Story and photos by Sharon Thatcher

“Not everyone likes vanilla ice cream” sums up Ryan Schroer’s business philosophy. As he expands his metal roofing and roll-forming businesses under the name Western Ohio Metal Roofing, based in Sidney, Ohio, he looks for additional products and services to cater to diverse customer palates.

Ryan started his career in metal roofing on the crew of a local contractor that installed high-quality stamped metal roofing products manufactured as Classic Metal Roofing Systems by Isaiah Industries in nearby Piqua. Even after Ryan started his own business in 2006, metal shingle products (tile, slate, and asphalt lookalikes) were his bread-and-butter.

As time passed, however, the growing popularity of standing seam to a different set of customers, who wanted the benefits of metal but at a lower cost, was an option he couldn’t ignore. He expanded by offering standing seam, with his roll-formed panel also sourced from Isaiah Industries.

Rising steel prices during the Covid years threw everything out of kilter. The price of a new metal roof, be it shingles or panel, was escalating. More people were opting for panel, so the question for Ryan was: “How can I keep prices to my customers where they are now, or even lower? I need an edge on my competition and I need it now. When prices are going up for everyone, how can I differentiate myself by being lower than that?”

Earlier in his business he made the mistake of keeping his prices low at his own expense. Lesson learned he sought other answers. He opted to do more of the work himself and cut out the middleman. He went full bore and purchased a complete metal fabrication shop with a CIDAN shear and CIDAN XF folder, then added his first New Tech SSR portable roll former. He was now in the roll-forming business. “The leg work behind [the process of buying panel from a supplier] can’t compete to what we’re doing now,” he said.

That was three years ago, and every job is justification for his action. “It’s becoming more and more efficient every day. Every year my business has increased by production and sales about 40%, and that’s for the past several years,” he said.

Advice

When Ryan went into business he said, “the main reason wasn’t money, it was just wanting to work for myself.” It hasn’t been easy. “Every single lesson has come with a very steep price tag,” he said.

If advising a newcomer to the industry he offers: “I would probably suggest education on bidding … because you get yourself into serious problems with underbidding; you’ll find yourself putting on a roof and at the end having no paycheck for yourself.”

He also suggests seeking professional advice on business, and networking with as many people in the industry as possible as you grow to set up a strong business foundation and to find quality help. “We’re growing, and just by growing more, and taking advice from great people that I’m able to talk to, I’m able to implement the right people into my practice,” he said. His crews can carry on without his constant supervision, which, he maintains “frees me up to do more sales, and our sales go up.”

Expanding Options

Ryan’s crews are willing to travel for work to all parts of Ohio and are trained in every product Western Ohio Metal Roofing offers, which still includes Classic Metals shingles, plus standing seam, and even asphalt. Currently, however, standing seam accounts for about 80% of business.

Offering every ‘flavor’ of roofing provides great talking points for Ryan as he speaks with potential customers. He explains the typical conversation: “Most homes I enter, I honestly find most husbands are after standing seam right away. And the wife has already determined that she does not want the ‘barn look.’ One of two things happen during that process: She learns how modern and sleek the standing seam roof of today can look, or she still doesn’t like it and we explore metal shingles.”

The customers finally opting for metal shingles are “usually business owners or folks with two disposable incomes, house paid for, and they’re well set up and ready for an investment-grade roof.” In Ryan’s territory, those customers do exist, so he likes to have that option available.

But for most customers, the cost differentiation drives them back to either metal standing seam, or asphalt shingles.

He doesn’t believe in forcing the issue, realizing that not everyone’s house adapts well to just any roof style. Although he likes the modern standing seam look, on his own home he chose Country Manor metal shingles from Classic Metal.

Most of his customers are trying to get away from asphalt shingles entirely because they do not hold up well in the windy conditions Ohio can present. “We’re really windy,” Ryan said “and consumers are finding out now that they replaced their roof previously and they’re only getting 8-10 years before they need to get it replaced. What they thought was a 30-year roof, isn’t; it’s blowing off a lot sooner.”

In metropolitan areas, solar can be a deciding factor. “A lot of homeowners are looking for metal and they are also looking for solar,” Ryan explained. “With standing seam, solar panels just clamp right onto the roof without any penetration.” He partners with a solar installer who uses pinch clamps with set screws. The huge benefit is that the roofing warranty can be maintained in whole. With any other type of roofing, the solar panels need to be bolted through the roofing material, voiding out warranties.

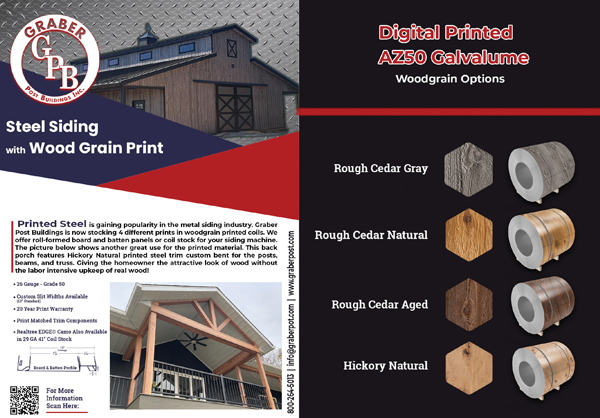

Ryan said his most popular product is 16” concealed fastener standing seam, 26- and 24-gauge metal with PVDF coatings. He sources his coil from CMG and Sheffield. Browns and grays are currently popular colors.

The Future

Ryan’s work trucks bear the name Schroer & Sons, offering a good indication of the future direction of the company. His two college-age sons are planning to continue the family business in the years ahead, giving Ryan reason to continue growing the company.

In six months to a year, he plans to add a second New Tech SSR so he can worry less about scheduling his three crews around just one. Although the SSR is New Tech’s introductory model, Ryan says it does everything he needs it to accomplish. “It’s a fantastic machine, and very user friendly.”

The second portable roll former will also allow him to offer chop-and-drop service “because there’s a lot of contractors that have no interest in the financial investment in the equipment, but they’re very interested in getting material easier, faster, and cut to length,” he said.

He is also looking to expand the company’s physical footprint. Currently leasing warehouse space, Ryan is making plans to own a warehouse.

Farther into the future, who knows? Ryan knows that even in roofing and roll-forming, there’s lots of flavors of ice cream. RF

Sharon Thatcher is the former managing editor of Rollforming Magazine. She is now an independent writer living in Ohio.