Starting out as a tool and die company in 1979 in the town of Marion, Kansas, Marion Manufacturing has been involved in many markets over the years. They include manufacturing components for Coleman, Rubbermaid, acid machines for batteries, items and trim for the automation industry and more. Jack Richmond and his wife Joyce were the founders and they were very inventive.

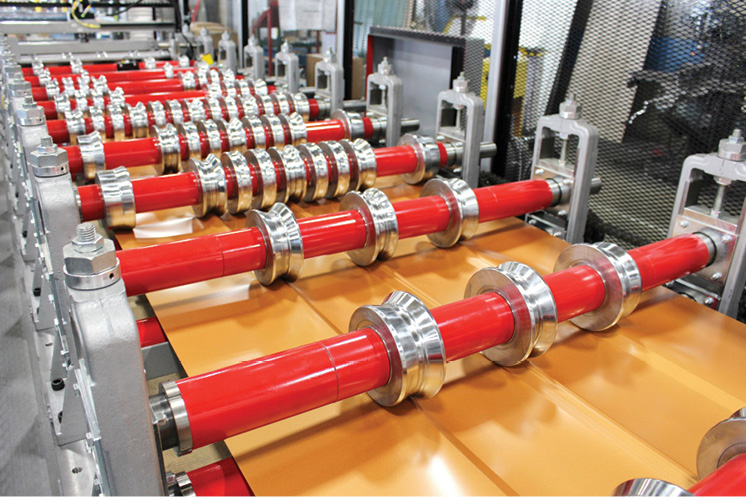

In 1992, a friend in Texas asked them to build him a roll-forming machine. Since then, they have been building machines in this niche including panel roll forming, trim roll forming, coil handling, controls, shears and more.

The first machines they built are still running today according to Tim Richmond, part owner along with three siblings who purchased the company from their parents 20 years ago. The company grew through word of mouth he said, as people saw that they built good, solid machines.

“Our machines are the Chevrolets of roll forming, not the Cadillacs,” Richmond said, “because they are more economical and still produce quality work after all these years.”

Marion Today

Roll forming machines are 75% of what the company fabricates now. They also make shear blades, slitter blades, and products for adjacent industries. They supply all the U.S. and Canada. Along with machines that display great longevity, the company delivers great customer service to all their customers. They serve roofing contractors, post-frame contractors, do-it-yourselfers, mom and pop panel shops, and big corporations, too.

Employee collaborate.

The friendly culture makes

work more enjoyable.

Challenges, Solutions, and Opportunities

Richmond finds that the biggest challenges come from the automation aspect of their work. It is hard to find engineers, electricians, and mechanical tradesmen to pull it all together. They have worked with outside vendors, groups that do electrical engineering. These engineers are hard to come by because they are so in demand; Richmond said everyone needs them.

The company now has 25 employees, and the majority of them were hired and trained into their roles. Many of their key positions have been filled by people who worked their way up. A great benefit package is part of what attracts people as is their culture, in which employees are a big group of friends, Richmond said. Everybody is friendly and believes in what they are doing.

They have company events; often Richmond makes everyone biscuits and gravy, and during the winter months, employees take turns making a pot of chili nearly every week, so they get to try a variety of recipes.

The company is located in a rural community, many of the employees are friends, and that spirit of comradeship and helpfulness permeates the work culture as well.

Richmond said that he learned to lead the company through the school of hard knocks. One of the things he has realized over the years is that a good documentation system can help any company. Document processes so that if someone leaves, the process doesn’t leave with them. Document meetings so everyone is clear on the outcome and what the plan is. Document everything; it doesn’t take much time as you go, and it can save a lot of time in the long run.

Cross-train more employees on various processes so that when an employee is out for the day, it doesn’t mean work comes to a halt or quality goes out the window.

“The more everyone knows, the better. Get people out of their comfort zone and give them opportunities to learn other things. They become more valuable, the company is better for it, and they may even think of a great improvement. Never be afraid to learn something new,” Richmond continued. “It’s a good day when I learn something new.

The Industry

“Currently we are quoting 18-month delivery on new machines, compared to our usual 6-8 months, and we are quoting new machines every day. Demand is high,” Richmond said, “and it looks like it will stay high for at least the next three years. There are so many people starting in the industry and a lot of older machines are being rebuilt.”

Richmond said he is not worried about new tariffs affecting the industry negatively. Some tariffs are already in place, and while they buy as much American made steel as they can, tariffs haven’t slowed business down so far.

“The costs of materials never really go down,” Richmond said. “Materials go up, then flatten. Then materials go up, then flatten. It’s about twice the price since the COVID-19 era and it hasn’t stopped anyone from roll forming or building.”

Marion’s goals are to keep growing, to keep making good equipment and to keep helping their customers to keep on rolling. RF