Time is money and equipment malfunctions are never fun to deal with. Doing everything you can to prevent equipment downtime and to keep your machines running at peak performance, some pros in the industry were nice enough to give us some tips to help you keep your equipment in the best shape possible.

According to Wayne Green, product manager, management software and services of AMS Controls in Maryland Heights, Missouri, AMS Controls markets itself as setting the standard for operational efficiency in the metal forming industry. AMS Controls makes machine controls and they offer control solutions for hundreds of machine types. These solutions strive to improve accuracy, quality, efficiency and maybe most importantly, they gather information about what’s really happening at each machine.

This knowledge allows their customers to truly manage their production.

What Are Some Tips To Maintain Your Roll Former?

“When it comes to producing accurate high-quality parts, predictable timing, friction and speed are extremely important,” Green said.

To maintain a high level of predictability, Green said, the following tips are highly recommended:

Cleanliness:

“The biggest tip I can give on maintaining your roll former is cleanliness. Keeping the roll-forming line clean and free of metal shavings and debris gives you the opportunity to closely inspect the machine. Remove any debris that is lodged in the roll former and vacuum the machine,” Green said.

Vacuuming is more effective than using compressed air because the compressed air is likely to push the debris into critical areas such as dies, chains and bearings that are located within the machine. The dies in the roll former should always be kept clean. Daily cleaning and inspection of the dies minimizes die wear and helps expose potential problems early.

The best way to clean the dies is by spraying a cleaner/solvent and letting the machine run empty for a number of minutes.

After this, lockout the machine and wipe the dies with a clean towel. Repeat the process until all the dies are clean. Equipment should always be emptied of any material after completion of the day’s tasks.

Lubrication:

Green goes on to point out that taking care of your roll former involves routine lubrication performed at regular intervals per Original Equipment Manufacturer (OEM) specification.

“Most roll-forming equipment have very similar servicing requirements. The shear blades should always be well oiled so that the cuts made are clean and precise,” Green says. “The right lubricating oils must be used for this purpose. Lightweight and environmentally-friendly oils are recommended for roll-forming machines. Heavy and penetrating oils make the blades sticky and consequently cause blunt cuts.”

Note: Do not use WD-40 as a lubricant. This product is made with a cleaning and degreasing solvent and it can get sticky and gum up. The WD stands for water displacement.

Coolant:

If your roll former uses coolant, make sure you have a clean and accurate coolant mixture.

“It is very critical,” Green says. “Use a refractometer to measure the recommended concentration and it should be done on a daily basis. If you have too much water in the coolant mixture it can cause the dies to stick together. This will affect the performance of the machine and the finished product. The quality of the coolant is a significant factor to consider the more aggressive the forming process and the higher the speed the material is formed.”

Hydraulics:

Roll-forming equipment often uses high-speed valving that needs to operate to the high levels of performance. To maintain this level of operating efficiency, the hydraulic oil must be free of impurities. This is maintained by the use of the OEM-recommended oil that is in line with the hydraulic filters being used.

“These should be scheduled for change on a regular basis,” Green said.

Some hydraulic systems have a filter life indicator. This usually has three ranges:

• Green: filter is good;

• Yellow: the filter is still working, but will need to be changed soon;

• Red: the filter is essentially operating in a bypass mode.

Once in the red, the filter is not filtering at all. There should be daily checks of the hydraulic oil levels.

The hydraulic oil at a minimum should be changed twice a year. It is wise to clean out the reservoir to remove as many impurities as possible. If your line has a hydraulic accumulator, it is important that the designed pressure of the nitrogen should be maintained.

For best practice, check the nitrogen gas pressure on a weekly basis. The hydraulic hoses operate under extreme pressure.

During each cycle of operation, they flex and bend. Hoses that show sign of abrasion and leaking, should be replaced immediately.

Pneumatics:

Compressed air serves many purposes in the roll-forming operation.

“Ideally, there should be no leaks. Leaks reduce the performance level of your shear or punching operation and should be fixed immediately,” Green said.

In-line oiler and water separators should be checked and maintained daily.

Environmental factors such as temperature and humidity levels greatly affect the performance of your roll former.

Having the proper equipment to minimize the environmental factors will go a long way in minimizing wear and tear on your pneumatics and ensure predictable performance of your punch or shear.

Drive Systems:

Drive mechanisms such as chains and belts should be checked regularly for proper tension and for excessive wear.

“Adjust the tension per the OEM recommendations,” Green said. “If there is excessive wear, replace the chain or belt. Gear box oil levels should also be checked regularly and changed yearly.”

Any Tricks To Making Maintenance Easier?

As with any mechanized piece of equipment, a regular cleaning schedule will increase its life and make maintenance easier, Green said.

“If this is done on a daily basis, the process will only take a few minutes each day and will save you a lot of time in the long run,” says Green. “A production management software is very helpful to accurately maintain the roll former’s performance along with recording every event that occurred on the line. This is helpful in diagnosing problems and developing a preventative maintenance plan.”

According to Green, a roll former can last up to several million feet if properly maintained. “When talking life of the dies, it depends on the type of steel used to make the dies and the finish on the dies,” he said. “The line speed, acceleration and deceleration rates of the roll former also plays a major role in the life of the line.”

Does Your Company Offer A Maintenance Service?

“Our company [AMS Controls] offers a production management software that can significantly increase production capacity through the elimination of downtime due to data entry. Information about downtime and scrap can also be used to guide operator training, capital expenditures and continuous improvement programs.”

AMS Controls also offers an optimization consulting service where they will evaluate a company’s roll-forming activities and offer guidance on how to improve productivity and yield.

What Should You Do If Your Roll Former Is Having Problems?

“I would document the issues you are having,” Green said. “Include the profile, material chemistry and speed of the line to start. Then call the manufacturer of your roll former or a company that specializes in roll forming and consult with them.”

Anything Else You’d Like To Add?

The most important advice is to understand that cleanliness of your roll-forming line and a regular maintenance schedule is essential to producing a consistent quality part at the OEM-recommended top speed.

Benefits Of Factory-Service Technicians

There are many benefits on being able to call on factory-service techs to maximize the life and uptime of your equipment

Metal RollForming Systems (MRS), in Spokane, Washington, takes a different approach to maintenance and is proud to offer their customers not only the high-quality machines, but also high-quality customer service—factory technicians that come to your job site.

“By having an MRS factory tech on site at your facility to properly tune and adjust your machine, you will be capitalizing on their years of experience in solving any current issues and preventing future issues,” says Bill Griffin, with MRS.

Here are just a few of the services that their technicians offer while on site:

Roll former:

1. Training on preventative maintenance (PM) roll-former maintenance;

2. Tooling maintenance & adjustment;

3. Grease bearings; and

4. Tension & lubricate drive chain.

Infeed Table:

1. Inspect & adjust entry guides as needed;

2. Grease bearings; and

3. Inspect & adjust belt tension.

Shear:

1. Training on PM maintenance;

2. Rotate shear blades, as needed;

3. Grease bearings;

4. Adjust brass gibs;

5. Tension & lubricate drive chain; and

6. Purge air tank & water trap.

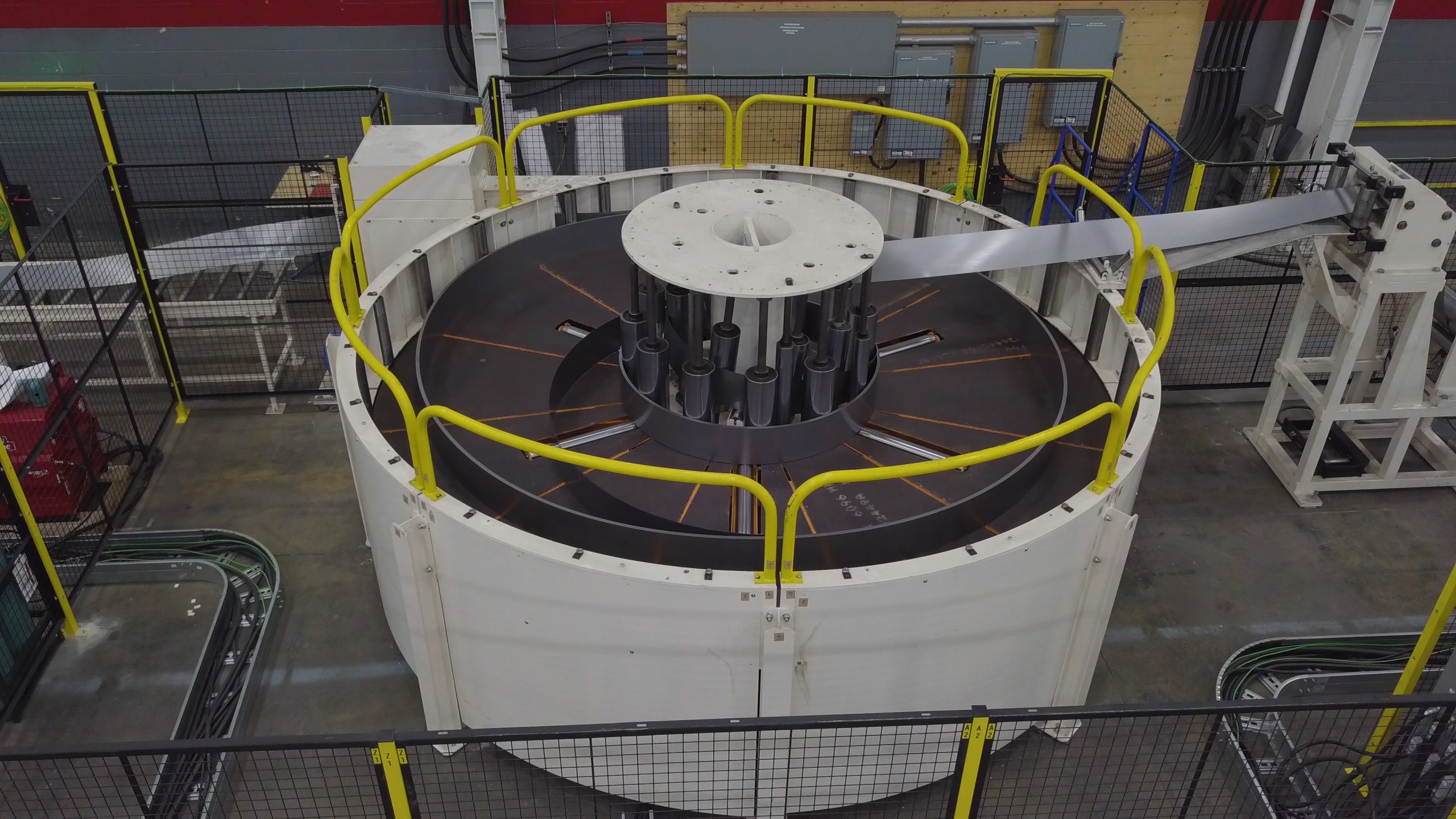

Uncoiler:

1. Training on PM maintenance;

2. Remove & replace hydraulic oil & filter (customer supplied);

3. Grease bearings; and

4. Tension & lubricate drive chain.

Trim Rollformer:

1. Training on proper PM maintenance;

2. Tooling maintenance & adjustment;

3. Grease bearings; and

4. Tension & lubricate drive chain.

Cut-to-Length Slitter:

1. Training on proper PM maintenance;

2. Rotate shear blades, as needed;

3. Grease bearings;

4. Adjust brass gibs;

5. Tension & lubricate drive chain; and

6. Purge air tank & water trap.

Ridge Press:

1. Training on PM maintenance;

2. Purge air tank & water trap; and

3. Inspect dies and guides for wear.

Coil Upender:

1. Training on PM maintenance;

2. Visual inspection of wear;

3. Grease bearings; and

4. Tension & lubricate drive chain.

“We help keep machines in a high-performance state, because we realize it’s vitally important to any business,” Griffin said.

For more information regarding preventative maintenance on your machines, please contact AMS Controls, Inc. at 314-344-3144 or Metal Rollforming Systems at 888-284-6794. RF

Maintaining Your Roll Former For

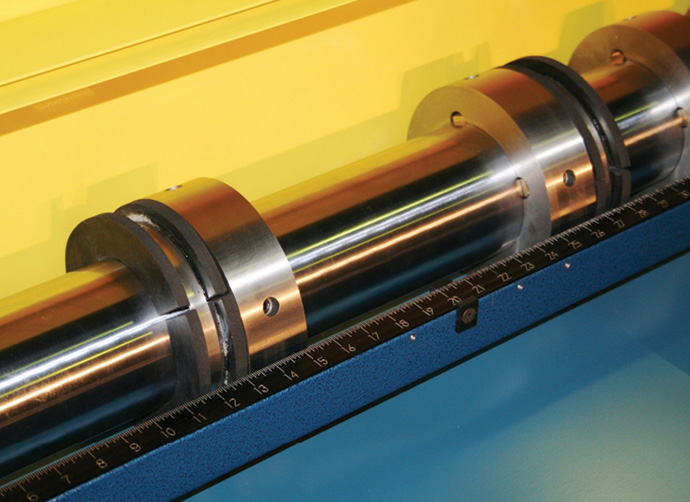

- MRS designs and manufactures industry roll-forming equipment in house.

- The Titan Series roll-forming line is a real work horse. The durability of the roll former allows for a higher production rate and ease of maintenance.

- The Titan Series roll-forming line has a heavy-duty design.

- The shear comes standard with every purchase.

- The roll-former line has an automatic friction- controlled drive system.

- Hardened steel tooling is one of this line’s great features.