By Karen Knapstein

Founded in 2015 as a regional supplier, Metal Wholesale LLC now sells metal roofing components to lumberyards in eight states throughout the Midwest. CEO Wilson Weiler commented on the company’s growth: “We started up in October of 2015 and it just kind of grew from there. We started out just local in the surrounding area, in the surrounding counties, and grew on that.”

To supply customers in a timely fashion, Metal Wholesale currently operates two manufacturing facilities, with a third to come online soon. The original location (and company headquarters) is located in Bloomfield, Iowa. The second location, which opened in 2020, is in Charles City, Iowa. “We’re opening a third location in Hutchinson, Kansas, in June 2022,” said Wilson.

Wholesale Metal’s business model factors into their growth; they stay focused on their customers — lumber yards. Maintaining that focus is extremely important.

Retail vs. Wholesale

While in the business planning stage, prospective roll formers need to determine who your customers will be. That is, whether you will sell retail or wholesale. “You need to know what you’re trying to accomplish and go for it,” advised Wilson. Retail vs. wholesale – each has its pros and cons.

Roll formers who sell retail can sell to anyone, including builders, roofers, and homeowners.

Since they sell directly to the end-user, they have more wiggle room when setting prices. “Someone that’s selling retail has a bigger margin to navigate through because they don’t have to make sure their dealer gets a pay margin or profit out of it,” said Wilson.

On the flip side, some things are more challenging with retail. For example, retailers may have to spend more time with each customer to make the sale, whereas wholesalers develop a relationship with a lumberyard, and they call when they need an order, which is more simple than a retail order would be.

Roll formers who decide to sell wholesale need to stick to selling wholesale. Comparing retail to wholesale, Wilson said one isn’t necessarily better than the other, “but trying to do both is a mistake. If you try to sell wholesale to a lumberyard, and sell retail to a builder, you’re competing against your customer because you’re selling to your customer’s customer. You control the profit of your customer and that’s not a good relationship. And businesses are built or torn away on relationships.”

Speaking of relationships, to assure they get the coil they need, they’ve developed relationships with several suppliers. Of recent supply issues, Wilson said, “It became more of a critical thing here in the last two years because availability has been an issue. It goes back to the relationship side of things. You need to have good relationships to get product.” He also points out you need to maintain solid relationships with your customers, so they remain loyal to you in volatile times, as well.

Scaling Up

When discussing advantages of selling wholesale, he said, “If you can get the structure right, you can scale up. There’s an element of scale on the wholesale side. You need to have a volume and variety of coil on hand to meet bigger business needs. There’s more at stake with a bigger business.”

As one would suspect, when a business provides quality products and services, word gets around. When those products and services don’t measure up, word gets around even faster. “With wholesale, you’re impacting a lot more customers,” Wilson explained. “Quality is a very big deal. Whether it’s coverage of your panel, the way your panel laps, or the trim being made to perfection on every single piece. In every detail, the effect is multiplied because you’re working through different levels. So many more people are impacted.”

Winning Equipment

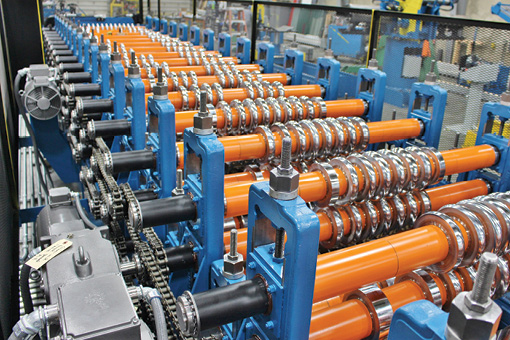

Metal Wholesale locations operates the same equipment at each of its locations because it’s efficient. The maintenance and IT personnel can become familiar with the equipment at one location and they are then capable of working on the equipment at any location. The company equips its manufacturing facilities with SWI Marksman Pro cut-to-length slitters and an SWI recoiling line. They also use The Bradbury Company’s Hayes Roll Formers with a flying post-cut shear (to speed up productivity) and VarioBend folders from Hershey’s the Metal Meister. “Jason at SWI is incredible and I appreciate working with him. So are Nelson and his team at Hershey’s,” Wilson said enthusiastically. “Good equipment is important for short lead times.”

The company continues to grow, a fact to which Wilson attributes most of the credit to his team.

Winning Team

Wilson said, “We’re focused on bringing in good people. We’re blessed with a really good team.

We run three shifts at Bloomfield and there’s always someone manufacturing, loading, whatever needs to be done.” The company is fortunate in that it doesn’t have staffing issues. “We have a lot of applications on file. It’s not because there’s not employment issues in the world – it’s a huge problem. But we’ve been able to avoid that with being very particular with who we bring on and with our company culture. We keep a positive, friendly culture; it has helped us to not have an issue with staffing.

“I’d say 90% of the success we have is because of the team we have,” he continued. “It all builds off the team. The people you surround yourself with will determine the success in your life. The things I’ve seen happen in my life – especially with Metal Wholesale venture – it’s not because of anything I or my partner did. You have to surround yourself with like-minded people.”

Challenges

While things are going well, Wilson said they’ve had their challenges; manufacturing for the wholesale market has different challenges than for the retail market. “A lumber yard isn’t just going to switch over tomorrow to a new supplier. They have a customer base and they’re not in a hurry to jump suppliers,” he explained. “You have to build a relationship and earn their respect before they will trust you. You have a time delay. It may be years to get them to trust you. That’s why most people don’t do wholesale; it takes a while to pay off.”

Profit margins will also be different. “When you’re selling to a dealer, the dealer has to make a profit as well. It increases the importance of good relationships,” he said. “You have to create value for your customer.” You have to provide a quality product that your customer can sell for a profit.

Outlook

Wilson observed the market is growing, but it’s also changing. Entry into the formed metal market is easier than it was years ago, but he’s not concerned about oversaturation. There’s still plenty of room to grow. “The point that a lot of people miss is that one person doesn’t have to lose for another person to win. It’s a big world. Multiple companies can have success at the same time. That’s what a lot of us get hung up on: ‘Someone else has to lose so I can win.’ The metal roofing market is growing in leaps and bounds. There’s more metal roofing being used all the time — on houses and bigger buildings, and it’s a growing market, which is a good thing. It’s environmentally friendly. It’s a very positive product for the world. It’s going to continue to grow. It outlasts shingles by several times and applications continue to improve, whether it’s the panel profile or the coatings.”

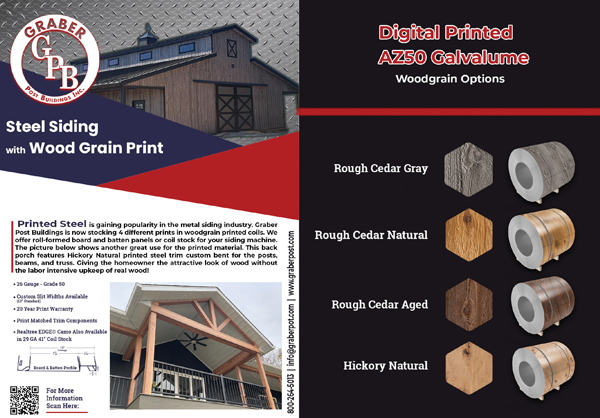

Speaking of coatings, Wilson is enthusiastic about textured coating developments. “Textured metal is huge,” he said. “It’s extremely fade resistant. So, the industry is evolving tremendously. There’s a lot of positivity. A lot of roll formers don’t realize how much better textured paint performs. It’s been tested on test fences enough that it’s proven to outperform smooth SMP and smooth PVDF.” The textured coating is also SMP, but since it reflects more of the UV rays it performs much better.

Conclusion

Metal Wholesale LLC (MetalWholesaleLLC.com) manufactures on demand, which is very different than many retail roll formers out there who are stocking up on panels and trim. Of manufacturing on demand, Wilson said, “Material, equipment, and manpower are all critical. You need the right equipment for the job, the right team for the job, and any business is a balancing act. You’ll never have it right 100% of the time, but you do the best you can and you must be willing to change. Being willing to change is a critical part of survival.” RF

Get a Free Subscription to Rollforming Magazine

Anyone who is involved in the metal-forming trade is welcome to sign up for a free print or digital subscription of Rollforming Magazine. This go-to resource for construction metal-forming professionals is published 6 times per year.