. Beyond that, it moves to plate production.

Material width: 24” through 72”

ASTM specifications: ASTM A653

Steel grades: EDDS, DDS, CSB Structural Grade 33-80 (DO NOT USE HSLA Steel)

Coating weights: G30, G40, G60, G90 & G100

Hot-dipped galvanized runs the gamut of coating weights from G30, used for liner panel, up to G100 used for many agricultural applications. The architectural community uses a significant amount of G90.

Surface treatments: chem-treated or acrylic coated. Acrylic coated is primarily for animal confinement. Most people don’t put acrylic on the roof.

Attributes:

Galvanized can be easily slit without fear of edge creep.

Galvalume

Galvalume is used widely in the building trade today for long-term corrosion protection. Invented by Bethlehem Steel, and now owned by BlueScope it was the first product of its kind in its category, made of 55% aluminum, 45% zinc metallic coating. Though often referred to in generic terms, GALVALUME is a registered product. Other companies have entered the market with ZINCALUME by Steelscape, and an acrylic-coated product, ACRYLUME by US Steel, all comparable in composition.

Galvalume Specifications

Gauges (in inches): .014” – .045” minimum ordered thickness

Widths (in inches.): 36” – 72” (Steel Dynamics is the only mill currently offering 72 inches. Standard is 50 inches.)

Coating weights: AZ35 and AZ50 for pre-paint applications and AZ55 or AZ60 for bare use.

(To get the 25-year non-perforation warranty you must use AZ50 or AZ55.)

Surface treatments: Rust-preventative oil, chromate passivation, clear acrylic coating

ASTM specifications: ASTM A792 hot-dipped 55% aluminum, 45% zinc; alloy-coated carbon-steel sheet in CSB for trim, and Structural Steel Grades 33-80.

ZAM

ZAM is a highly corrosion-resistant hot-dip coated steel sheet that has a coating layer of zinc 91%, 6% aluminum, and 3%

magnesium.

It is a relatively new product, introduced in 2015 by Wheeling-Nippon Steel. It has shown some impressive results for highly corrosive applications: chemical plants, fertilizer plants, hog barns etc. On the negative side, it is a single-source product at this time and has not gained a lot of acceptance. It is also on the more expensive side and coating weights are measured somewhat differently.

ZAM Specifications:

Material thickness: 0.014” through 0.130”

Material width: 24” through 61”

ASTM specification: ASTM A1046/A1046M Type 1

Steel grades: EDDS, DDS, CSB, STRUCTURAL GRADES 33-80

Coating weights: ZM30, ZM40, ZM50, ZM60, ZM70, ZM75, ZM90, ZM100

Surface treatments: Oiling and Acrylic coated. RF