Uncovering Your Hidden Roll Former.

If you could produce more, could you sell it? If you said yes after reading the question above, congratulations! You are in position to significantly increase your revenue any time your metal forming machine is running. This is an enviable position indeed.

So how do you ramp up production to meet sales demand? One way to scale up: purchase more equipment, add another line and more staff. The line is producing well, demand is high. Why not add a line to boost production, and sell more? Makes sense. Does it really?

Can you really take on the capital expense of a large equipment purchase? Will sales be high enough to pay for the added equipment, let alone what it would cost to hire and train more workers? What happens if the market softens and demand decreases? Is there another way to increase production without the risk of a large capital expense?

The Hidden Roll Former On Your Plant Floor Is Hiding In Plain Sight

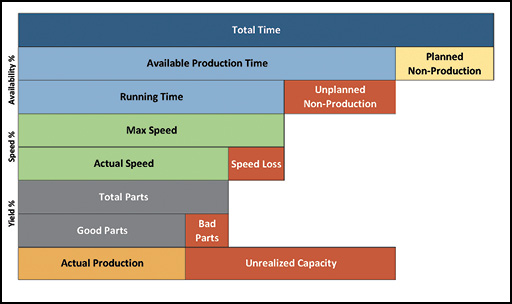

Overall Equipment Effectiveness (OEE) uses availability, speed and yield to help you understand how your equipment is performing.

Using OEE as a standard manufacturing measurement for equipment effectiveness, we can quickly determine if equipment is running at peak capacity. Without delving too deep into the mechanics of OEE measurement, OEE analyzes availability, speed and yield to provide a metric to measure the efficiency of a specific machine. The higher the percentage, the closer to maximum capacity the machine is running. Generally, most roll formers in the United States have an OEE of 20 percent to 60 percent.

TRUTH: If a piece of machinery has an OEE of 50 percent or lower, it is only producing half of what it could potentially produce. Which means you’ve found your hidden roll former!

Finding Your Machine’s True OEE

The first step to understanding the capacity of your manufacturing processes is to determine the OEE of your individual machinery. The process to uncover your machine’s true OEE starts first with benchmarking and the collection of reports to measure equipment availability, performance and output. The quality of these numbers are very important to ensure accurate benchmarks. As such, manual reporting that relies on operators to document run time, down time, changeovers and scrap are not reliable sources of good data. Whenever there is a human element required for the input of data, it’s impossible to expect accurate reporting.

If you are fortunate and have a machine controls partner that understands the importance of OEE and reporting, you are in luck! Machine controls are perfectly positioned to collect valuable data for OEE analysis, all without burdening operators with any manual reporting.

AMS Controls’ solutions provide the accurate reporting you need to not only benchmark your equipment, but to continually monitor and generate actionable data for your continuous improvement initiatives.

What To Do With You Benchmark OEE Numbers

Analyzing the OEE numbers of a machine quickly helps you identify bottlenecks in your processes. Bottlenecks could include issues such as coil changes taking too long, too many unscheduled maintenance and repairs or even high scrap numbers.

Once bottlenecks are identified, the next step is to determine the root cause of the problem. Accurate reporting is critical here to uncover the root causes of the problem.

An examination of downtime codes of the bottleneck in question is a good place to start. Of all the downtime codes listed, which are the most common? Which take the longest to resolve?

Which downtime, if solved, will have the biggest impact on productivity? Putting together a cross functional task force made up of both project managers and operators can help with the process of determining root causes and also devising solutions to reduce or eliminate bottlenecks.

OEE & Continuous Improvement

Can Do So Much More

If you want to know about the true capacity and effectiveness of your machinery, identifying the OEE of your machinery is an excellent starting point. Once the OEE has been identified, pairing OEE with your continuous improvement efforts can help you tap into the hidden roll former in your plant to improve not only your capacity, but ultimately your margins and profitability.

Plus, if your OEE shows your machine truly is running at capacity, you now have the documentation to prove and justify a capital expense.

There is a lot to discuss when it comes to OEE. Have a question on anything you’ve read? We’d love to hear from you. Drop us a note at [email protected].

This article was provided by AMS Controls, which has a complete production management system to optimize the manufacturing of panels, purlins, trim, studs and more. Since 1977, AMS Controls has sold 13,000+ controllers worldwide. Industry leaders have chosen AMS Controls’ complete production management system to optimize the manufacturing of panels, purlins, trim, studs and structural products.

Their solutions can be used with any brand of roll former or folder to effortlessly eliminate mistakes, manage coil inventory and track production. For more information, please visit www.amscontrols.com. RF