Getting Started

In those days, back in the ’90s, lead times on custom-manufactured metal roofing in the local area were 7-10 days. Understanding that reducing that lead time would have a significant impact on project completion time and profits for the contractor was the epiphany that moved Marvin Ramer forward in 1999 and Ramco was born.

A building contractor, frustrated by long lead times, delivery delays, and incorrect shipments, Ramer decided to do something about it. By April 2000 he convinced a large manufacturer to provide him shipments multiple times a week to supply the local Ramco customers. Between this service and diligent customer care, within three years, in 2003, he was one of the top resellers in the area. He started his own manufacturing business out of a small shop at his home with little funding. But he had three important goals: providing accurate orders, faster lead times to customers, and running a well-grounded company.

Ramer started with two new trim machines: a 10’ Schechtl trim machine and a Metal Rollforming Systems (MRS) Titan roll former. “I was always interested in machinery,” Ramer said, “and the learning curve for adjusting roll-forming machines to make a high-quality panel was complex but fun. I chose new machines because quality has always been our focus. The quality of the machine has a definite impact on the panel quality.”

By leasing the building and the machines, Ramer started with basically no money but plenty of passion, grit, and determination. From those early years, Ramer made a point of reinvesting most of the profits back into the company and always holding the line to only grow at the speed of profits. Running the company with such careful attention to financial health translated into top-notch customer service. His rule is that you do the right thing every time, and if it means you take a hit, you take the hit. He has always gone the second mile for his customers, and the result has been company growth.

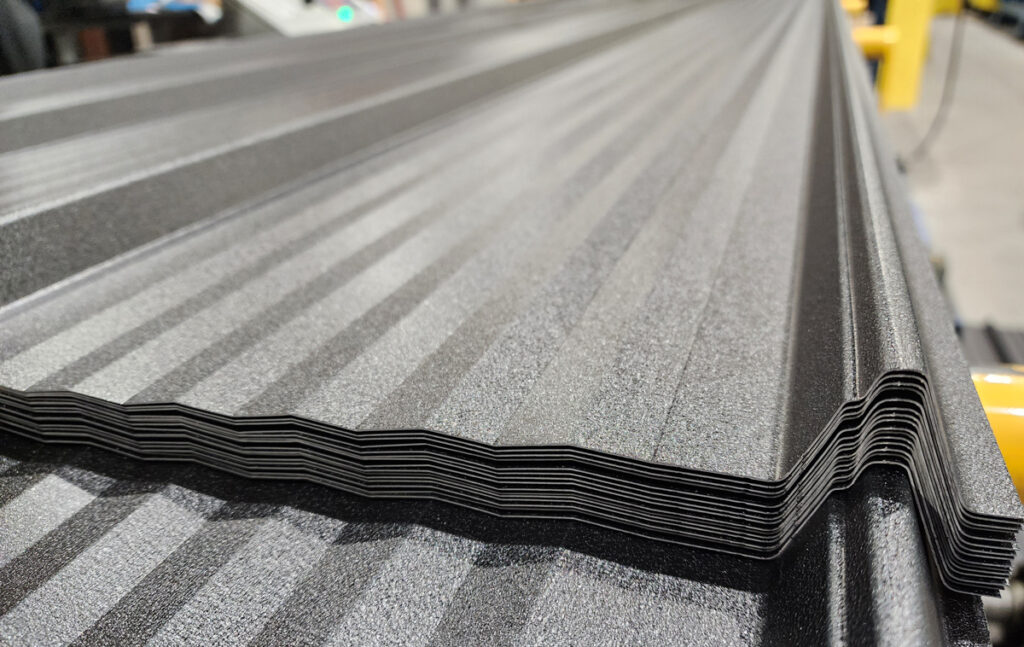

Ramco’s RX-4 panel. All photos courtesy of RAMCO

The Middlebury, Indiana, facility.

Ramco’s original facility.

The Rochester, Indiana, facility.

The Woodburn, Indiana, facility.

Growth

Over the years, Ramco has steadily grown—from the first small building to small building add-ons and then an additional building, expanding into a new location and new facility in 2011, and eventually opening a second location in Woodburn. Now, with nearly three decades of growth, Ramco operates three locations across Indiana: Rochester, Woodburn, and Middlebury. The company now sells across the Midwest, throughout Indiana, Illinois, into Ohio and Michigan.

This growth has often been attributed to operational excellence — a term often heard at Ramco. It’s more than just a sign on the wall; it translates into things that customers care about like: most deliveries in under 24 hours, thicker steel, an abundance of inventory, state-of-the-art Bradbury high-speed metal forming equipment, and, of course, people who want to help serve and have bought into the vision of a profitable well-run company. It’s good for all involved.

Their facility is kept very clean. That contributes to equipment that works well and provides a quality work environment. They go as far as hand scrubbing machines with soap and degreaser. “Just like my personal truck, it always runs better when it’s clean,” Ramer added.

The company produces 11 profiles of metal roofing and siding panels. These include Ram-Panel, two standing seam profiles, Commercial “PBR” and “A” panel, Modern Plank, Metal-lap, Board & Batten, and Ramco’s RX-4. The RX-4 is now popular in the industry, but originally, in 2014, it was a unique, market-leading design by Ramer. The company also produces various trims and custom trims.

“We are continually considering how to make life easier for the contractor on the jobsite or up on the roof installing the metal,” said Ramer. As a result, the business has grown from a “one-man-band” to a busy company of 130 employees.

Ramco Today

Commercial, agricultural, and residential buildings plus roofing for single family and multi-family homes, sheds, and garages are all markets that the company serves. They sell to lumber yards and do-it-yourselfers, but contractors that build metal ag buildings and residential house roofs are always the center of consideration.

“Customers like our contractor-first mentality,” Ramer said. “They care about price, but that is not the be-all and end-all. We are not the cheapest, but customers come back to us because they know when they call they will get a person, not an automated voice system. They know they will be speaking to someone who knows the product and they will not be transferred somewhere else. And,” Ramer finished, “they know their order will be delivered quickly and accurately.”

2024 has been a good year for Ramco. “We have not seen a cool-down. Ramco is growing. We’ve added a location in the last two years, and we are now expanding it. We are also expanding the Rochester location, and we just finished an expansion in Woodburn.”

Across the industry and beyond, companies are finding that retaining good employees is a challenge. However, this company finds little difficulty in retaining its employees. Josh Hudgens, Director of Human Resources, believes this is largely a result of the company culture.

“We have a strong company culture that focuses on a clean, family oriented atmosphere,” Hudgens said. We advertise on Indeed that Ramco is based on conservative Christian values, and we try to make the company a productive and happy place for people to come and work. We have occasional events such as fun nights, Christmas parties, and employee cookouts. But I think most of all people are happy to work in a positive, clean environment,” he added.

Coming in 2025

Ramer expects to see growth over the course of the next year. He looks to continue growing Ramco‘s footprint in the Midwest. Ultimately, they make decisions based on the contractors and how they can best serve them. RF