With the demand for metal going up all the time, an important aspect of the job for the rollformer, whether in the shop or on a jobsite, is the time it takes to run the panels. Of course, rapidity does no one any good if the panel quality is not there. When it comes to panel condition, the first thing that may come to mind is the roll former and its controls, and, of course, sometimes that is the problem, but just as important is the coil handling equipment: uncoilers, tippers, and recoilers.

Decoiler Dilemmas (aka Uncoiler Complications)

Ruffled Coil

If your panel is “ruffling” or “rippling” on the edge, often the problem is oscillation, side-to-side movement of the coil, or the metal is pushed into the separation disks with enough force to damage the coil’s edge.

The first thing to check is the alignment. Align the coil with the entrance guides on the roll-forming machine.

Also check the distance between a portable roll-forming machine and the decoiler. Often experts advise leaving four to six feet between the two. Of course, space may be an issue, but give it more space, align the coil and see if that resolves it.

If the stationary uncoiler is not aligned with the shear, you do not want to adjust the shear since that would affect the alignment with the feed table and roll former. The uncoiler alignment was set during installation, and you should consult the manufacturer before trying to adjust it.

Once the decoiler is aligned, it should be fastened down. Drill holes into the concrete and use anchor bolts to hold the machine in place. Otherwise someone will bump it and mess up the alignment.

Decoiler Tension and Feed Rate

On the jobsite, roll formers tend to run slower than in the shop. Forty to fifty feet per minute can be a nice clip for panels to roll off the line when installers are moving the panels to the roof’s edge. Usually tension problems do not come into play at these slower speeds. If they do, contact the manufacturer for help.

Faster and bigger machines, are where you are more likely to experience tension problems. When working with coils, whether three, five, or ten thousand pounds of coil, the decoiler needs to be kept at the same feed rate as the machine it is feeding. If this has become an issue, perhaps it is time to upgrade your decoiler. Single speed or on/off decoilers should only be used for low speed, low volume jobs.

Decoilers are built to go with specific roll-forming machines, so there is a machine out there that is specifically built to go with the roll former that you have. These machines can sometimes be mixed and matched, but check into whether the machine can be reconfigured to work with the roll-forming machine you have. Don’t try to reconfigure your roll former to work with coil handling machines. Always allow the roll-forming machine to be the “master” machine that other machines are configured around.

Usually tension on the decoiler is handled by the sensor eye or demand arm. A bit of a coil loop between machines is a good thing. If eye or arm aren’t performing properly, coil can slip, torque and become damaged.

The problem people usually have is that the decoiler is running too slow. Speed it up. If it is electric, use the variable frequency drive to increase the speed, if it is hydraulic, turn up the pressure. For a mechanical machine, speed up the line shaft or change the pulleys.

Incorrect braking or acceleration on a decoiler can cause too much slack or too little between the shear/roll former and the decoiler, this can cause damage to coil or affect the lengths of the coil. It is properly adjusted when the material loop just touches the ground during the idle or shear time. The coil should never become taut during full line acceleration and production. Not only is it important to properly adjust infeed rolls on a pre-cut line, but also gap adjustments must be correctly adjusted to ensure engagement and drive to feed the material into the machine.

Inconsistent feed rates may require readjustment of in-feed rolls on a pre-cut line or gap adjustments on a post-cut line.

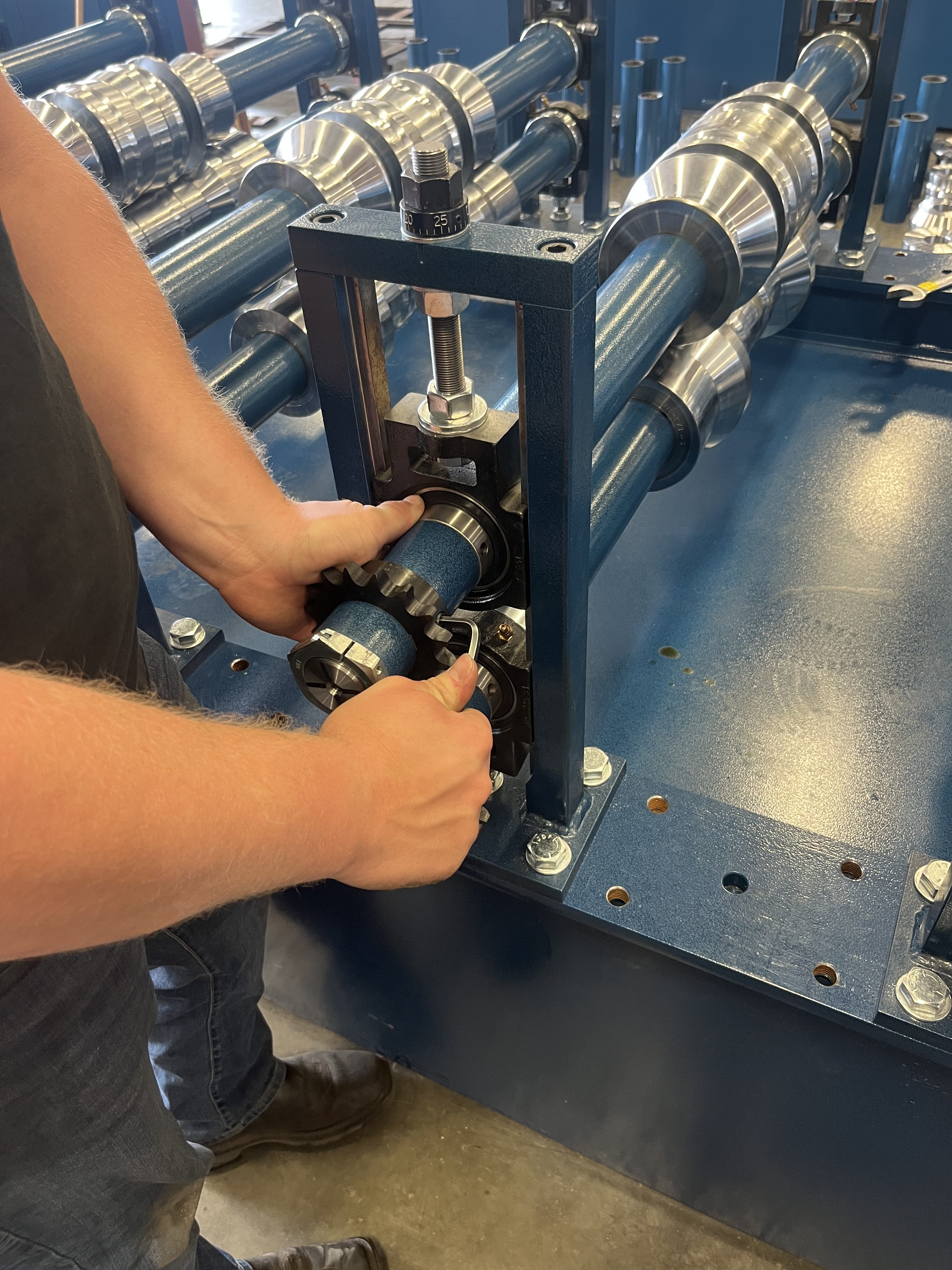

Coil Upender

Photo Courtesy of Acu-Form

Coil Car and Single Mandrel Decoiler.

Photo Courtesy of Bradbury

Tipping Tribulations (aka Upender Upsets)

Tipper problems are rare according to the experts. However, a tipper can jam if the chain is loose or breaks. Check to see if trash got under the tipper or got caught up in the chain. Finally, check to see if something is jamming the electric eye so the coil is unable to decoil.

Recoiler Troubles

Deformed Panels, Wrinkles, and Such

These problems are about trying to channel the metal into the machine without it telescoping. Wrinkling can be caused by being “trapped” by side pressure. Stop the machine and reposition the coil. Check the space between the machines and make sure you have 4-6 feet between them. That lag usually allows the coil to find its center.

Scratched Panels

When panels are getting scratched in the recoiler it is usually because there is debris of some sort on the tensioning system. Resolve this situation by stopping the machine, unplugging and cleaning it.

Remove any visible debris with a soft bristle brush or scraper; do not use anything that could scratch the rollers. Then wipe with a soft cloth, gently and methodically cleaning all surfaces. If this is not doing the trick, you can use acetone to clean away more stubborn dirt, but take care not to bring acetone in contact with rubber seals on the bearings or you will likely damage them. Then take a clean, damp, soft cloth to remove the acetone or soap residue. Finally wipe the rollers with a soft dry cloth, making sure every surface is dry before resuming machine operation.

Depending on the tensioning pads, cleaning processes can change, but if you have the common felt-style pads, follow the manufacturer’s instructions for safety protocols and lock out procedures. Then use a coarse brush to clean them with the grain, and/or compressed air to clean the surface. Do not apply any chemical solutions.

Another item to check is whether a tensioning arm’s disc or something is riding atop the coil. For example, if a neoprene roll rides on top, the coil can get burrs or pick up dirt, either of which can scratch the metal.

Tensioning adjustment is not pure science, it’s an art. No two coils are exactly the same. You may run one coil, and it’s fine, and the next reacts differently. With experience, roll formers learn how to react to the coil’s “behavior.”

Coil Slipping

Check that the coil core is tightened appropriately. Make sure slits are tightened equally.

Ask yourself is the core really slipping or are the slits just coming out different lengths? Slits tend not to be the same after they are recoiled.

Variable Lengths

Slight variances in thickness or “crowning” can occur in coil as it is processed. This is generally just a few ten thousandths of an inch, but it takes up just a tiny bit more length on each of the recoiler rotations. However, the effect is cumulative; over hundreds or thousands of feet during the recoiling process, the difference becomes noticeable. Secondary processing such as leveling helps even this out.

Another issue could be that the slitter is not set properly or the tension adjustment stand is set incorrectly. Coil has memory, so tension is required to keep it from rolling back up. If one slit looks longer than others, less tension is required. If slits are curling up, more tension is needed.

• John Dumke, Roll Former LLC

• Bill Griffin, Metal Rollforming Systems

• Michael Clark, Bradbury Group

• Wayne Troyer, Acu-Form

• Paul Zimmerman, Hixwood