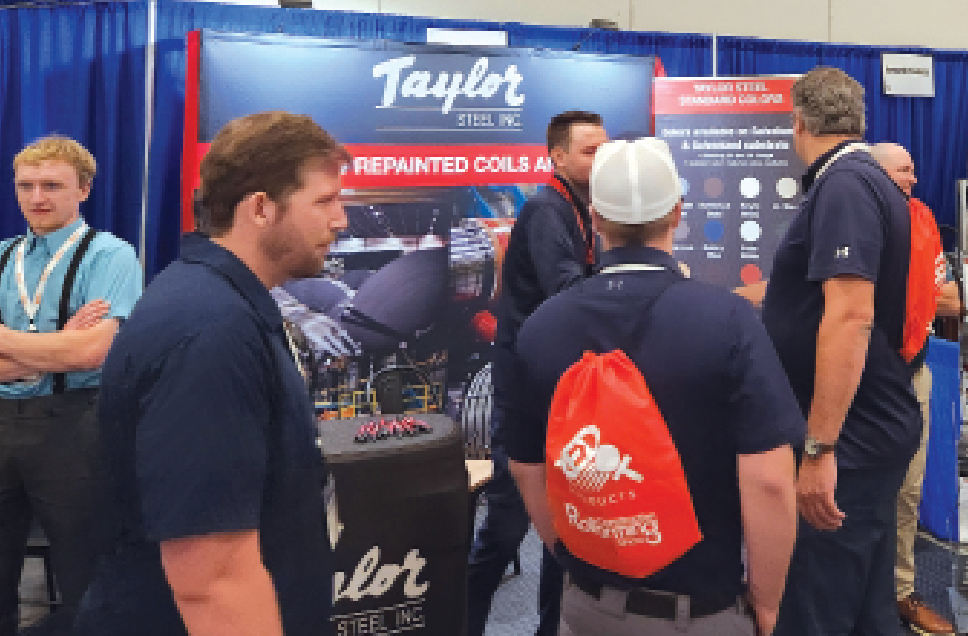

DeVos Place in Grand Rapids, Michigan, was the host venue of the fifth annual Construction Rollforming Show, which was held September 18-19, 2024. This trade show is the only event fully dedicated to forming light gauge metal for the construction industry. This year’s event was the largest yet, with nearly 70 exhibitors filling the show floor and a record-setting number of attendees.

Once again, exhibitors and attendees benefitted from the tightly focused expo. Brad Wasley of AceClamp said, “I very much prefer the intimate setting of a smaller regional show that gets to the contractors that don’t care to participate in the international shows that are much larger.”

Acu-Form’s Wayne Troyer shared his goals for the show: “Meeting new and existing customers, making friends, and selling machines. The CRS was a great place to do just that! The show was made up of a lot of quality people.”

Noah Oberholtzer of Hixwood had similar goals: “My main goal for the show was to meet new customer prospects and I believe we succeeded in doing that; however, we were also overwhelmed with how many existing customers were there that we got to meet and talk with. For some of them, it was the first time we got to meet them face to face. Overall the show was a great experience!”

It was the first time Lin and Neil Warner exhibited the SteelGrip SAMM. Neil had this to say about the experience: “Our SteelGrip SAMM crew met so many nice and friendly people at the 2024 Construction Rollforming Show. It was a fun and informative experience to have conversations face-to-face with people committed to being better skilled in the steel building supply and construction industry.

“My wife, brother-in-law, and I were able to show ‘hands-on’ — or rather ‘feet on’ — our new Safety Assist Magnetic Mats-SAMM mats. Attendees were actually able to lift, place, and walk on an 8/12 pitch steel ramp using SAMM. Patrons realized safer footing and time savings were possible. Thanks to all those who put the show together.”

Also new this year was the Construction Industry Forum. Moderated by Source One Marketing’s Randy Chaffee, this inaugural panel consisted of professionals who are experts in various aspects of the construction industry. The panel consisted of Ben Schmidt, The Bradbury Company; Steve Swaney, Mid South Aluminum; Bob Kula, Mill Steel; and Mike O’Hara, Levi’s Building Components. The group has combined construction-industry experience of more than 200 years, which attendees could take advantage of throughout the open forum session. The panel addressed several important questions and issues that construction metal forming businesses face, providing invaluable advice for those just starting and seasoned business veterans. (See sidebar.)

Returning features favored among attendees were the educational seminars, complimentary breakfast, and the Rest Stop Retreat. This year, the Rest Stop Retreat area was sponsored by Acu-Form and AkzoNobel. Acu-Form providing seating and AzkoNobel supplied coloring bags for all the children in attendance. Shield Wall Media recognizes that a large part of the construction roll forming industry is made up of regional, family-run shops; we are dedicated to supporting this important segment of the industry by welcoming family participation.

All proceeds from attendee entrance fees from the 2024 Construction Rollforming Show were donated to the Independence Fund. The Independence Fund is a 501(c)(3) organization that helps catastrophically wounded veterans by offering programs and services that promote the health and independence of American servicemembers, combat veterans, and their caregivers and families. The organization’s initiatives include mobility and adaptive technologies, suicide prevention, caregiver and family support, and advocacy for veterans with agencies at the federal and state levels. (Learn more about the Independence Fund at https://independencefund.org/.)

All photos by Shield Wall Media Staff

Make Rollforming Great Again” hats and T-shirts were free takeaways at the Shield Wall Media booth.

Metal Rollforming Systems’ Rich Boegli (right) presented the talk “Rollformer & Associated Equipment Maintenance.”

New Industry Panel:Ben Schmidt, Steve Swaney, Randy Chaffee; Bob Kula, and Mike O’Hara

MWI Components recently debuted Metal Wrap,

The Star 1 Felt Applicator draws attention when it’s demonstrated.

Little Harveys booth displayed samples of specialty steel coil.

Stoll Metal Works exhibited a “salesman’s sample” press brake. Normally the brake would be 21’ long.

The next Construction Rollforming Show will be held at the Dayton Convention Center in Dayton, Ohio, on October 1-2, 2025. Watch the pages of Rollforming Magazine and constructionrollformingshow.com for show updates as they develop.

Show Brings Out Roll-Forming Business Advice From Industry Experts

The 2024 Construction Rollforming Show, produced by Shield Wall Media, featured the tried and true elements event-goers have come to expect. It also featured some new ones, including the Rollforming Industry Panel. This new show feature was held the morning before the expo floor opened so attendees would not have to choose between meeting exhibitors and participating in the panel discussion.

Moderated by Randy Chaffee, Source One Marketing, the panelists included Ben Schmidt, who has been with The Bradbury Company for 19 years. He has served as industry sales manager for the metal building, trim, and decking industries since 2020.

Credit is due to Steve Swaney of Mid South Aluminum. After giving a talk at the Post-Frame Builder Show, which is also produced by Shield Wall Media, Steve suggested hosting a panel discussion so whatever questions attendees had could be addressed.

Steve followed his father into the industry and has spent 42 years in the prepainted metals sector. Throughout that time, he has worked for mills, coil coating companies, and service centers.

As mentioned earlier, Randy Chaffee served as the panel moderator. He has more than 40 years of experience in the metal roofing, post-frame, and metal building industries. He owns Source One Marketing, a manufacturers’ rep agency, and is the host of Building Wins Live, a weekly vlogcast and podcast for the building materies industry.

Panelist Bob Kula is the sale manager for Mill Steel’s Building Products business unit. Hailing from Houston, he’s been in steel for 33 years, 28 of which have been with a service center and five were with National Steel (now known as United States Steel).

The final panelist was Mike O’Hara, who is the national sales manager at Levi’s Building Components. Mike has 27 years of construction sales and marketing experience in a variety of professional trades.

Show personnel gathered questions ahead of the event to get the conversation started. The first question asked what are the questions that rollformers should be asking suppliers as they start lining them up for their business. O’Hara advises that you should make sure you understand lead times. “I think an important thing regardless of what you’re buying from your suppliers is to understand their lead times. Is there seasonality in that service. You’ll probably know your competition to begin with. You might want to reach out to a fellow rollformer in the area and talk to them about who they’re working with. And then once you decide, try to get a sales rep out there right away. A lot of these sales reps have a lot of experience and they understand the market and they can really help you build your business.”

Bob Kula adds, “ My biggest thing, being a coil supplier, would be the financial end of it. Talk to your suppliers. Normally when you go into roll forming, you were either an installer or you used to work for a former company and you’re starting your own business. You probably don’t have any credit. If you were an installer, you have some credit, but it’s not enough for a truckload of steel or multiple truckloads of steel.

“And and be honest with the credit people on the on the supply side,” Kula continues, “whether it’s the components or the steel. Tell them ‘I’m new’ and most times they’ll work with you and grow that credit line.”

Steve Swaney advises you know what your immediate objectives are before you begin. “Some of the main questions to ask suppliers would be, when you’re looking at a new business as a roll former, are you going to be a component supplier, or are you going to be a turnkey building products supplier?

“Are you going to have your own your own crews? Are you going to sell wholesale? Are you going to sell to the contractor sector? I think those things are very important. It’s hard to be a blended company and do those without somewhere in the not-too-distant future, having some conflicts and issues.

“And then line up your supply chain based on where you think you’re going to be if you’re a component guy. You’re going to, obviously, focus on panel and trim. If you’re going to sell turnkey buildings, then you obviously have to supply a number of things, including fasteners, insulations, skylights, things of that nature. So, have a good concept and an idea of what you’re looking to do going into your business and also know your competition in your region to know where you your niche may be.”

Ben Schmidt addresses equipment considerations: “As far as the equipment side of things, equipment suppliers are gonna be selling you folders and roll formers. But probably the biggest thing is when you’re talking to somebody, you wanna make sure you understand when that machine’s in there, its job is to produce parts. So if you’re not making parts, you’re not making money. Right? So the big thing is to understand the equipment supplier’s ability to support you — the end user. And specific to that point, find out: 1) Do they have technicians that travel? And then, 2) How many of them are there?

“And so it means if you have just one or two guys out there, then you don’t want to be waiting weeks upon weeks as we come in and fix your machine.

The other thing Ben recommends is asking them about the service capabilities. “I’d ask them about if they can dial in and support you remotely from a home base, from a headquarters area. That’s very important. And then also ask where the parts come from because machines break. It doesn’t matter whose machine it is. The goal was always ‘How do we get that machine back up and going quickly.’ And if you can go to Grainger versus having to wait for a part from wherever, that’s very, very important.

“And then as far as questions to ask or a question that I’m going to want to know if you’re talking to me,” he continues, “and it’s probably the biggest the biggest challenge and the same thing for the guys on the steel side, is volume … are you currently buying out X number of truckloads a week, a day, what have you, so we can make sure we provide you a quote for the appropriately sized equipment.”

Another important point the panel addressed is common mistakes newcomers make and how they can be avoided.

Mike says, “Well, I’m sure that some of the equipment folks will say buying subpar equipment isn’t probably going to help your overall product.” He adds, “Customers like options. They like unique colors. I think as we drive towards premium products, we can help each other improve our margins, our reputation. I think it’s really important that we attempt to elevate this industry.”

Bob cautions, “Don’t try to be everything to everybody. If you were an installer before and now you’re gonna roll form a certain panel, roll form one panel. Don’t try to roll form 10 like McElroy Metals does, or 20 panels. You’re gonna go broke. Offer six or eight standard colors and then everything else offer as special order. If you’re good and you have service, people will come to you eventually. But if you overpromise and underdeliver and you don’t have the funds to buy the coils or the material needed to make the panels, you’re gonna be in trouble.”

Steve adds to the advice: “Make sure you have enough business to substantiate a roll former. I mean, if it’s only running five to 10 hours a week, it’s probably not the right investment for you at that point in time.

“Know your business going in.

“Know your competition in the market as far as what you’re going to do.

“Make sure you research your supply chain. I mean, find out who are the good suppliers that are heavily invested into the markets that you plan to serve and utilize them because they can definitely help you with reducing your inventory, bringing stock in. … And look at the products that you plan to make and where you seem to have demand and then direct your business in that direction going forward.”

Ben shares sage advice regarding equipment and shop layout: “As far as on the equipment buy side, before you have the equipment, the one thing that we always encourage people to do is whatever model of equipment, whoever you’re working with, go see that piece of equipment making product in the field before you make that financial commitment because it doesn’t matter if you were looking at a $1.5 million high-speed, highly automated ag panel line or an $80,000 one from overseas. If it’s not making a product that you can sell that’s consistent with what you’re currently using and then reselling, even at $80,000 it’s an expensive paperweight. Go see the machines making the product and feel comfortable on that side.

“After you have the equipment,” he continues, “probably the [newcomer mistakes] that we see would be plant flow. As you put your plant together, there’s a lot to it, but it’s not rocket science. What you want to have is all your raw product, your coil at one end and your finished product at the other. And it flows through so the material doesn’t have to move back on itself.

“Now, of course, the world’s not perfect. Sometimes you gotta start with a facility that may not be the perfect size, but if you can go from raw to finish in a linear motion, it’s a big deal.

“The other thing is when you’re talking about facilities, no matter what equipment it is, you need a proper foundation. If you don’t have a proper foundation for a flying shear, for example, it’s gonna eat up your concrete. If it’s an uncoiler that’s gonna rotate, it’s gonna eat up your concrete. So having proper anchoring is huge.

“You’ll spend more on the foundation, but it’s important because this equipment, if it’s not leveled in, it won’t make product the way it needs to, the way that you expect it to.

“And then probably the last thing that I would say is as you’re looking at your plants, having a way to store finished bundles, because roll formers will make a lot of panel. But the key is how do you get the finished product away from the line?

If you wanna go after, if you wanna do shrink wrapping, if you’re gonna block and band or what have you, but having a way to stage those finished bundles is a huge deal as far as being able to get product out the door.

Several more important questions were addressed during the session. You’ll find a continuation of the discussion in a future edition of Rollforming Magazine. RF