Being able to gauge trends within your own service area, and being nimble enough to capture those trends in time to make it pay off, is critical. While you need to be able to focus specifically on your own market base, here is a general look at current trends, both in and out of the shop.

Acu-Form,

Millersburg, Ohio

Metal panel with a standing seam look, and corrugated panel, have gained in popularity for interior use, Acu-Form reports. It’s being used in residential and retail spaces for wainscoting and ceilings to infuse an industrial or rustic mood to a room. Once standard in 2-foot panels, it is the 36-inch panel that has gained a foothold.

Ag panel is changing as well. “There used to be just one ag panel out there,” Wayne Troyer with Acu-Form said. Rib changes, a higher minor rib and a lower major rib, offer a stiffer panel.

Coming back in demand is one of the oldest panels for residential — the 5-V crimp exposed fastener panel. Demand is also noticed for pencil ribs on trim, which helps to hide imperfections.

As for customers of roll-forming equipment, Troyer said returning customers currently out-number industry newcomers, “people upgrading their equipment,” he said.

Returning customers account for about 75 percent while new startups are about 25 percent.

The Market

Acu-Form has a strong foothold in the agricultural panel space and has seen a bit of softening this year. Farm construction in the area has been aided by the shale industry, used for fracking oil and gas. “We’ve seen a strong impact in Ohio, Pennsylvania, into West Virginia [the Marcellus Shale area]. The farmers in these areas were booming because they had all this money to spend. Now they’ve got some of their money spent, so we’re seeing the softening,” reported Troyer.

Agriculture prices are a mixed bag, which also affects the panel industry. “Grain prices are going up a little bit, but milk prices, dairy prices, are coming down.” Crops are coming in late this fall due to a rainy spring, so grain prices will continue to be a question mark.

Despite the softening, Troyer doesn’t see any major decline or long-term impact. “I still think there’s a lot of market share to gain. I see it leveling off, but I don’t see it making a big dip. Come next spring, around April, we’ll likely be booming again.

Bradbury Co.,

Moundridge, Kansas

The Bradbury Company has seen four different trends in the roll-forming industry as suppliers look for methods to separate themselves from the competition by offering unique panels.

#1: Corrugated panels are gaining popularity. “Deep (7/8”) corrugation panel usage is growing as architectural features for roofs and walls,” the company reports. As well, “Shallow (1/4”) corrugation panel usage is growing as an interior decorative feature for walls, counters and other decorative features.”

#2: Machines that provide the ability to produce a usable panel with questionable material are continuing to gain market share. The company explains, “For example, a tool set that provides an overlap bead on an industry-standard AG panel allows material with a wavy edge to be produced.

“Another example is a tool set supplied with a bow correction fixture that allows AG panels to lay flat, which is a more aesthetic-appearing panel and a tighter lap without the use of stitch screws.”

#3: Trim machines that form basic and complex trim shapes are continuing to gain popularity. “A roll-formed trim product is more consistent, less likely to have forming damage, requires significantly less labor and does not require skilled labor when compared to a press brake or hydraulic trim folder,” Bradbury advised.

#4: Automated stacking and packaging solutions are a hot topic now, “mainly due to lack and/or cost of labor.”

The Market

The lack of skilled workers still poses a problem for roll-forming companies, as it has with other segments of the construction industry, with companies facing lots of work despite a “super-wet 2018 winter, super-wet 2019 spring, and coil price swings due to tariffs.”

Metal Rollforming Systems,

Spokane, Washington

As roll formers try to differentiate themselves from the competition, more are looking to introduce custom profiles. Metal Rollforming Systems is seeing this trend, particularly in corrugated and architectural profiles.

“The ¾” – 5 rib agricultural panel, everybody has that and it’s a commodity right now,” noted Bill Griffin, MRS. “People will try to buy it for the lowest cost possible. Our customers try to combat that by trying to come up with new profiles that only they offer and provides a designer look.” A customer recently commissioned MRS to design a concealed fastener panel with a board and batten look. This paired with advances in the metal painting process, specifically wood grain paint create a very attractive and very durable product.

Griffin sees a growing interest in wood grains and special colors. “Some of the textured, flat gloss-paint coatings, not the high gloss you’re used to seeing, is going to continue to open up new avenues for metal,” he said.

Cutting trim is more labor intensive, so to get away from labor demands, trim machines are replacing folders. “Labor costs are high, so when you are able to offset labor cost with capital equipment purchases, and you can get a machine that shows up every day and doesn’t get sick, doesn’t have emotional feelings, that’s been a big driver,” Griffin said. It also moves the needle towards more automation, which Griffin sees coming.

With asphalt still the leading form of roofing, Griffin says there’s nothing but room for growth for metal. “But it takes ingenuity and working with customers, with builders, with contractors on different ways and applications that the materials can be used. There’s a big push right now, so there is lots of room for growth.”

The Market

Griffin said the roll-forming industry has been very strong for several years. “We’ve seen growth year over year since we’ve started 26 years ago,” he said, adding: “The last three or four years in particular growth has been great.” While he said the “tariffs shook up the steel market for a little while, everything has now settled down.”

The biggest problem with the industry is a common theme: finding and keeping quality employees.

New Tech Machinery,

Denver, Colorado

New Tech Machinery is reporting more interest in their wall panel profiles, specifically their 1-inch and 1.5-inch flush wall/soffit panel. This popularity seems to be driven by calls for materials lighter than stone, brick, or concrete, and something low-maintenance and weatherproof.

Going hand-in-hand is increased demand for the company’s portable wall panel machine.

Other popular panel profiles include their 1.5- and 2-inch mechanical seam; 1.75 -inch snap-lock; and 1- and 1.5-inch fastener flange.

The Market

New Tech Machinery had a banner year in 2019. “We saw substantial growth, due to the increased demand for the use of metal in construction and architecture,” a spokesperson said.

“We expect to see continued growth in 2020, as our industry sees a demand for affordable, low-maintenance and quick solutions in metal roll-forming, which we can offer with our portable roll-forming machines.”

Samco Machinery,

Ontario, Canada

Samco Machinery is a North American company developing roll-forming and material handling solutions for a variety of markets in 35 countries. According to Jaswinder Bhatti, Vice President of Applications Engineering, the company’s appliance and automotive markets have surpassed the construction lines in 2019. Construction lines were still busy, however, particularly for the production of equipment for larger steel and high-rise projects, stud and track, cee purlins and zee purlins.

Wall and roof panel equipment lines have not been as active as in recent years, with the exception of agricultural panel. Another active area has been grain bins. Bhatti also reported that there has been more interest in component lines.

Demand for automation

As Bhatti looks ahead, interest in automation is definitely on an upward trajectory.

“Whereas the customer before would say ‘I don’t want to spend the money on automation,’ that same customer is coming back to us saying, ‘I want a completely-automated machine. I want to have a machine analytics and monitoring system.” Bhatti said.

He believes the interest in automation is being partly driven by the difficulty in finding and keeping skilled workforce. “Automated machines help result in increased safety and considerably improved uptimes. The machine analytics and monitoring system provides real time machine/production feedback regarding the performance of the machine (up-time, down-time, number and sizes of parts produced, maintenance issues etc.). This data can be easily gathered, stored, and analyzed based on the customer’s need,” he said.

A back-bone for future development of machines is that they can collect and store the data so it can be used for training AI algorithms which can predict failure of the components based on patterns in the machine’s behavior. This information helps the companies coordinate a preventative maintenance schedule.

Look ahead for automation to help create machines that can more easily and efficiently handle multiple functions to avoid costly inventory, Bhatti noted. “Right now we have customers who want to make a one-off part. They want a machine that can handle automatically either just one part or ten parts,” he said.

Another factor affecting the demand for automation deals with the increasing speeds of material production. “I’ve been in this roll-forming industry for 35 years. Machines used to run 50 feet per minute, now they run 450-plus feet per minute.

“Machine changeover (changing from one product to another) used to take a day, now customers are asking to change in seconds. Samco Machinery has designed and manufactured roll-forming lines with part length/width changeover in 9 seconds,” Bhatti said.

Automation helps to keep the resulting production and inventory coordinated.

He concluded: “Basically people want to know on their iPhone what the machine made today, how much was shipped in, how much was shipped out.” RF

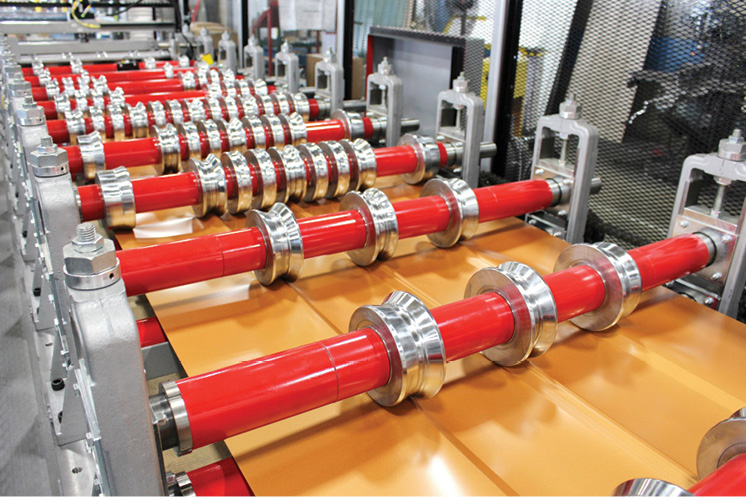

- Panel roll-forming machines have stayed busy, with automation a trend that is expected to increase as businesses have difficulties with finding and keeping good help. ASC Machine Tools photo