Cost effectiveness and quality are some of the upmost important factors when shipping and packing your panels. Your customers want and deserve the assurance that they receive their orders without damage or, just as catastrophic, find that there are missing parts or pieces to their order.

Ameripak, a full-service packing solutions company, does its due diligence to ensure that this doesn’t happen. They specialize in:

• Parts and service;

• Custom design;

• Stretch and shrink film; and

• Supply chain solutions.

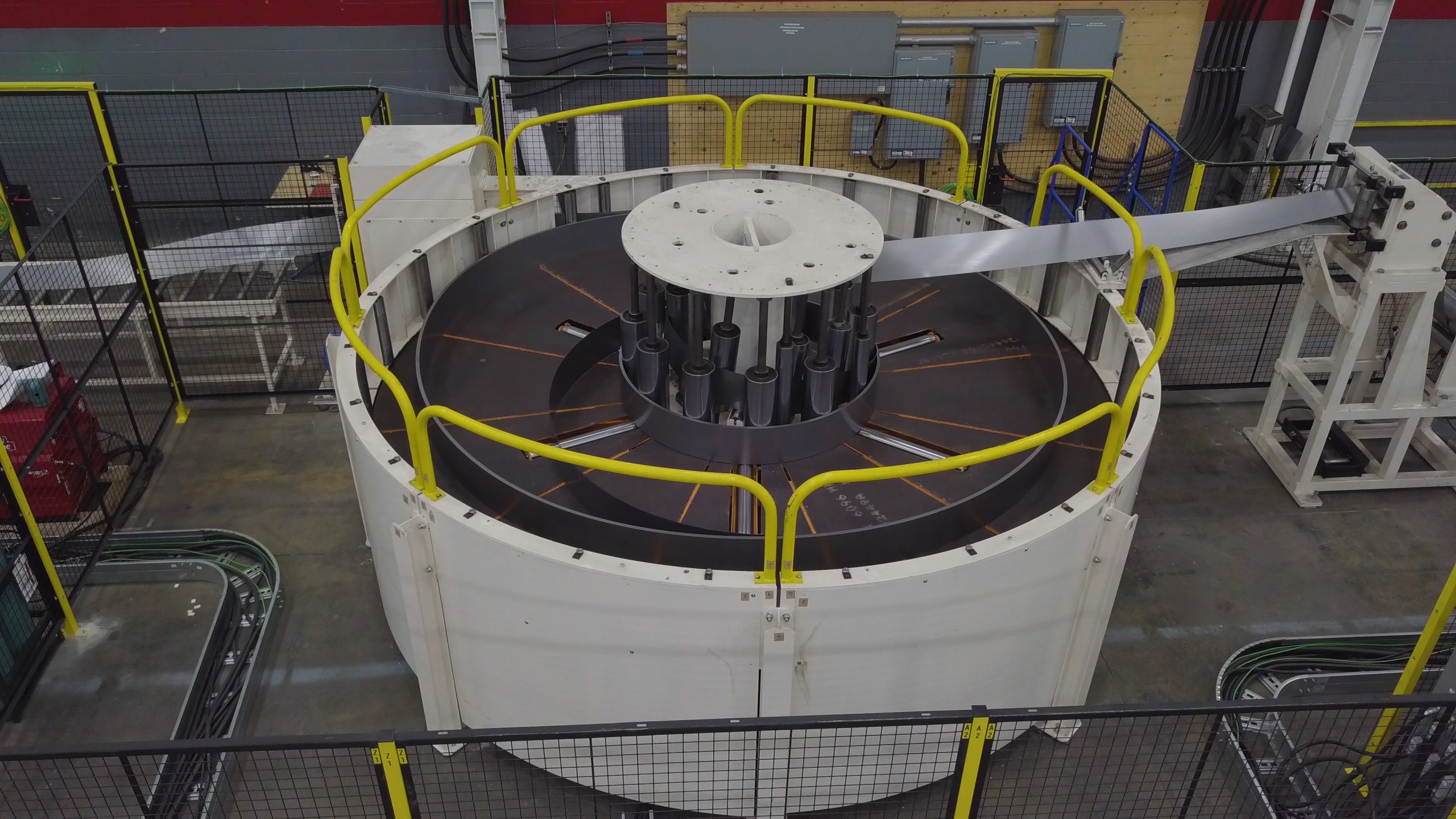

Standing Seam Wrapper

With the growing use of metal standing seam roofing, demand is high and unfortunately, every time your roll former has to stop to allow the last stack of panels to be packaged and removed before the former can be re-started undermines efficiency.

And, because of the delicate nature of the panels, you can’t just toss them on a skid.

Ameripak’s wrapping system eliminates the down time and guess work associated with standing seam production. The “what to do with the panel next” question no longer exists.

Panel Wrapper

Amierpak’s largest wrapper is their SR-44P. This is designed primarily for wide applications such as metal wall and roof panels. The machine has the ability to wrap at high speeds and is available in either semi-automatic and automatic models. This allows your roll forming equipment to produce more panels and not sit idle waiting for the stack of product to be moved out of the way.

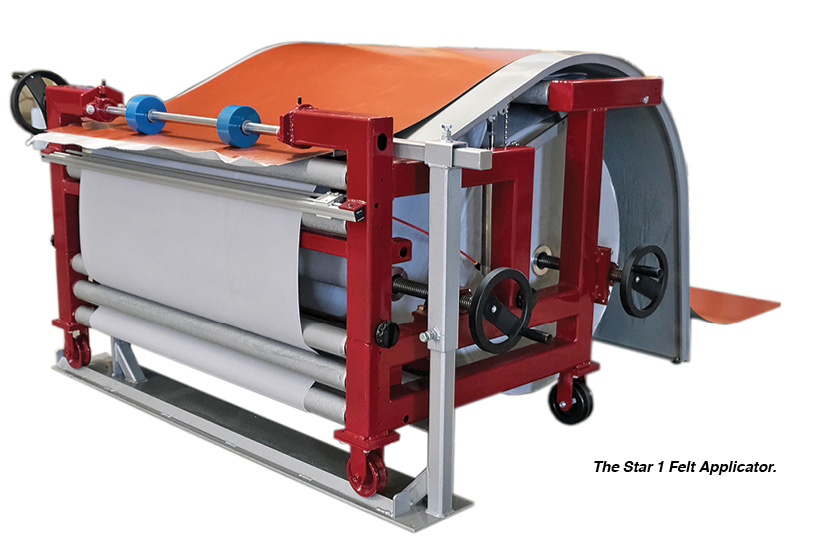

Trim Wrappers

Trim pieces, whether they are metal or not, always pose a challenge when trying to contain numerous pieces as a bundle without damaging the product. Ameripak’s trim wrappers quickly alleviate this issue, allowing total containment of one or more pieces while protecting the delicate painted surface.

Stretch wrap is the method of choice for Ameripak when speed, cost and unitizing the bundle without permanently mis-shaping the product. According to Rob Bowlin, sales engineer of Ameripak Inc. of Kentucky, says that Ameripak’s mission is to serve people who need creative packaging solutions not always found in a catalog.

“Ameripak partners with our customers to develop finish product packaging that serves the manufacturer, our customers and the environment,” Bowlin says.

“Through our creative packaging ideas and our ability to develop solutions that work, Ameripak manufactures equipment that produces result-driven, cost-effective product protection that ensures your customers receive their orders without damage or missing parts. We are sure that our line of metal-wrapping machines will provide the same successful results when you place our wrappers in your production process,” he said.

For more information on packaging and safely shipping your products, please contact Ameripak at www.ameripak.net. RF