By Karen Knapstein

If you roll form corrugated panels, you may wish to consider offering closure strips. They are a simple — but critical — component used for closing the gaps in a metal roof system.

As you know, corrugations in metal panels give the material its strength and rigidity. The downside of the corrugations is there are gaps at the eaves and the ridge when panels are installed. If these gaps aren’t closed, they will allow pests, dirt, debris, rain and snow to find their way into the interior of the building. To close the gaps, it’s standard practice to install closure strips during the initial roof installation. Here’s a brief and simple rundown of what they are.

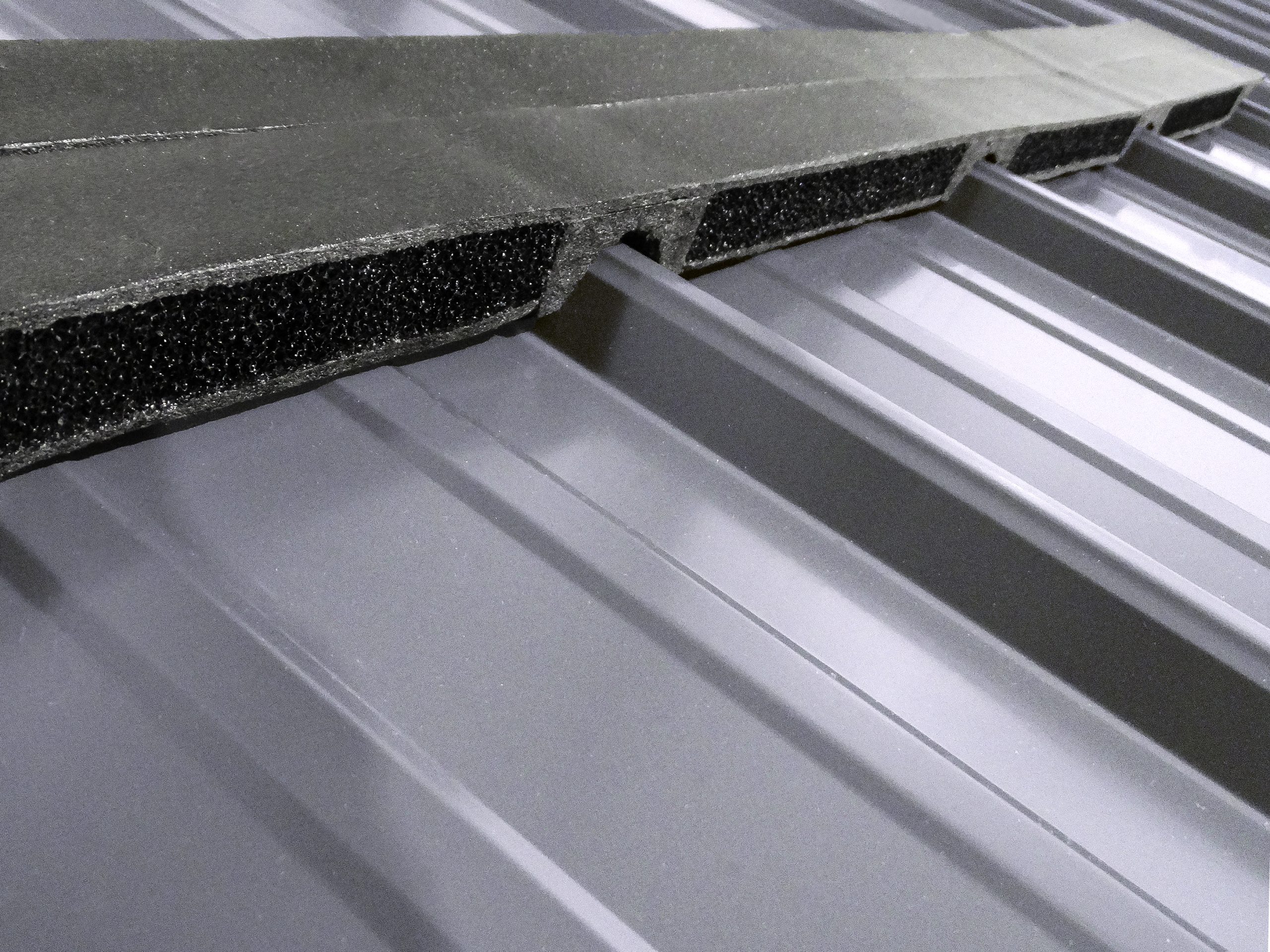

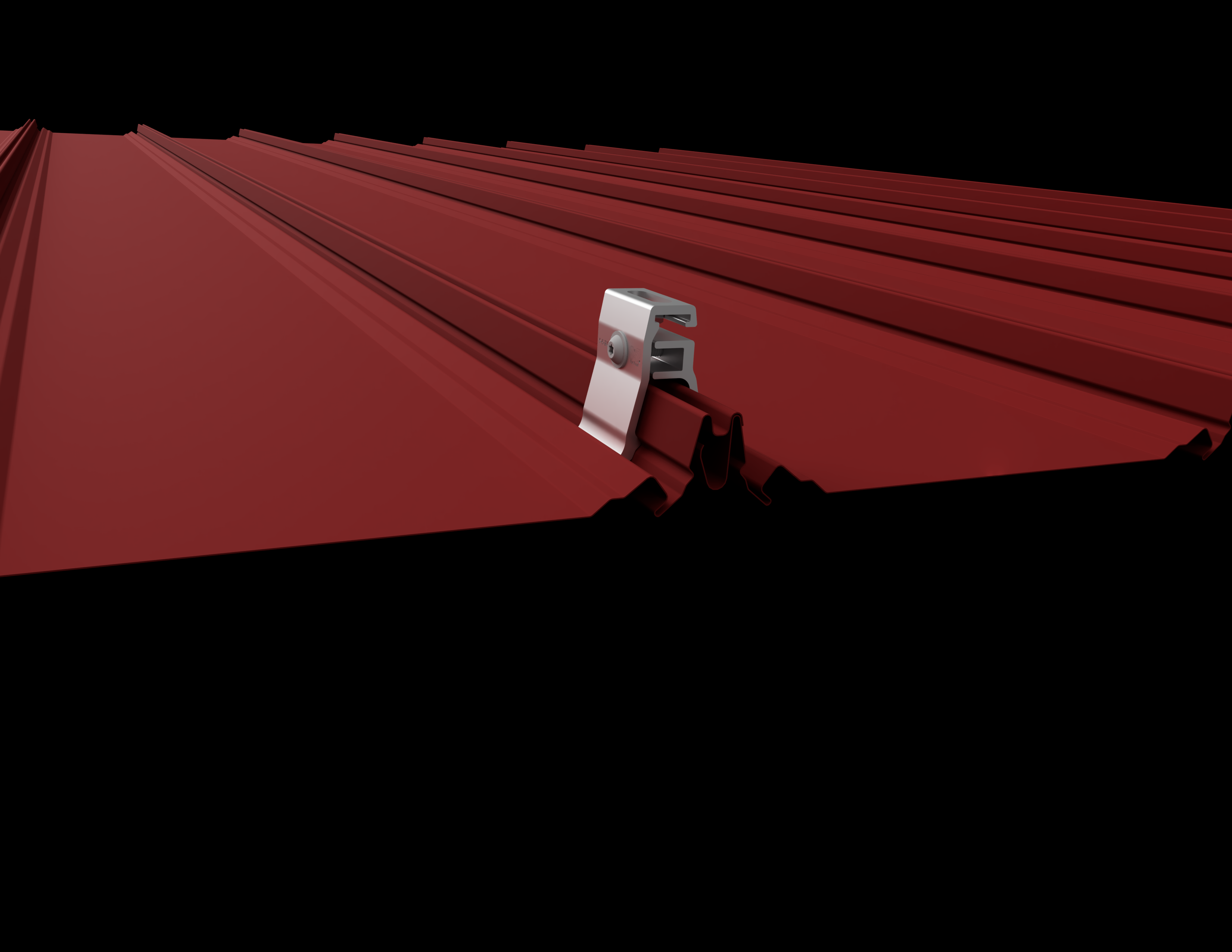

Closure strips are a very simple product that prevent major problems from developing in post-frame and metal buildings. They are profiled strips made of foam. Each strip, which is usually 1”-2” wide, has a profile that fits a specific panel profile. (Strips that fit standing seam are also available.) They are manufactured with or without pre-applied adhesive. Universal closures are flat strips of open-cell polyurethane foam are made to work with any profile. The foam compresses and expands as necessary to fill the gaps.

Inside closure strips are installed under the eaves to seal the inside of the panel profile. Outside closure strips are installed at the ridge between the outside of the panel and the ridge cap.

Closure strips come in both open cell and closed-cell configurations. Open cell strips allow air to pass through while keeping out dirt, debris, pests, and precipitation. Closed-cell strips, which are made of a much denser material, effectively seal the openings, allowing nothing to pass through.

The type of building is a determining factor for whether closure strips are needed, and whether open- or closed-cell closure strips should be used; maintaining the functionality of the building is critical. If the building is an open-air building, such as an agricultural shelter, closure strips are not necessary. Enclosed buildings are another story.

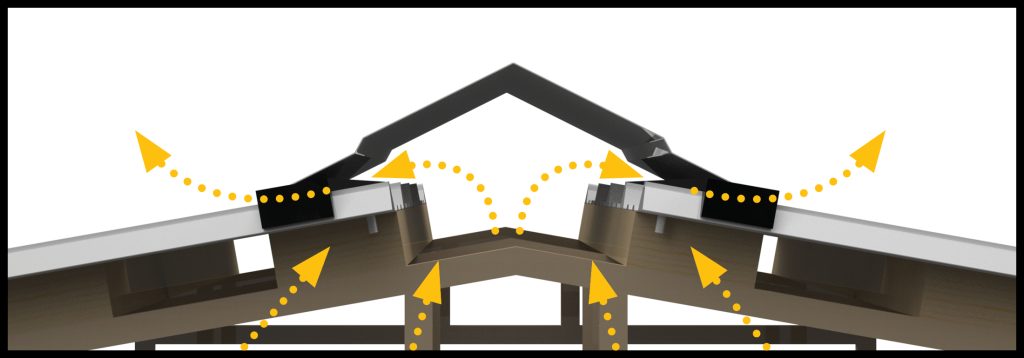

Adequate roof ventilation is critical for the longevity of metal roofs. So, when ventilation is needed, open-cell closure strips are used. Outside open-cell strips are frequently installed at the ridge where hot air accumulates. Hot, moisture-laden air is allowed to escape through the open cells of the foam, but the cell structure doesn’t allow dirt, debris, or precipitation to enter.

Open-celled closure strips at the eaves close the gap to prevent wind-driven rain, varmints, and pests from entering, yet they allow fresh air to enter as part of a natural ventilation system. If a building is heated, it will need ventilation.

IMAGE COURTESY OF MWI COMPONENTS

Traditional closure strips are made 3’ long to fit the width of the panel; they’re beveled at the ends to fit together. However, rolls of closure strips, which can measure anywhere from 10’ to 50’ long, are also available. The 50’-long rolls can be a bit unwieldy; it can be difficult to lay it out in a straight line on a windy day.

Closure strips with pre-applied adhesive are easier to install; the adhesive holds the foam in place while the panels or ridge cap are being installed. Most roofers opt for closures with pre-applied adhesive.

Foam degrades quickly when exposed to the weather and UV. Quite often, closures will be placed far enough under the panel that they aren’t exposed to direct sunlight. They can also shrink over time and lose their effectiveness; if strips have a good density, they will last as long as possible. Some are made with UV stabilizers and fire retardant additives. Be sure to read the product specs closely to learn about expected life spans.

Closure strips are a necessity for closing a metal building envelope. While there are hundreds of metal panel profiles available, you may wish to consider having on hand universal closure strips or closure strips for the profiles you manufacture. It’s a product that builders and roofers need; if you can supply them with it, it will save your customers a trip and drop a little extra money to your bottom line. RF