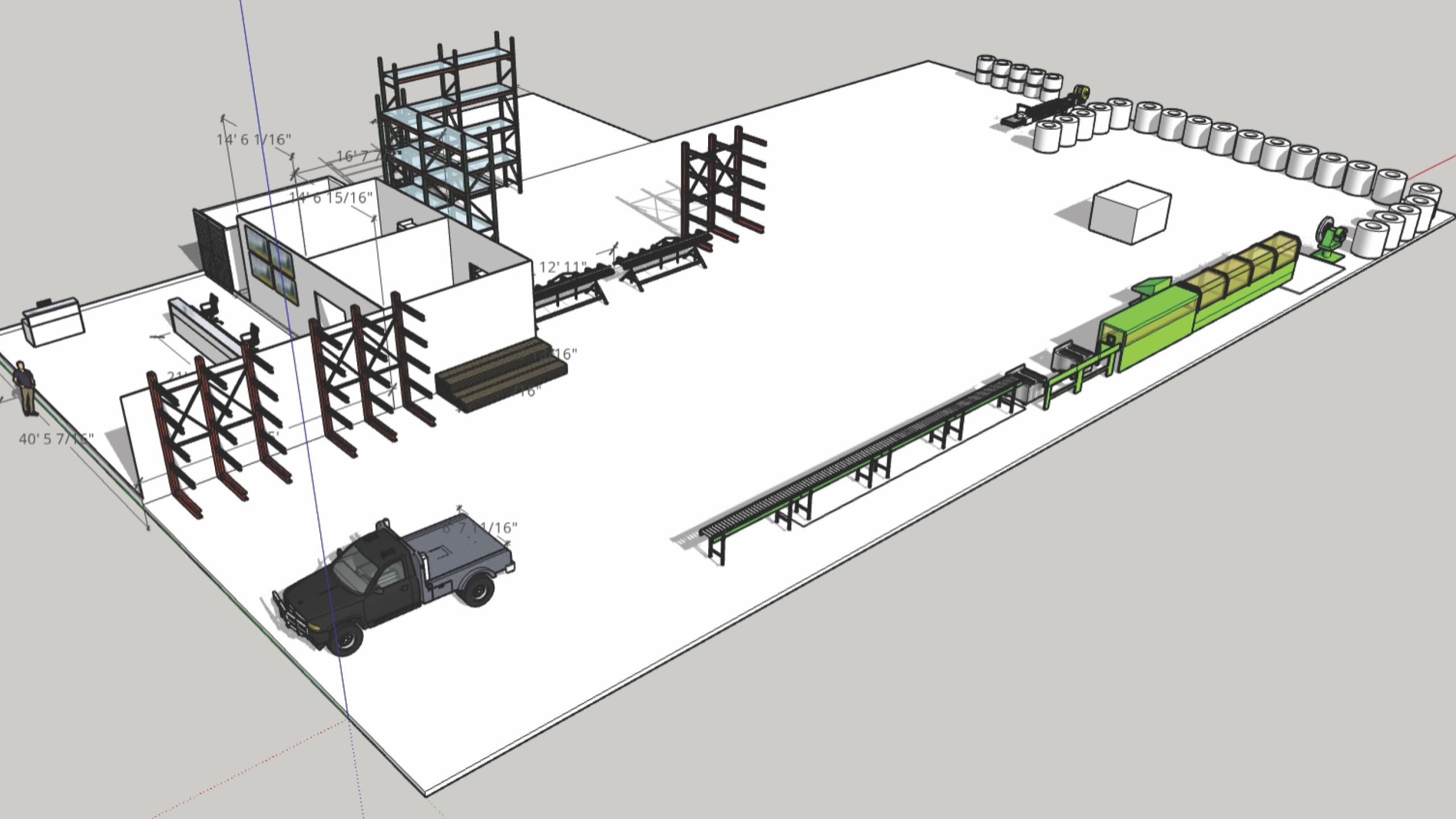

Saving some money in your production process may be as simple as moving machines on your shop floor. Where your machines are located, where you have your materials and finished items stored, and your traffic flow patterns can all have an impact on your bottom line.

It sounds like common sense, but Ryan King, National Sales Manager for CIDAN Machinery, has spent many hours visiting architectural sheet metal shops and has seen how the rush of day-to-day business can interfere with maintaining good shop floor layouts. Rollforming Magazine followed up with him after he raised the issue during an educational presentation at the Construction Rollforming Show last October.

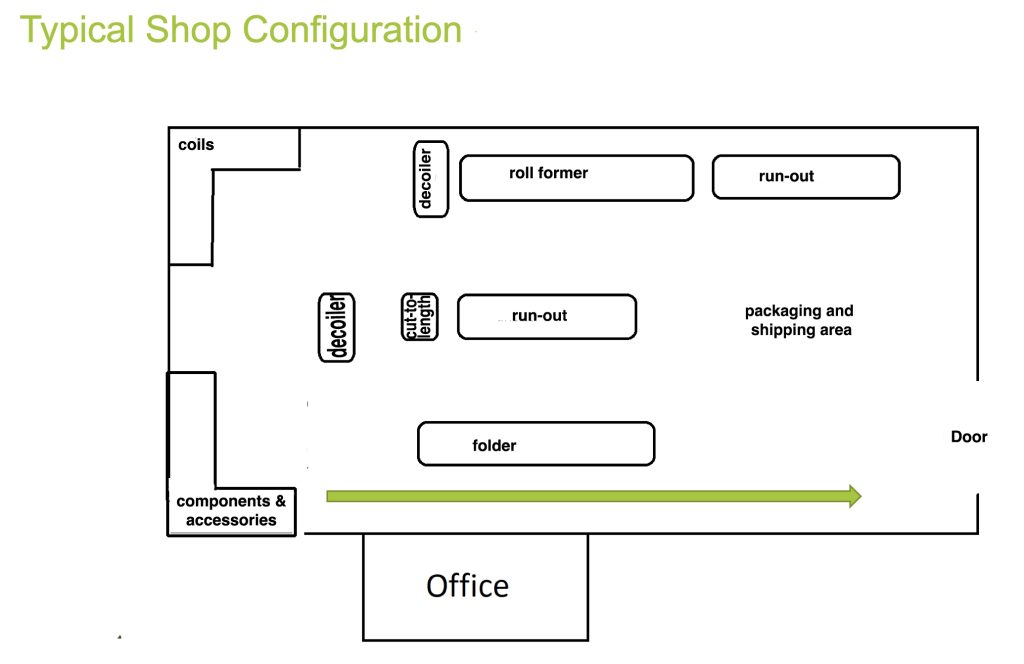

“The most efficient shops …. have a flow from start to finish,” King said. “The raw products start at one end of the building, and the finished products on the other.”

Unfortunately, that isn’t always the case.

Innefficient Layouts

“I’ve walked into many shops and a shear is behind the roll former and the folder is just thrown where they had space at the time,” he noted.

This typically happens in an older, established shop that has seen a rotation of machines. Rather than stopping to reorganize the entire shop, the new machine is moved in with little regard for where it fits best into the production scheme.

“Workers should all be working in the same common area,” King said. “A new slitter should be put with the slitters, a folder should be with the folders, a roll former should be with the roll formers. You may have to move this, this, and this, but in the long run it makes more sense.”

Of course, the size of your shop makes a difference. If you’re a contractor making your own architectural trims on a low-production basis, you’re likely working in a limited space on small or one-off jobs. You may not have many options for shop floor configuration. In such cases it’s “less about revenue and more about controlling the process,” King said, noting that machines should at least be situated in a way that maximizes production by requiring fewer steps for the operator to maximize production time.

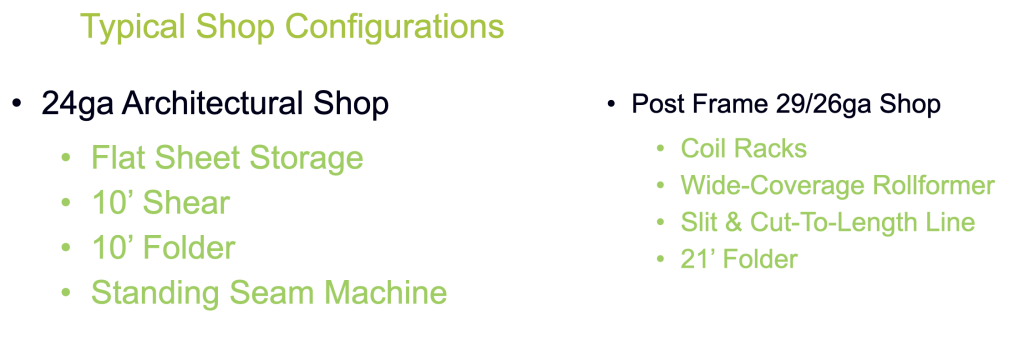

For the typical metal-forming shop running ag/tuf-rib/PBR panels, shop floor configuration takes on increased financial importance: bigger machines, thousands of pounds of coil, product storage and shipping procedures, forklift and truck traffic all play a role in workflow efficiency.

King describes an example where a shop’s slit line is located 20 feet from the folder. It may take less than a minute to get from one area to the next, but over the course of one day those seconds add up. “Every step that [operator] takes is time,” he said. It doesn’t look like much on a micro level but from a macro level, every day that worker is spending 20 minutes a day just walking between those two machines, multiply 250+ working days a year, that represents thousands of dollars, and you’re getting less product out the door.”

For small shops planning to remain small, the dollars may seem insignificant, but if you plan to grow your shop to the next level, paying attention to those small things up front can make a difference as you extrapolate expenses over time and growth.

King recommends using slower times of the year to evaluate your shop floor configuration and make changes. “Moving machines around comes with a greater cost up front,” King said. “You have to move them, rewire them, re-level them, but if you have one machine and you place it far away from the other machines [it can cost more over time].”

Working with New Buildings and Old Buildings

As would be expected, working with a new building versus retrofitting an old building makes floor planning easier. “It’s always going to be easier because you’re working with a blank slate,” King said.

Both Ephraim Esch, owner of Solanco Metal Roofing, Quarryville, Pennsylvania, and Albert Shrock, owner of Cherry Fork Metals, Richmond Dale, Ohio, agree, having both experienced the benefits of moving from old to new buildings in recent months.

Shrock operates primarily with jobsite machines but moved from a conglomeration of five buildings into one large building. The new building is used for material and equipment storage, a trim shop, and office.

In his old facility, he said, “I had more space, but it was a combination of five different buildings kind of stuck together.” Now all under one roof, the new building provides easy flow-through from one area to the next. “We’re a lot more organized,” he said. And he likes the fact that he can easily look from his office into the shop area. “From the office I can see the inventory; you don’t have to walk into another building to check something out,” he said.

The new building is also climate controlled to better protect his supply and machinery investments.

Ephraim Esch also has a better sense of organization with his new shop, which replaced a modified chicken barn. He has shop employees doing the metal work, so relied heavily on their input regarding the shop floor layout before moving in. “I’m not a very good designer,” he admitted. He relied on his employees to help with the layout. “We spent a lot of time, I and the employees, talking it over. We discussed this a lot,” he said. “I’m not in the shop a lot myself, so I wanted them to be comfortable with it. I haven’t heard any complaints. That’s not to mean we’re not going to make any changes, but it’s a whole lot better than we had it before.”

To help with production, he installed another uncoiler to reduce the switching times between the trim line and roll-forming line.

Spacing Considerations

Whatever square footage of floor space you are working in, Ryan King advocates for spacing machines close together without hindering production and safety. As well, the ability to access maintenance areas comfortably should be taken into consideration.

It comes with the caveat to check local codes. “There are some cities and municipalities that have codes for the distance machines need to be from walls and that sort of thing,” King advised.

Step-Saving Accessories

A way to increase productivity without moving machines is adding accessories that help reduce steps. Two commonly seen by King is a table on wheels that can be rolled next to a production machine to hold materials or finished product until ready to wheel over to the next step in the process, “so at least it’s one movement, not [a constant] back and forth,” King explained.

Hand-made ramps are also used to help hold heavy materials as they are being fed into the machine.

Yet a third device are J-hooks or hangers attached to the top of the machine. These are used to hold blanks ready to be formed in a 10-foot folder, “so now when they bring in the next flat sheet, it’s right there in front of them.”

Truck Traffic

When planning shop floor configurations, an important area to consider is shipping. While not always feasible in some shops, the most efficient buildings accommodate drive-through traffic so trucks can enter at one end and exit the opposite end. This isn’t just a safer pattern but is more efficient by allowing one driver to pull in just as another one is leaving. It also helps avoid damage that is quintessential at manufacturing sites: damaged doors, damaged product, and damaged machines caused by backup mishaps.

If a drive-through is not possible, King said having space to load trucks indoors is safer and more efficient, particularly when shipping long panels. As he noted: “When loading long panels on a truck or trailer, it is difficult to drive the panels through a door with your forklift instead of simply loading inside the building.” RF

Sharon Thatcher is the former managing editor of Rollforming Magazine. She is now an independent writer living in Ohio.