Handling light-gauge coils safely and efficiently is critical to keeping things running smoothly in a construction roll-forming shop. Coils are heavy, awkward, and expensive—so having the right equipment in place really matters. Whether you’re upending, tipping, lifting, or feeding coils into a line, the right tools protect your materials, reduce downtime, and keep crews working without unnecessary headaches.

Coil handling isn’t just about lifting and positioning—it’s also about making each step more efficient. If you’re moving coils from storage to the line or shifting them into position, having the right add-ons can save a lot of time. But not every shop is the same, and the best equipment is the kind that fits your shop’s size, layout, and workflow. Below, we’ll walk through the coil movement process and discuss a few of the companies that offer equipment that can help you equip your facility.

Coil Upenders/Tippers

Let’s start with coil upenders—machines that rotate coils from horizontal to vertical (or vice versa). This is essential if the way coils arrive doesn’t match how you feed them into your equipment. Upenders make rotating coils safer, easier, and more efficient than other methods. ASC Machine Tools offers two styles of Off-Line Coil Upenders (tippers), with capacities ranging from 10,000 lbs. to 40,000 lbs. Both models are semi-portable and designed for freestanding operation. Metal Rollforming Systems (MRS) builds upenders with high-strength frames and industrial-rated motors for quick rotation. Acu-Form offers electric, hydraulic, or mechanically powered upenders, with compact 20,000-pound units that fit well in tighter spaces. They include fork pockets for easy repositioning, plus optional remote controls that allow operators to stay at a safe distance while guiding the coil.

ASC Machine and Bradbury offer both non-rotating and rotating upenders. Rotating upenders tip and rotate the coil 180 degrees, eliminating the need to approach the coil from a different side. This allows the coil to be placed eye-to-the-sky from storage, tipped, rotated, and picked up from the same side. A tipper that rotates while upending can be placed in a corner, saving valuable floor space and time.

ASC and Bradbury also makes a dual-purpose tipper also called downender. These units acts as a coil car, so you can rotate the coil and move it straight to the uncoiler in one step—reducing transfers and saving floor space.

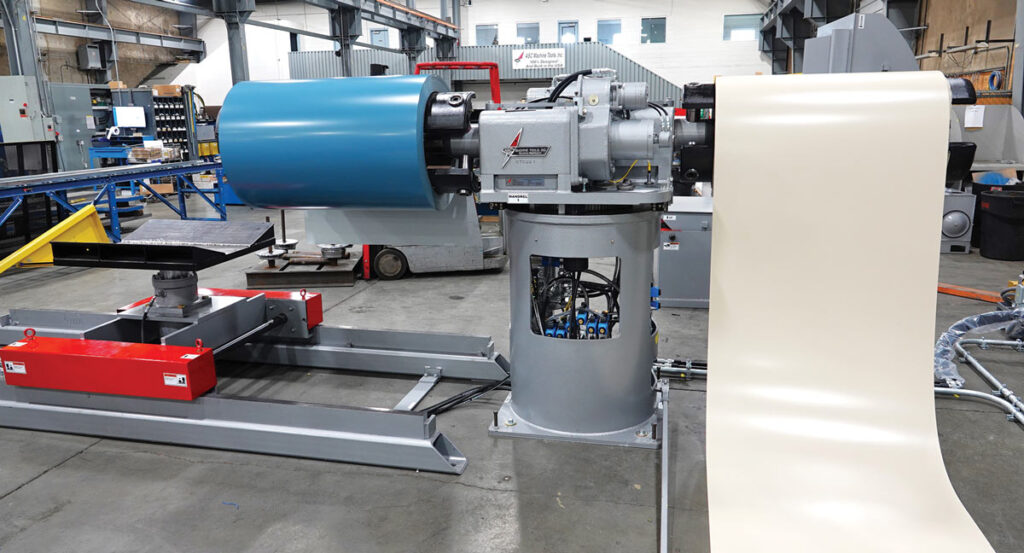

ASC Machine Tools double-arm uncoiler, 10,000 pound capacity, with coil car.

Courtesy of ASC Machine Tools.

ASC Machine Tools rotating upender. Courtesy of ASC Machine Tools.

Metal Rollforming Systems multi-station decoiler.

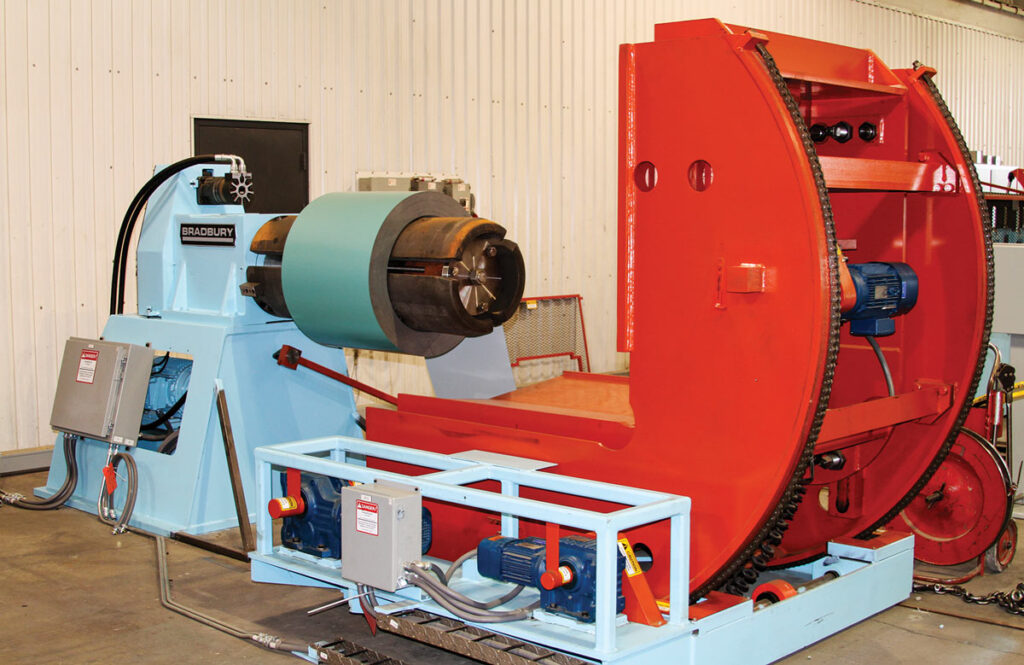

Bradbury 8-arm turnstile. Courtesy of The Bradbury Group.

Combilift C-Series moving coil. Courtesy of Combilift.

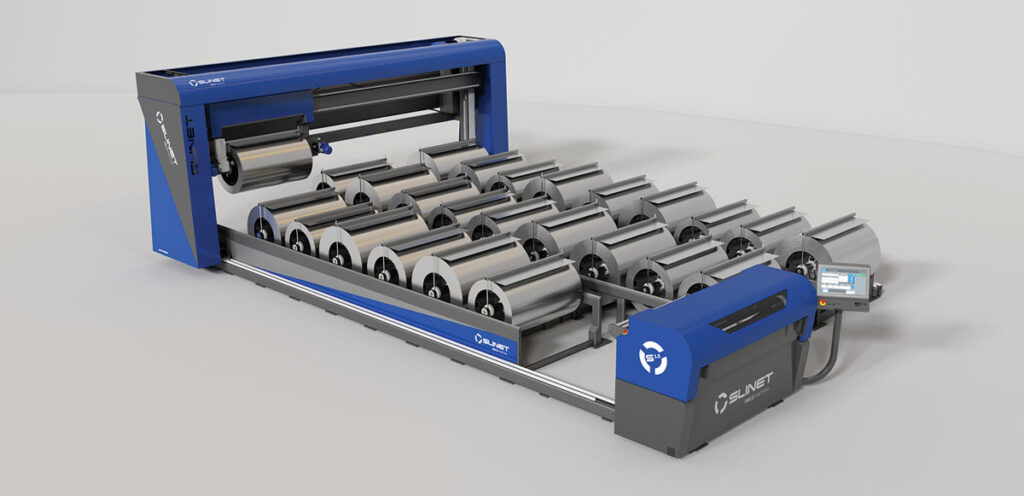

ASCO USA Slinet automated coil storage system. Courtesy of ASCO USA Inc.

Acu-Form uncoiler. Courtesy of Acu-Form Equipment.

MRS multi-station uncoiler. Courtesy of Metal Rollforming Systems.

MRS upender. Courtesy of Metal Rollforming Systems.

Uncoilers/Decoilers

Once a coil is tipped horizontally, it needs to be loaded onto an uncoiler to feed into the roll-forming line. Coil cars make it easy to load and unload coils and help position them onto the mandrel. The mandrel expands hydraulically, applying pressure inside the spool to securely hold the coil.

SWI Machinery offers modular uncoilers designed to keep things aligned and consistent. ASC Machine, Bradbury, and MRS all supply models that integrate directly with their roll-forming lines.

Bradbury single-mandrel uncoilers are available in multiple models with coil weight capacities ranging from 6,500 to 80,000 pounds, making them suitable for a wide range of applications. These uncoilers feature powered mandrel expansion, either hydraulic or mechanical, for a secure grip and efficient coil loading. Many models also include loop-arm speed control with tight-loop prevention, which automatically halts operation if the material feed becomes too slack or taut, helping maintain consistent strip integrity. With feed rates up to 300 feet per minute on select models, the company’s uncoilers are engineered for high-performance environments. Optional powered overarms assist with threading and rewinding, particularly when handling heavier or thicker-gauge materials.

ASC Machine and Bradbury both offer double mandrel uncoilers that save time by holding two mandrels simultaneously. While feeding material into the line from one side, the next coil can be pre-loaded on the opposite arm. When the first job is complete, the uncoiler rotates, presenting the next coil. Coil changeovers on an ASC double-arm uncoiler can take as little as 1.5 to 2 minutes, compared to 5–8 minutes with a single-arm setup. This difference adds up quickly—saving nearly an hour of production time over just 10 coil changes.

Another upgrade is the ASC Machine turnstile, designed to manage multiple coils at a single uncoiling station. Holding three or four coils of varying widths, it significantly reduces downtime. The turnstile rotates to align with the coil car, which picks up the next coil and loads it onto the uncoiler mandrel.

Bradbury turnstiles are storage and staging units designed to streamline coil selection and protect material within coil feeding operations. These rotary racks, equipped with up to eight arms, allow operators to preload multiple coils ahead of time, keeping them on the turnstile until ready for use.

This pre-staging process offered by a turnstile increases production throughput, minimizes forklift traffic, and enhances safety. Plus, its compact footprint optimizes floor space and boosts overall operational efficiency.

Automated Coil Storage Systems

Automated coil storage systems from ASCO USA and SWI Machinery offer substantial efficiency, safety, and space-saving benefits. These systems automate loading, unloading, and retrieval, dramatically reducing manual labor and forklift traffic. By organizing coils in horizontal racks with automated retrieval, shops maximize floor space and streamline workflow. Automated storage reduces coil damage risk and increases uptime by enabling faster coil changes. For high-volume operations, this means higher throughput, lower labor costs, and a safer, more organized workspace.

Forklift Attachments

For shops using forklifts to move coils, the right attachments are crucial. Standard forks aren’t designed for coils and can damage edges or slip under load. Coil rams, cradles, and boom attachments stabilize coils during transport. Some upenders, like Acu-Form’s, include fork pockets, allowing forklifts to safely lift and move them without extra gear.

Hoists and Overhead Cranes

In tight shops or those with heavy forklift traffic, overhead hoists and cranes offer another way to lift and move coils. With a C-hook or vertical coil lifter, a single operator can transport coils without interfering with floor operations. Companies like Industrial Equipment Designs (IED) Inc. can integrate hoists into your equipment layout for a seamless material flow.

Straddle Carriers and Mobile Handling

When coils need to move long distances—such as from outdoor storage to an indoor line—straddle carriers like Combilift’s Combi-MG offer a solution. Equipped with a rotating C-hook, it lifts coils up to 80 tons, fitting through narrow aisles and low-clearance doors. Combilift also produces multidirectional forklifts capable of carrying coils and transporting long roll-formed materials through confined spaces.

Protecting coils during handling is critical. Surface damage can turn an entire panel into scrap. Manufacturers line saddles and supports with UHMW or nylon to prevent this. ASC uses padded, V-shaped saddles for secure coil support during tipping, while Acu-Form’s centering designs keep coils stable.

Durability is also key. Shops running multiple shifts need equipment that withstands heavy use. Machines made with welded steel frames, industrial-grade motors, and centralized lubrication systems can minimize downtime. Additionally, field-serviceable designs ensure easy maintenance without extensive disassembly.

Finally, think about future growth. Even if you’re handling just a few coils a week now, modular systems allow you to scale up as your shop expands.

Conclusion

Choosing the right coil handling equipment isn’t just about lifting capacity—it’s about fitting your shop’s workflow, space, and growth plans. Thoughtful equipment choices protect your materials and keep production rolling. Making wise investments in coil handling solutions ensures safer operations, higher efficiency, and minimized downtime.

resources

Acu-Form Equipment • www.acuformequipment.com

ASC Machine Tools • www.ascmt.com

ASCO USA, Inc. • www.asco-machines.com

Combi-Lift • www.combilift.com

Industrial Equipment Designs • www.ied-inc.com

Metal Rollforming Systems • www.mrsrollform.com

SWI Machinery • www.swimachinery.com