By Manfred Binder, Sales Director, Inline Color Measurement, X-Rite

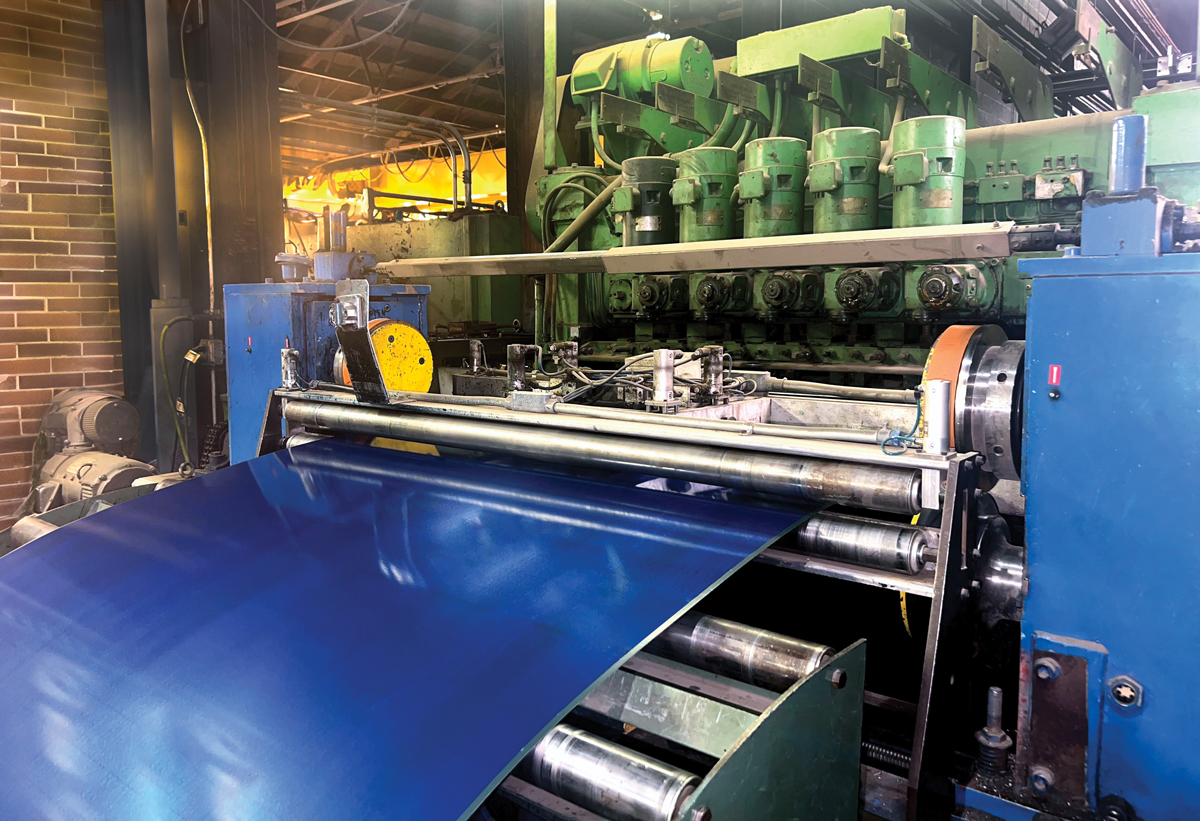

Coated steel and aluminum panels are an integral part of the construction industry, commodities, and other applications. As design trends expand to include custom color work with intriguing new colors, manufacturers must ensure first run accuracy and repeatability. Color must be constant throughout the façade and from one product to the other.

In this way, color has become a primary quality criterion. If color is not consistent, it is easily discernable. If one panel on a roof or building has a different shade, it is noticeable immediately. When color is not consistent, products need to be reworked, scrapped, or sold at a discount. Not only does this impact a manufacturer’s bottom line, it can have significant impacts on sustainability efforts.

For coil coating, the challenge is identifying color drift early on in manufacturing. However, this is not easy for manufacturing processes. The speed of manufacturing means that operators cannot remember or identify the exact color coming off the line. If a coil is produced, the operator has no chance to see color shifts during the process, as they are slowly fading. The operator can only realize color differences when the samples are side by side, as if they were mounted on the facade.

Luckily, advances in color measurement technology can help coil coating manufacturers catch color drift immediately and avoid expensive waste.

Measuring in a Lab

Color measurement equipment measures color independent from light conditions and human judgement. Color measurement has become a standard for all laboratories because it provides reliable data for incoming inspection of raw materials as well as final inspection of the produced coils. All data are stored and thus traceable. The laboratory is an important instance when decisions about color must be made. It is here that manufacturers formulate and define the coil coating color standards. These professionals need to answer questions like: “Can we ship this product in the specified color?” or “Did we ship the identical color to last month or last year?” or “Is our color consistent run after run?”

But how does this information help the operator run his machine? Very little! He produces a coil, which is rolled up at the end. After finishing one coil, a sample is taken and brought to the laboratory. Only then does the operator get the result about what was produced. It is like driving a car with your eyes closed and only occasionally glancing at the road to correct your direction. Nobody would do this because it is too dangerous. So, why should we do this on the coating machine?

When it comes to quality control, there is a popular saying: “You can only control what you measure.” If color is important for a product, it must be measured on the production machine to allow the operator the ability to make the right adjustments before color is out of specification.

Production Environments Require Inline Color Measurement

Measuring color in a laboratory is very different than measuring on a production floor. In a laboratory, the spectrophotometer is in a clean and consistent environment. The temperature and lighting are constant, and there is very little dust. The sample is cooled to room temperature and can be directly placed on the spectrophotometer for an easy measurement reading.

However, the scenario is completely different on the production machine. When measuring during production, the following need to be considered:

• Measurements must be taken without contact so the coil strip is not damaged or scratched.

• Measurements cannot be influenced by the normal fluttering and ambient light on the production floor.

• The temperature of the room and the coil strip can influence color measurements. If measuring a hot coil, the color values at room temperature must also be considered.

• Measurements on the line need to be as precise as in the laboratory.

• The production line moves fast.

Measuring color during coil production is no easy task. Luckily, advances in inline color measurement and software are making it easier than ever to control and monitor color during coil coating.

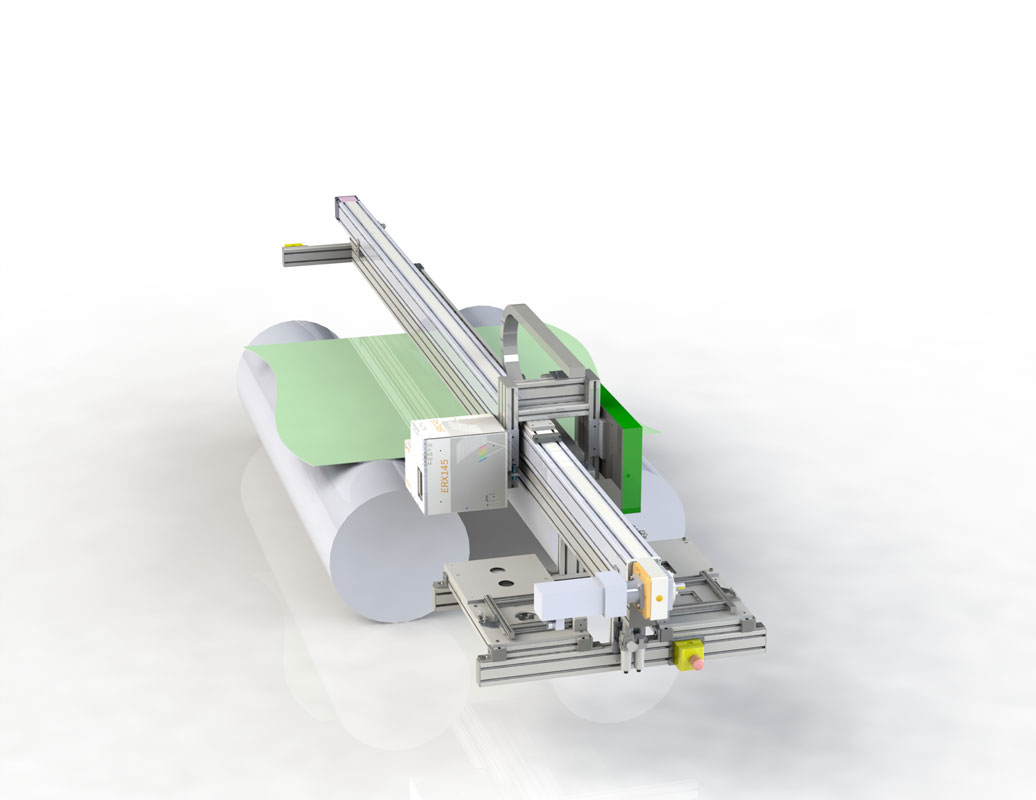

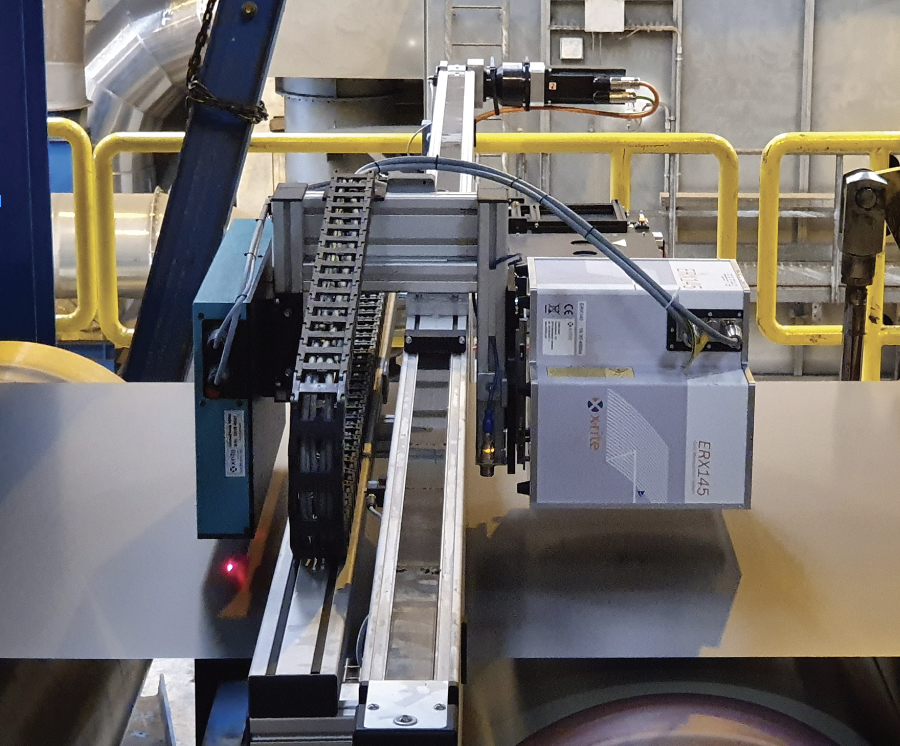

Today’s inline spectrophotometers are mounted on a traversing beam to measure the color in cross direction, without contact, during production. With this information, the line operator can control the nip press of the coating line and the color kitchen operator can see how the color at the machine develops. If color starts to drift, immediate actions can be taken to keep the color within the specified limits.

Where to Measure

When adding inline color measurement to the production process, there are two places where the color can be measured:

1. Directly after the water quench after the final coating. Placing an inline instrument here captures color information early in the manufacturing process to predict what the color will looks like. One disadvantage is that the coil is still hot and color measurement readings will need to be recalculated to room temperature. However, QC software can be used to perform these calculations for an excellent correlation to the laboratory system. This is explained in the “Thermochromism” section below.

2. After the final accumulator. Here the temperature is cooler, but unfortunately not stable. Depending on the position of the accumulator, the temperature can change, so thermochromism control is required. Another disadvantage is the speed to the strip is not constant. It has no influence on the quality of the color measurement, but the measurement spots on the stripe are not evenly distanced as the traversing beam has a constant speed.

All in all, the advantages for the color measurement after the water quench are higher. When possible, it is recommended to measure after the water quench. Measurement after the accumulator should only be considered when there is no space available before.

Thermochromism:

How to Compare the Hot Coil to the Laboratory

Product specifications and color tolerances are often very tight for coil coating. Unfortunately, color can change with temperature. This is a reversible process and it is called thermochromism. For example, red, orange, and yellow colors can appear darker and less saturated at higher temperatures.

On the production machine, the coating is cured in an oven. After leaving the oven the strip is quite hot. Even the water quench will not decrease the strip to room temperature. If the inline color measurement is taken here, we need to consider this color shift and recalculate the measured values to room temperature.

Inline devices, like the X-Rite ERX145, have a built-in pyrometer to measure the current temperature of the coil right at the measurement spot. X-Rite ESWin QC software receives the color values with the real temperature and recalculates the values back to room temperature. Even when the temperature of the coil changes, the measurements are constant and correspond to the measurement in the laboratory at room temperature.

To specify the thermochromic effect, the same instrument is mounted on a heating and cooling table for use in the laboratory. Each sample is measured at different temperatures to calibrate the color shift. The values measured in the laboratory are transferred directly to the production machine and used as a standard. This requires all instruments to have excellent inter-instrument agreement and long-term stability.

Stand-Alone or Fully Integrated to the Production System

Inline systems can work as a stand-alone device or be fully integrated into the Process Control System (PCS). In this case, the color measurement instrument is fully automated without any operator activity. As soon as a new production starts, the target is transferred to the color sensor and the inline measurement starts.

5 Steps for Controlling Color on Coil Coating

Using color measurement in the laboratory, on the production line, and throughout final quality control reporting helps manufacturers achieve consistent color faster and easier. Here are the five steps successful coil coaters follow.

In the lab, a laboratory spectrophotometer mounted on a heating table helps the paint and coatings supplier formulate and define the color standards. The standard is measured while using a heating system to show how temperature changes will impact the color.

After the color standard is set, it is shared with everyone involved in the workflow, including the supplier, workstations in the production control booth, at the color coating line, and at client sites, so each user has access to the same color data.

Once the coil coating process begins, inline color measurement systems continuously evaluate the color quality of the entire length and width of each coil. The traversing beam holds and moves the inline spectrophotometer in cross direction so it can measure while the coil is moving.

Results are shared in real time, so anyone in the network can monitor color quality and consistency. If a color tolerance is exceeded, graphics and alerts will make everyone aware before color deviations turn into a costly mistake.

The inline color measurement system provides complete documentation in the form of color quality records based on international standards to ensure the integrity of the program and customer satisfaction.

Conclusion

In a modern production process, all important parameters must be measured and controlled. Color is one of the most important parameters, as everyone will notice a difference on the product. While a measurement in the laboratory is necessary, the information comes too late for the machine operator. Only inline color measurements can help operators identify color shifts early enough to adjust the coating machine and produce high quality, consistent color.

Adding inline color measurement to the coil coating process has a typical return on investment (ROI) of six months. With automated real-time measurements during production, companies spend less time manually measuring strips, reduce waste, and save energy. Most importantly, inline color measurement improves overall product quality and customer satisfaction. RF

Manfred Binder is the Business Development director for Inline Color Measurement at X-Rite, the market leader for color measurement. He has 30 years of experience in the color measurement business specializing in inline applications across the paper, coil coating, plastics, textile, glass, and automotive industries.