By Anthony Brass

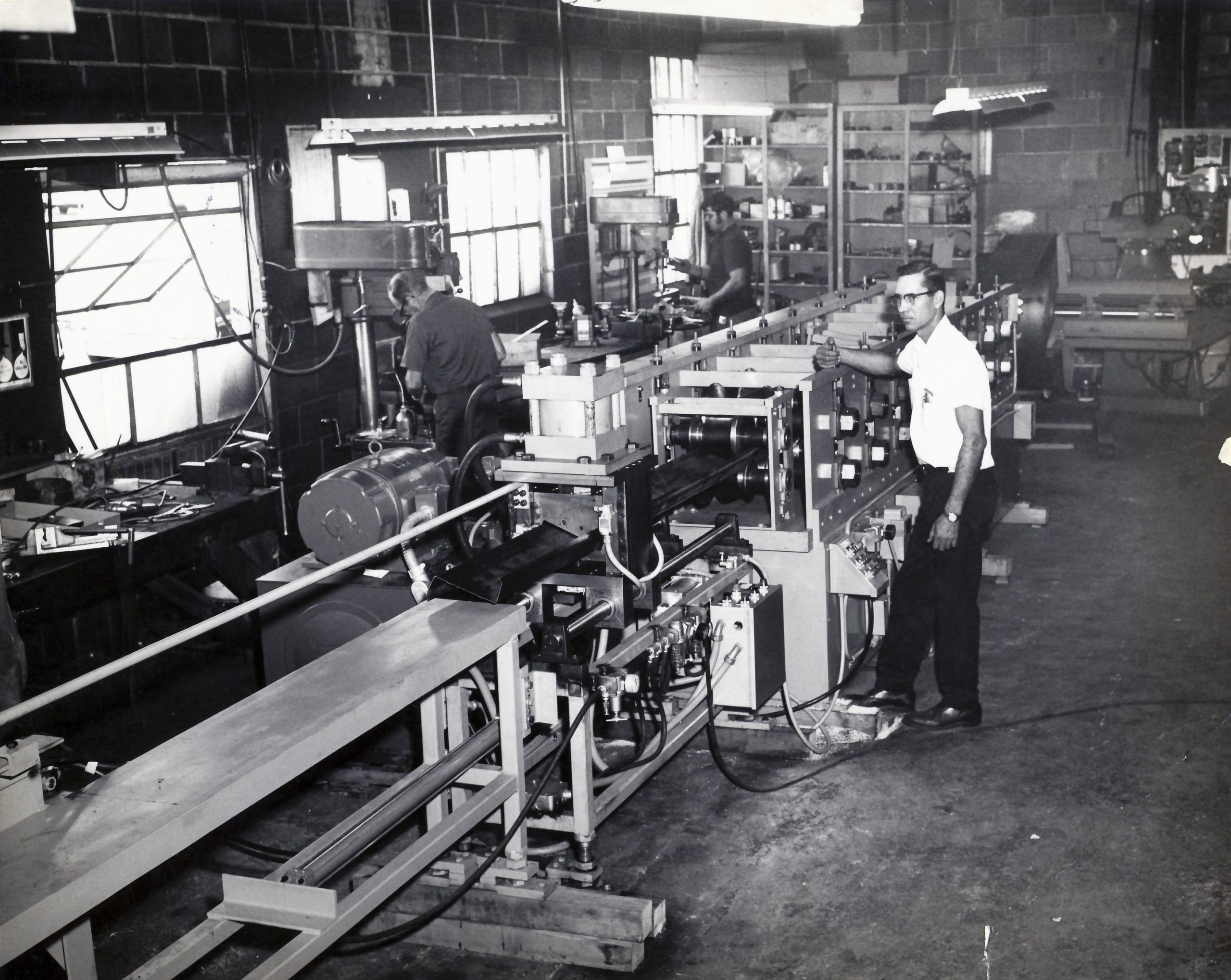

The Bradbury Group wasn’t always a “group.” The company started out as a custom roll-forming business in 1959 in Kansas. Floyd Bradbury and Jack Lacy manufactured awnings and other products, and roller die tooling for customers. They had humble beginnings, setting up shop in an egg room of a creamery. Early on, the company catered to the aviation industry, roll-forming parts for aircraft in Wichita, in addition to the Ag and transportation industries. One of the more notable orders in Bradbury history was supplying roll formed curved rings for the Saturn V rocket.

They designed more roll tooling and machines on their own, and opened up additional lines of industries, including metal buildings, which was crucial to their growth, says Senior Manager of Sales and Marketing, Matt Werner.

“That [metal buildings] is our largest industry every year,” says Werner, who has 18 years under his belt with Bradbury. Werner came on board in sales. He was in another industry, but Moundridge is a small town, and he heard from others the company was looking for help.

Today, Floyd’s son David is involved in the decision making along with his son-in-law, David Cox, who is CEO. They are all close-knit, and always think big in expanding the company.

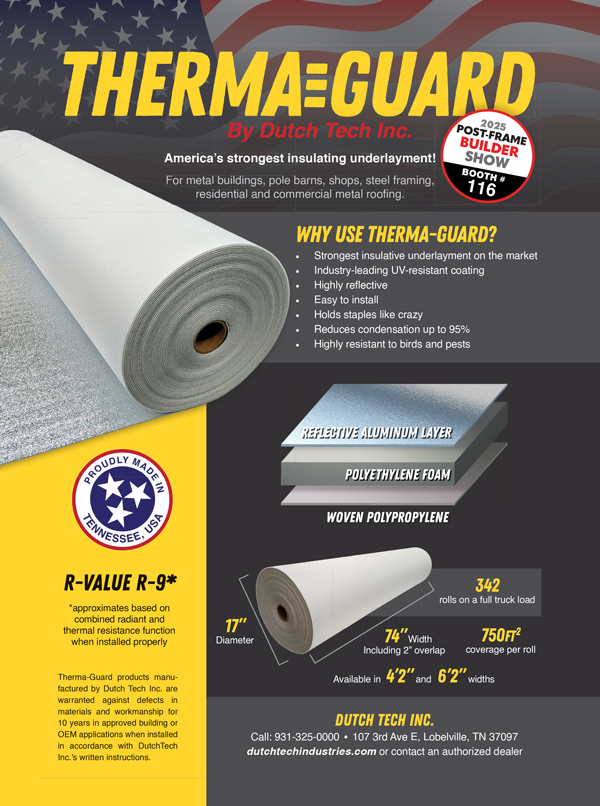

The family business is a leading global roll-forming and coil processing equipment manufacturer. They are innovative, holding over 28 active US patents and 60 international patents for equipment. They produce machines for metal buildings, garage doors, HVAC, grain storage, steel framing, transportation, automotive and more. The Group has equipment running in 89 countries. They continue as stalwart leaders in original equipment manufacturing of metal forming, parts production, coil processing, and polyurethane equipment along with automation and shop floor integration software.

Garage Group

Over 20 years ago, the company built its first fully automated garage door roll-forming line. Some components of that line were supplied by other manufacturers. Werner says over the years, through expansion and acquisitions, The Group was able to become a single-source provider of complex roll-forming lines. Currently, The Bradbury Group of companies can supply a turnkey solution for customers needing custom-built production lines. Embossers for garage door lines are now supplied by Alliance Machine and Engraving, a member of the Group. They’re perfect partners to join the company with their metal, plastic, and film embossing machines for products like composite decking and siding. The addition of Bradbury Group Pu.Ma. gives them the ability to manufacture continuous, foam-filled panel production lines for the garage door industry and numerous others.

When the demand for advanced controls and automation increased, Bradbury formed Beck Automation to bring the most up-to-date controls to the industry, Werner says.

These and subsequent moves echo the company’s vision of earning the title as, “the most trusted and preferred supplier in the global markets” they serve. Their growth is truly international and expands their base.

TRAINING DAY

The dynamic lineup of productivity-enhancing roll-forming equipment is designed to cover many applications. This makes for a diverse customer base ready to do business with the Group. They generate sales through word of mouth and reputation. Many potential clients come to their Moundridge headquarters to collaborate with the Bradbury engineers and roll-forming experts and observe the machines in action. “In the end we will configure a line that fits their production needs,” Werner says. “Once a machine is designed and assembled, we will operate the entire production line at Bradbury to ensure it meets the customer’s expectations.” Their clients are encouraged to come in for both training and the buy-off process of that line.

“For a new piece of equipment, that time frame will vary based on the complexity of the machine from a few days to a few weeks.” Werner adds once the line is approved and bought-off, they disassemble and ship the equipment to the client’s facility. Installation and startup of the line is performed by Bradbury’s team of Field Service Technicians followed by operator training.

One of Bradbury’s most popular offerings includes their state-of-the-art, high-speed, closed-loop flying B.O.S.S. ™ shear line for feeding panel roll formers. These are much sought-after with their ability to increase productivity of a new or existing roll-forming line. Their Cee and Zee purlin roll forming lines are also in high demand, driven by a strong building market and the need for highly productive lines that can be operated by a minimal number of operators.

AUTOMATION NATION

“Labor shortages in our customers’ industries are driving the integration of robotics and higher levels of automation,” Werner says. “It [automation] fits right into the equipment that we build.”

The company has delivered lines with integrated robots that can feed product to the rollformers and stack finished parts at the exit of the line, reducing the number of needed operators.

Bradbury rolls on as a leader in providing innovative equipment and opportunities to clients. They grow with partners and help businesses large and small with their equipment solutions. The Bradbury Group is not unlike their machines they build — strong and consistent with results to grow. They’ve come a long way since running those purlin roll formers in that egg room in Moundridge. RF