Ephraim Esch thought he would leave the demanding work of dairy farming and ‘semi-retire’ into metal forming. That was his first mistake. Now the busy owner of Solanco Metal Roofing LLC in Lancaster County, Pennsylvania, Esch has broken ground on a new building that will triple his current space established in 2014 and create a new opportunity in the other half of the building to open an accompanying lumberyard. His plans now — to never retire.

An interesting tidbit about Esch’s journey into roll forming is his lack of history in the industry. Most professional rollformers have some background in construction or metal fabrication. Growing up, Esch was involved in his share of barn raisings in his Amish community that involved installing metal, but otherwise he had always been a farmer. “When I think back, I think I must have been half crazy because I didn’t know anything about this industry,” he said.

He was first exposed to the idea of going into the panel-forming business when a friend in Wisconsin, already in the business, suggested it. His immediate reaction: not interested. Well, sort of. It did pique his interest. He began to investigate.

He sought out potential customers, cautiously at first. “I wasn’t talking directly to people but beating around the bush and smelling things out,” he said. Then he got bolder. “I knew quite a few contractors, a cousin of mine is a pretty big contractor in ag buildings, so I talked to him before I started and he said ‘yeah, I’ll give you a shot at it.’”

Other contractors also expressed interest, enough to be encouraging. “I’d meet somebody in the construction world, and I’d get to talking,” he said, “and there were farmers in the area who wanted to do projects and [would wait] until I was up and running.”

There were also many conversations with equipment manufacturers, coil suppliers, bankers, and other rollformers. After more than a year, he decided maybe it wasn’t such a bad idea after all.

He said he aligned himself with two companies that helped him navigate the treacherous waters of such a major journey: coil supplier Hixwood Metal, and machine manufacturer Acu-Form, both which answered his countless beginner questions.

His farm became his equity to afford the major debt he was about to take on. It would take him another six or seven months to finalize his plans. “I wasted so much paper and filled so many trash cans before I did this, it’s almost a shame,” he admitted. “I wanted to be very positive. I was a farmer all my life and farmers don’t necessarily get very rich, at least not cash rich.”

Esch cleaned out an unused 50×95 foot chicken barn on his farm to set up his initial operation. “If I had to build a building, it would almost have been a no-no for me,” he said. “Equipment is one thing but if you have to buy property and build a shop, then it becomes too much.”

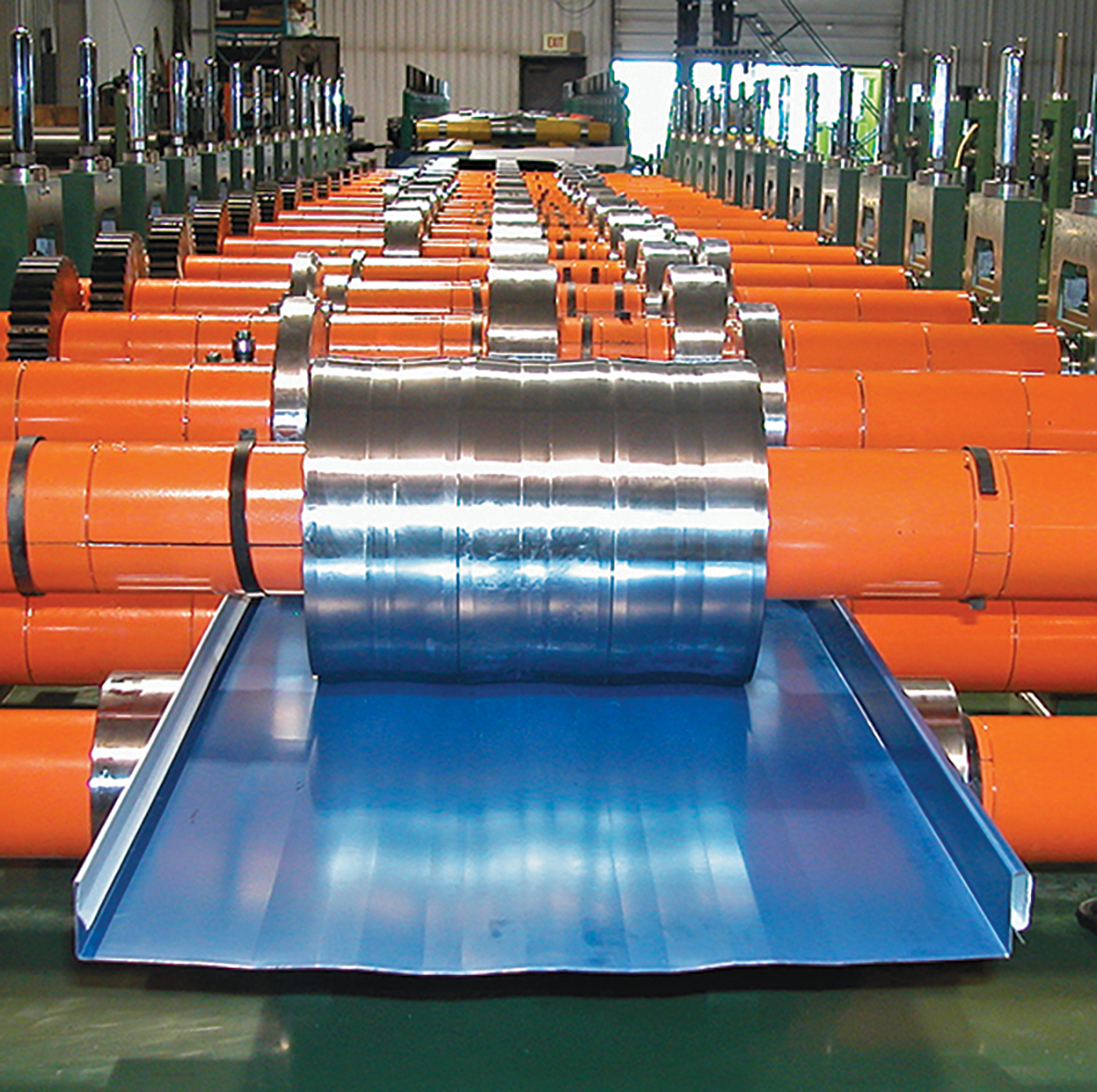

His equipment of choice included a new roll former for ag panel, and four trim folders from Acu-Form, all run on hydraulic systems. The roll former is equipped with a 12-volt control panel with a solar panel hooked to the battery to keep it charging. He also purchased a used Chicago manual brake.

With his three sons helping with the milking chores, he began his ‘semi-retirement’ into roll forming.

The early years

Esch worked alone for two years until he was established, then hired a full-time worker (he now has three). He stopped milking cows when he realized he needed more sleep. His oldest son took over the farm. About the only immediate reminder to the building’s past life are some free-range bantam roosters out in the barnyard. “I just love to hear them crow,” he said. “There’s no income, no nothing with them, they’re like a dog — you just got ‘em to have them around.”

Originally Esch was concerned that a major roll-forming company in his general region would make it difficult to find customers to buy his panel. In truth it was a non-issue as contractors were eager to find service closer to home from a company that could offer quick turnaround.

Sometimes, he admits, the contractors had to explain what they wanted. “I also had friends in the roll-forming business in Ohio and Wisconsin and I could talk with them. We got through it, but I’m not sure how it all happened.” He said if he knew then what he knows now, he would have shaken like a leaf from the overwhelming things he had to learn.

He credits much to “the Amish radio [word-of-mouth advertising in the religious community] for the success of Solanco Metal. “It has worked as well as you can find anywhere,” he quipped, noting that most of his customers are Amish contractors. He does no other advertising.

At first, Solanco panel was going primarily into ag buildings. “Ag was booming then,” Esch said; “2014 was a very good year for farmers.”

The ag market dipped, but fortunately Solanco’s growing reputation allowed Esch to make inroads in the residential and small commercial markets. Solanco is ideally situated for such markets, located near very populous areas. His contractor customers travel to jobs in Baltimore, Maryland; Wilmington, Delaware; and New Jersey. Lancaster County itself has a demanding consumer base. “People are pretty fussy here. They want a good product, so I decided if I’m going to do this, I’m going to do it right.”

Esch purchased additional equipment to cater to the residential and small commercial markets. Consulting again with Hixwood, he added a board and batten horizontal siding machine from Eastside Machine Co., a soffit machine, and a portable roll former for on site standing seam. The board and batten machine in particular was a good decision. “There was no board and batten done in Eastern Pennsylvania when I got this machine,” he said. “Paul with Hixwood called me one day and told me about it and I said ‘wow!’ So I worked towards that and got it up and running and it’s doing quite well.”

Lessons learned

Esch has learned many lessons along the way and repeats advice we hear often from other owners of roll-forming businesses; to survive and thrive in the business the No. 1 asset is good service.

Also important: a quality product and convenient location, the latter not very far off the beaten path and not far from metal-hungry contractors. “Price is very important, but it isn’t the most important,” he added.

If you are thinking about getting into the business, Esch cautions, “you must be sure you have a customer base. Talk to customers, is there a demand for it?”

If there is, be willing to sleep fewer hours to meet those demands. “Contractors don’t like to wait,” he said. “I’ve spent nights in here ‘til midnight. I’ve gotten very little sleep to prove I can provide service.”

Breaking ground on a new building

It’s been seven years since Solanco Metal Roofing has been in business, and like the seven-year itch, it’s time to grow it or leave it. Esch is about to grow it. Ground has been broken on a new 100×300 foot building about a mile away from the farm. A new lumberyard business, operating independently, will be in one area of the building, and Esch’s metal division in another. His reasoning for the lumberyard: “A lot of contractors around here want to make just one phone call for their wood and metal.”

A new folder is on Esch’s purchase list. Extra floor space will be used for trim inventory to meet demand.

Esch is expecting to move his equipment into the new building this coming January.

There will be someone else in charge of the lumberyard, while Esch remains at the helm of the metal-forming shop.

Reflecting back on his journey from farming to roll forming, Esch said, “I wanted to do this as a retirement job; well, it ended up being the end of farming and the start of working. I’ll probably retire the day I die.”

But don’t feel bad that his semi-retirement plans have gone awry. “I enjoy it very much,” he said of the roll-forming business. “Cows don’t beat you up like people do, but that’s fine. I enjoy it very much. It’s a very different world, but I enjoy it very much.” RF

Rollforming Magazine is planning to visit the new shop and show you the dramatic before-and-after photos upon completion. Look for the update next year.