Swaging To Allow End Lapping

When constructing large metal buildings, long roof panels are often required. If the necessary panel lengths exceed the available shipping options, manufacturers can run panels on site with portable job site roll formers. But another option available is that panels can be factory-swaged to allow end lapping.

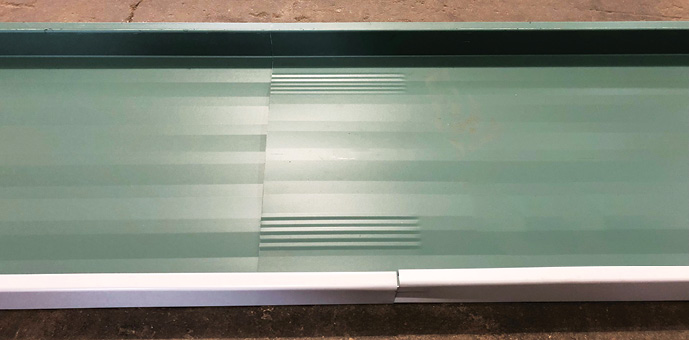

Swaging is the process of reducing the pan width of one end of the panel to allow it to slide on top of the next panel.

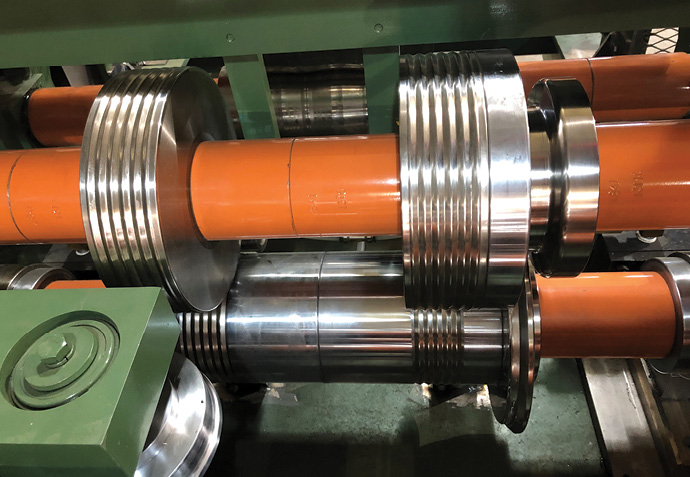

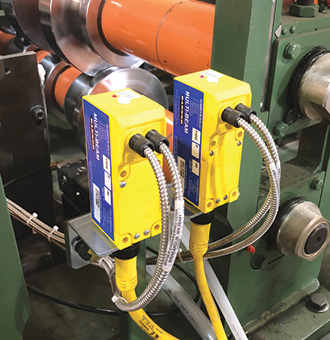

With Bradbury equipment, the pan is reduced by forming a corrugation pattern. Photo eyes sense the lead of the part and then activates a pneumatic cylinder that engages the corrugation tooling, resulting in a corrugation pattern that shrinks the pan by approximately 1/16th of an inch.

The smaller pan dimension allows the swaged panel to nest inside the standard-width panel.

Bradbury can also retrofit an existing machine with a swage system. RF

- Bradbury panel with swage

- Photo eyes sense the lead to start activation of the tooling process.