The importance of partnership with your metal forming controls provider.

Conduct an internet search on machine controller and there will be an endless list of companies from which to pick. With advanced technology and automation becoming a standard, controllers have also become abundant. At its most basic, the function of a controller is to receive input, which triggers a specific output or activity. Sounds simple enough.

For the metal forming industry, controllers can be categorized as originating from three different sources:

1. General Purpose Automation Companies.

As mentioned earlier, there are a lot of companies that build and provide controllers, ranging from the very simple to the very complex.

Along with an abundant selection of controllers, there are also many general purpose automation companies that have deployed automation solutions within many industries and applications. Why not pick a general purpose automation company for a metal forming controller? Are they not capable of developing a solid controller for a roll former or folding machine?

The answer is yes, their controllers are often quite well made. However, since the controller was developed to fit the widest breadth of functions, there may be significant programming, customization and engineering required to tailor a general purpose controller to the specific needs of the metal forming industry.

2. Factory-Installed With The Equipment.

New roll formers and folding machines purchased today come with factory-installed controllers.

These controllers work well in the beginning since they were designed primarily to work with the equipment in which it was installed.

As industries and equipment needs evolve, more and more activity is automated and integrated with other functions such as ERPs, order processing, accounts receivable, shipping and reporting.

Some Original Equipment Manufacturer (OEM) controllers are built with this integration in mind, while some are less flexible.

Over time as parts fail or become obsolete, the factory-installed controllers begin to lose their shine. And with this change, the support for older equipment also begins to dwindle as focus shifts to newer designs.

3. Metal Forming Controller Companies.

There are controller companies that primarily specialize in the metal forming market, catering specifically to roll formers and folding machines. These companies have a built-in understanding of the industry, developed from decades of experience building solutions just for metal formers. They have the expertise and background to anticipate and design solutions that work for metal formers. With this industry knowledge and experience, metal forming controller companies can complete a controller install for a roll former or folding machine with relative ease.

There is so much more to a controls company than just controls

Picking a controls partner that understands the industry is the first step. There is so much more to consider.

The right controls partner can do more than just provide and support a controller that helps improve efficiency. Controller companies in the metal forming industry have been exposed to many different scenarios and design challenges, and the good ones have solved them. They have worked as consultants, helped troubleshoot and offered new solutions to metal formers. These companies have learned to anticipate and develop innovations that help metal formers automate and increase efficiency. These are the companies that will help metal formers embrace Lean Manufacturing and step into Industry 4.0.

Hallmarks Of A Good Controls Partner

Since there is an abundance of controller companies, what are some traits that make some controller companies rise to the surface? Here are some for your consideration.

• They make great controllers that have stood the test of time.

It goes without saying, the first item on the checklist needs to be the controller itself. Look for companies with a proven track record of building controllers that can withstand the rigors of the metal forming manufacturing environment and the ability to extend the life of the equipment. These controllers should include easy-to-follow instructions for any operator to operate successfully.

• They offer outstanding support.

In addition to a great controller, partners also provide quality support. Look for a controller partner to provide remote access support and extended hours support options. What happens during a line down situation? In moments of crisis, what solutions are in place to help quickly resolve issues?

• They offer training solutions to keep all employees, new and old, well versed.

Training benefits both new employees and also seasoned operators. For the new employee, learning first-hand knowledge from the controller provider gives them a chance to build a strong foundation of understanding and set them for success.

For the seasoned operator, training offers a chance to bone up, fill in any gaps, and more importantly, share ideas and gain tips and tricks that may help them grow even more. Partners that offer continuous training are making a willing investment in not just their customer’s employees, but in the ultimate success of their customers.

• They share best practices.

With experience comes exposure to many different manufacturers, each with its own processes and situations. This unique perspective gives controller companies the ability to share their knowledge and offer guidance and perspective. As consultants, controller partners bring a breadth of experience to help their customers understand and reach their performance goals.

• They are constantly innovating.

Whether it’s innovating to provide the solution that exactly fits the need, or innovating and developing a plan of future releases or upgrades, the right partner knows the needs of the industry will constantly evolve in pace with the demand for newer and more innovative product. These partners have their ear to the ground and will develop a roadmap for future developments to meet the evolving needs of the industry.

• They care about their customers’ success.

By the very definition of a partnership, partners are truly interested in their customers’ success. Partners understand that every customer has situations and challenges that make them unique. Every customer has different challenges and goals. Partners seek to know and understand these goals, and what can be done to help attain these goals.

Seek a partner that welcomes collaboration and the sharing of ideas and goals, even those not directly related to the controller.

• They are throughput partners.

Throughput is an important number measuring the manufacturing performance of a facility. Manufacturers are always looking for effective ways to increase throughput. However, increasing throughput is not as simple as increasing line speed. Partners understand that and will help analyze operations, identify bottlenecks and offer solutions to optimize processes and ultimately reach throughput goals.

• Partners are so much more than just a vendor.

The difference between a vendor and a partner can be explained in this way: vendors will sell solutions and frame the situation to fit the solution. A partner will first seek to understand the situation, ask about the desired goal, and frame a solution that addresses the situation and enables the customer to reach the goal.

Remember this: vendors sell. Partners are interested in the success of the customer.

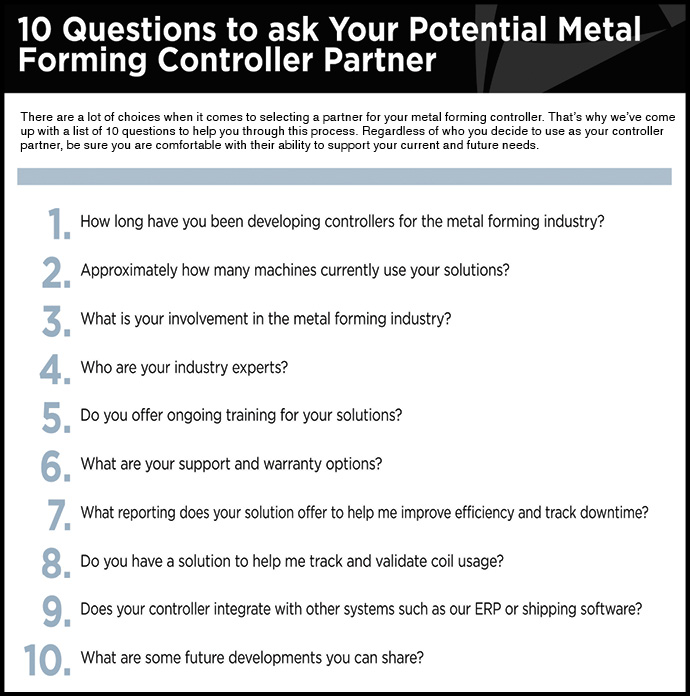

To help you identify a potential metal forming controller partner, AMS Controls suggests that you come up with a list of questions that would be valuable.

A suggestion of questions may include:

1. How long have you been developing controllers for the metal forming industry?

2. Approximately how many machines currently use your solutions?

3. What is your involvement in the metal forming industry?

4. Who are your industry experts?

5. Do you offer ongoing training for your solutions?

6. What are your support and warranty options?

7. What reporting does your solution offer to help me improve efficiency and track downtime?

8. Do you have a solution to help me track and validate coil usage?

9. Does your controller integrate with other systems such as our ERP or shipping software?

10. What are some future developments you can share?

Regardless of who you decide to use as your controller partner, be sure you are comfortable with their ability to support your current and future needs.

For more information on anything presented in this article, please contact AMS Controls at 314-344-3144 or visit www.amscontrols.com. RF

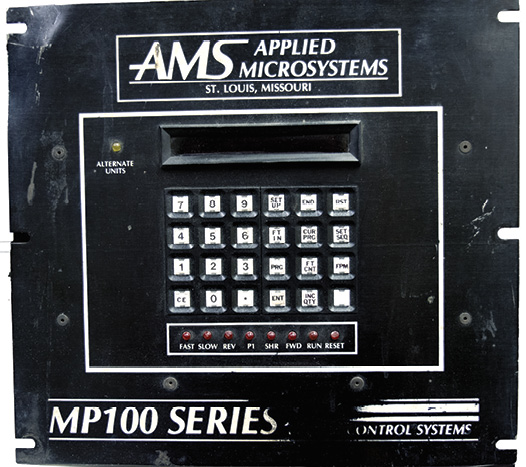

- One of AMS Controls’ early controllers. Built to last, this 30+ year-old controller still works.

- A partner will first seek to understand the situation, ask about the desired goal, and frame a solution that addresses the situation and enables the customer to reach the goal. Remember this: vendors sell. Partners are interested in the success of the customer.

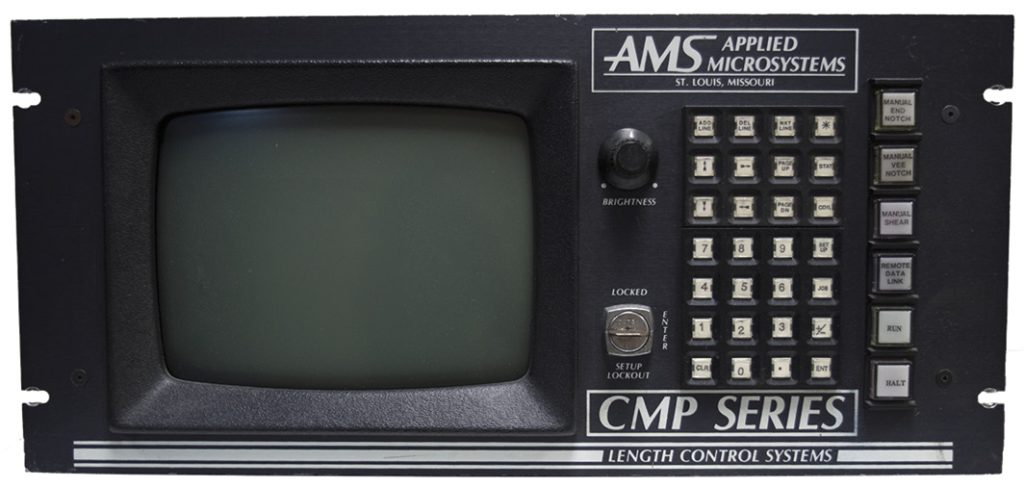

- With every new generation, AMS Controls controllers evolve to do more. This early version includes the ability to control multiple machines.