Increase productivity and reduce labor with a trim roll former.

If you’re like most roll forming shops you are most likely producing panels on a roll former and trim pieces on a folder. This is an excellent way to establish your business as it provides maximum flexibility and versatility in a compact single machine. But what happens when you want to grow and expand your business only to realize that trim production is now your bottleneck? Metal Rollforming Systems has a number of valuable options that will significantly increase your production while saving you countless man hours of labor.

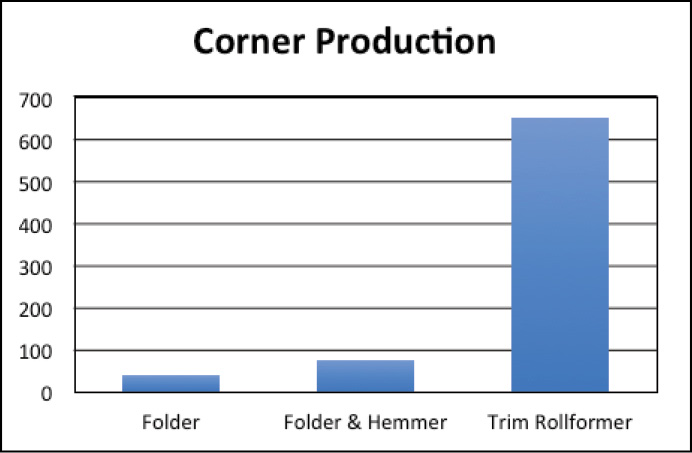

Production Times

The average 10’ corner takes 1 minute and 25 seconds to bend on a single folder. That includes the operators time to make three hits on each hem, flip it and form it into a complete part. This does not include any programing time or raw material prep.

A hemming machine increases production by allowing the operator to insert the part a minimal number of times increasing folder productivity from 30 percent to 50 percent depending on the part profile.

Trim machines can increase production exponentially. With the capacity to produce up to 650 pieces of 10’ trim in one hour it doesn’t take long to recognize a return on investment. In the metal roofing industry, it is foolish to think that you will ever get away from producing at least some of your trim on a folder, but as you can see the more trim you can roll form the less man hours are required. This increases profit on trim sales and reduces the bottle neck of trim production resulting in increased sales company wide.

Profit Margin

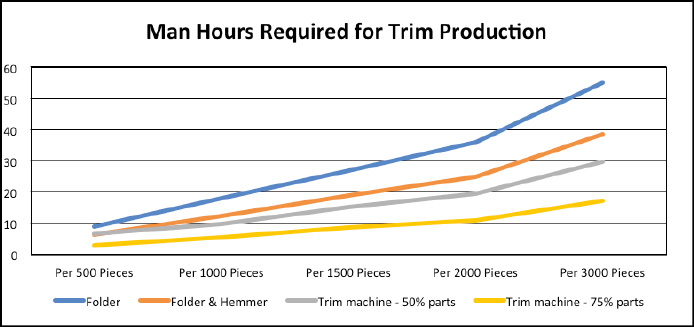

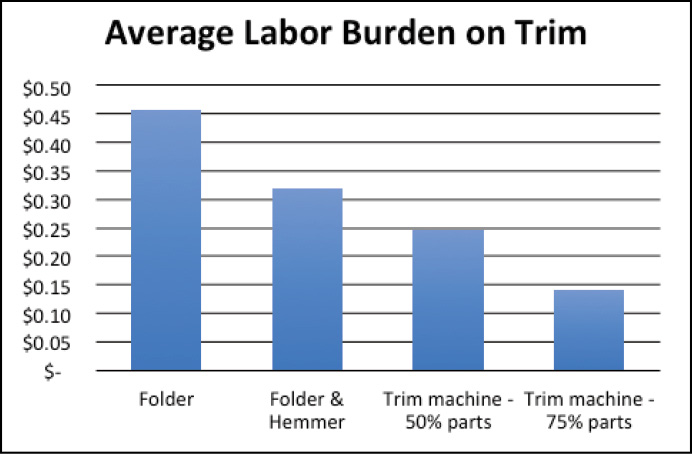

Trim components are already one of the most profitable items sold by rollforming companies. How would you like to significantly increase that margin? A single folder bending an average double hemmed part will see an average labor burden of around $0.45 on each part. Add a hemmer to your existing folder and reduce that down to just over $0.30. Roll form approximately half your parts and decrease the labor burden to just over $0.20 per part, and the savings just keep growing the more parts you roll form.

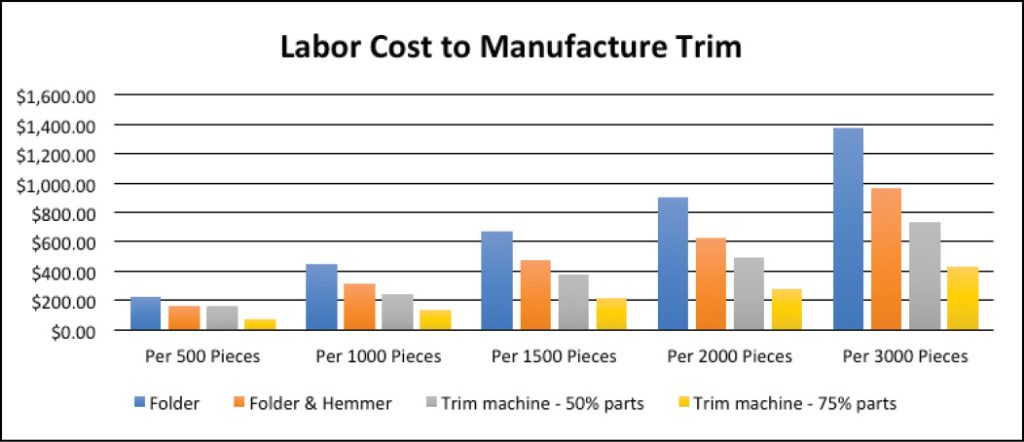

As your company grows, so do the savings associated with a trim roll former or hemmer. You can see on the graph below as the piece count increases linearly, the costs compared to trim roll formers / hemmers increases exponentially.

Evaluate Your Needs / Determine Your Budget

Now that you understand the advantages and savings associated with roll forming your trim profiles or a portion there of, you can begin to hone in on the right fit for your company. There are a number of variables and factors that combine into determining the savings associated with roll forming trim.

A. Find The Right Fit.

Often times a newer company can get overwhelmed with trim in the spring or fall during peak season. Seasonal needs may not warrant a full trim machine but may be better handled with a hemmer. Hemmers have the advantage of a low initial purchase price and the ability to provide hemmed edges for all parts going on the folder making them extremely versatile. Even if future plans call for trim roll formers, you can continue to recognize savings from your hemmer for years to come on custom profiles.

B. Profile Selection.

If volumes necessitate a trim roll former it is best to first determine the proper profiles based on the formula (time to produce x annual quantity). What you may find is that your largest volume part may not save you the most production time. Once you have ascertained your 4-8 most laborious parts review your budget and determine which machine(s) make the most financial sense.

C. Final Machine Selection.

Metal Rollforming Systems designs, manufactures, and sells a wide array of equipment that will meet the needs of any company looking to expand their trim production. From hemming machines, to single trim roll formers, all the way up to multi trim lines with the capability of producing four to six profiles. Call and discuss with a sales engineer today and start putting more money in your pocket! RF

For more information, please contact Metal Rollforming Systems at 888-284-6794.

- This is an example of the average time it takes to produce 500-3,000 pieces of trim with various equipment; folder, hemmer and trim machines.