Small slitters are fine if you don’t have a large trim volume, but they just don’t cut it for roll-forming businesses with high-volume needs or plans to sell slit coil to other companies. If your business is in or approaching either category, it pays to look at a high-volume slitter line. The decision then is whether to choose a manual or automatic machine.

The Evolution of Slitting

Slitters have been around in some form or another for many years but have seen a myriad of advancements as the industry continues to evolve. They began as manual machines, meaning that the operator had to manually make all the necessary sizing adjustments to the machine prior to cutting. Unfortunately, operator error resulted in wasted product when the blades were not set correctly, or parts were not nested in an efficient manner.

Another disadvantage was safety as the operator was open to injury while making those manual adjustments.

Marxman SS1220 Manual Slitter

Manual Slitters

Manual slitters have improved and, because they are less costly, still very popular today. SWI Machinery is dedicated to the larger-volume slitter line industry and designed their manual Marxman S1220 and SS1220 based on industry feedback and improved technology. According to Jason Smoak, Sales Engineer, the machines can be integrated with the same software technology as SWI’s more expensive automatic Marxman Plus and Marxman Pro. This integration allows for automatic part nesting to ensure minimal waste.

Added as well are safety features, such as remote control of the machine and safety switches that do not allow for operation while the doors are open.

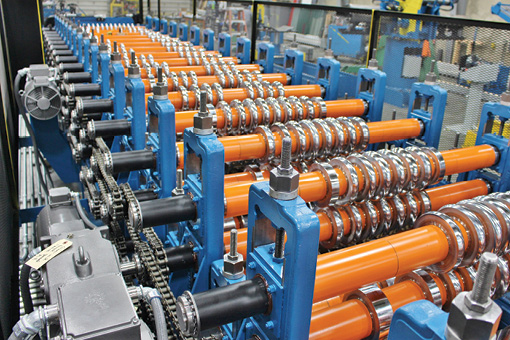

Marxman Pro Automatic Slitter

Photos courtesy of SWI Machinery

Automatic Slitters

While technology has helped to make manual machines more desirable, you can’t beat an automatic slitter for the highest level of accuracy. Automatic blade set-up greatly reduces incorrectly cut parts and wasted product.

That efficiency is particularly important as steel prices increase, noted Smoak. “There is little that an operation can do to counteract the rising prices of materials, largely steel, right now,” he said, “however, what we can help operations control is waste production. The increased accuracy and advanced operating software (allowing for automatic part nesting even between multiple jobs and coil management so you know exactly how much material you have at any time) of an automatic slitter ensures your operation can run efficiently and cost effectively.”

While operator safety has been enhanced for manual slitters, greater safety is achieved with an automated slitter as there is no need for operators to have their hands in the machine during any part of the setup and changeover processes.

An added plus for automatic slitters is labor. Said Smoak, “Across the industry, finding workers is becoming increasingly difficult and keeping them on staff even more so. Automatic slitters require less time to train, saving you money, and they require less experience so the need to find ‘qualified labor’ is diminished. When we deliver a new machine at a facility we can have the machine installed, operating, and all staff trained on how to independently operate it within 48 hours.”

SWI uses Team Viewer to troubleshoot software issues remotely and schedules a service visit when hands-on assistance is needed.

SLITTER ACCESSORIES

Beyond the slitters themselves, slitter accessories take the industry to another level entirely. Uncoilers, recoilers, automatic coil farms and more are revolutionizing and automating the industry at a rapid pace.

When set up in a complete slit line of uncoiler, slitter, and recoiler an operation can uncoil, cut, and recoil the material needed for a specific job in a fraction of the time.

“The time and middleman costs saved by processing your own coils in house go right back to you, allowing you to run more efficiently,” said Jason Smoak, Sales Engineer, SWI.

At the peak of the slitting industry accessories are the Automatic Coil Farms. These top-of-the-line machines are becoming a must-have for high volume operations. Automatic coil farms integrate directly with your software and slitter so when a job is received the coil farm can automatically pick up the appropriate material, load it on the uncoiler, run it through the slitter and then unload and deposit the coil back into storage—all with minimal operator input. RF