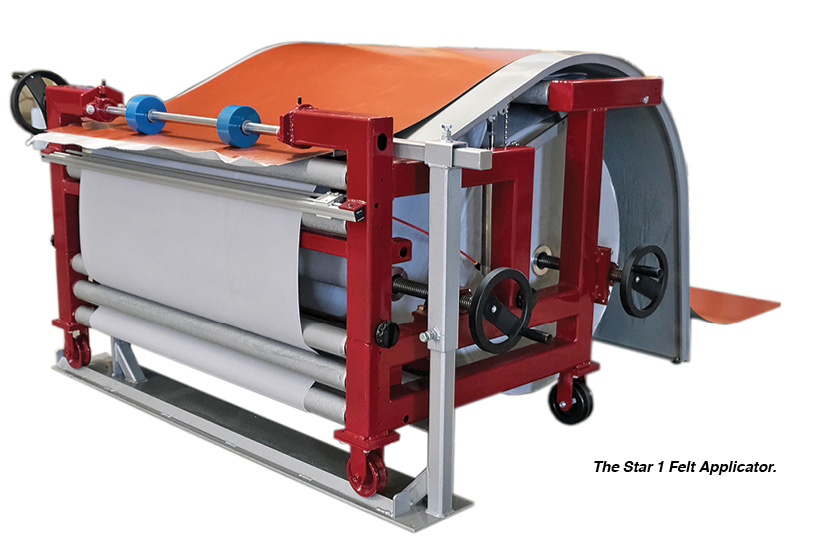

Star 1 Felt Applicator Designed to Improve Condensation-Control Application

By Sharon Thatcher

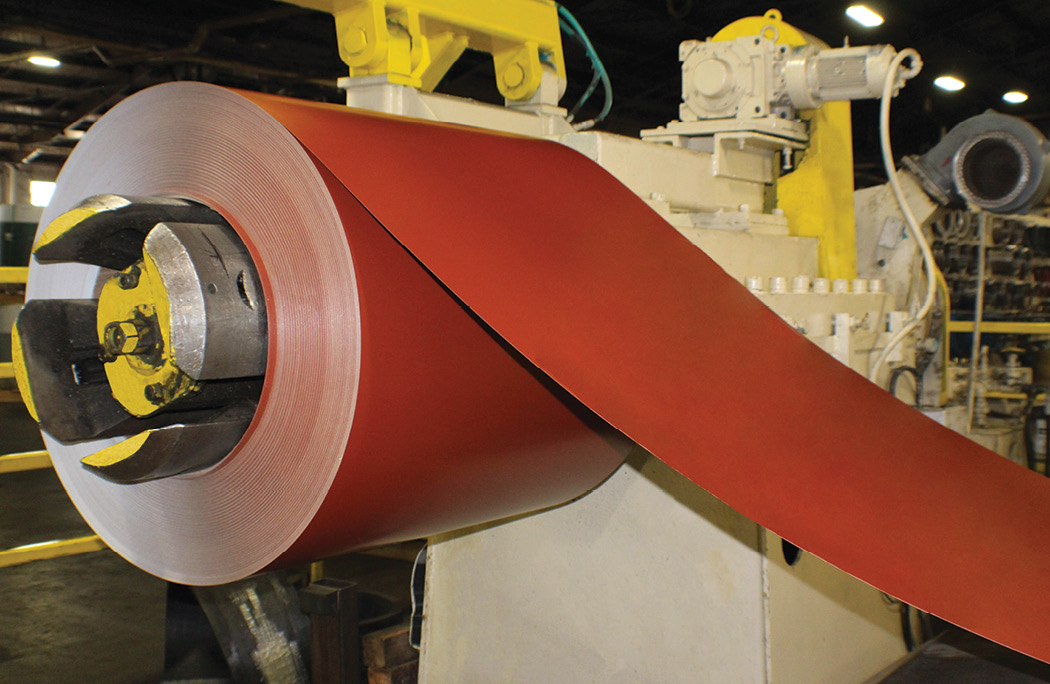

One of the greatest things to happen in the insulation, moisture-control industry is the development of felt products designed to be directly applied to metal panels. Used primarily in un-insulated buildings in agricultural construction, products like DripStop, CondenStop, and TearStop have eliminated the installation steps needed by roofers because the felt is applied by roll formers directly to the panel. When done correctly, the end result is a building that is protected from the damaging affects of moisture.

Although these felts are simple peel-and-place products that are very effective, some roll formers have reported problems with applying the felt to metal. In some cases, backing on the felt comes off inside the machine rather than, as intended, before it goes into the machine, gumming up rollers and dies. A steel fabrication shop in Michigan made it their goal to find a solution.

Brothers Nelson and Robert Miller of McBain, Michigan, developed the Star 1 Felt Applicator, designed for use with any felt brands, and on any standard panel roll-forming machine.

Nelson explained that the idea was prompted by Royal Oaks Metals, a roll-forming company in their neighborhood (see the Summer issue of Rollforming Magazine for more about Royal Oaks).

“My brother, Robert, was involved in helping them develop this new applicator with the new features for easier application of the felt,” Miller said. “They told him what they were looking for and from that we designed the machine and kept improving on it.”

In addition to wanting a way to pull the backer off more consistently, also on the wish list was a left-to-right adjustment that would more accurately place the felt on the metal, plus an easier way to splice two felt rolls together.

When other metal suppliers in the area heard about it, they were interested and started ordering. The felt applicator was developed in early 2018 and placed in several roll-forming businesses by mid-2018. The businesses provided feedback that helped to improve on the final machine. They also made the Millers aware that there was a larger market for the machine. It measures 60 inches in length and 56 inches wide and goes between the uncoiler and roll former, bolted in place by six floor anchors.

The Miller brothers are now preparing to introduce it to the market under the company name Star 1 Products LLC.

Plans are already underway to build various models that accommodate different customer needs. “The shops we were first working with were smaller shops, and they were looking for something they could leave in place; when they’re not applying the felt, the metal just rolls over the top and stays out of the way, right where it’s at,” Nelson said. “But other shops want to be able to roll it out of the way. Those are things we’re working on to improve.”

They are also now working to develop a more compact machine for space-challenged shops. RF

For information call 888-96-Star1.

- A knife guide squares off your felt.

- New roll being spliced together.