By Sharon Thatcher

Metal roofers working in mountainous regions can tackle some challenging jobs using portable roll formers. Mark Orsborn, President of Colorado Custom Metal, Inc., Glenwood Springs, Colorado, is one such business owner who looks back on 21 years of manipulating metal to coat multimillion-dollar homes and commercial buildings. He has since sold his machines to enjoy semi-retirement, but offered a look back on what kept his family of seven kids fed, clothed, and home-schooled so they could go on to find successful careers of their own.

Family Business

All members of the Orsborn family, including seven children, helped throughout the years with the family business. Mark is shown with his family and the project developer.

Orsborn credits his father for aiming him in the direction of sheet metal fabrication. “My dad had a shop called Monarch Metal in Denver. I graduated from high school on Friday and went to work on Monday in his shop. I worked for my dad 10 years and learned a lot of hands-on fabrication techniques and became a crafty coppersmith as well. … We had a niche in the architectural world. Dad was a heating/ventilating professional but had an opportunity to purchase an architectural metal shop back in 1975. He was playing golf one Saturday morning and was paired up with the former owner of the metal shop. Yes, the deal was made on the golf course. That is where I learned the trade, working, shaping, and fabricating metal.”

He ventured off on his own for a while, working with other companies in the metal roofing industry before deciding to start his own business in 2000. “It was the scariest thing I ever did because I had seven kids, but it was the best thing I ever did, too,” he said, adding: “It provided a way for me to raise my family and put opportunities in front of them.”

When he started his business, he said “there were quite a few rollformers in the area.” The work was plentiful enough, however, for a guy like Orsborn who well understood the nuances of bending metal.

Orsborn had three roll formers going at one time when Colorado Custom Metal Inc. was in full swing. “I’d do these jobs in these remote areas and there’s no way you can get a [delivery] truck in there, so you need a portable roll former,” he explained. His machines of choice included a couple of New Techs and a Berridge. To cut costs, he developed partnerships with other portable owners in the area to trade profiles as needed. Shears from Swenson Shear helped him tackle the customized cutting.

At one time, Colorado Custom Metal was operating three portables. Now the machines have been sold as the owner picks and chooses his jobs and enjoys semi-retirement.

Portables Not Always Popular with Specifiers

One battle Orsborn had to fight early in his career was over misconceptions regarding the quality of panels manufactured from a portable roll former.

“Specifiers would say you need at least 22′ [of space with more turning stations] to roll a ¾” snap seam. They just didn’t think you could do it in 12′ without oil canning the hell out of it,” he said. “Oil canning in metal roofing is caused predominantly by the installers as they overtighten the panel hold-down clips or they don’t take time to shim the low spots in the substrate. However, roll formers can get out of whack…”

Orsborn wouldn’t back down. “I would challenge an architect,” he said. “When I would get a job that said, ‘panels must be manufactured in-house and shipped to the site’, I’d say, ‘okay, so you are going to crate these panels and then ship them up to me in Snowmass, Colorado?’” It was a challenge for Orsborn to trek his own team and equipment up those mountains to a job site, let alone a tractor-trailer loaded with metal. Tongue-in-cheek, he would promise to build a shack around his mobile roll former so it would comply with the specifier’s in-house stipulation.

There were ample reasons for the skepticism that portable owners faced early on, not only from specifiers but stationary roll-former manufacturers and shop-based panel manufacturers who questioned: Where was the quality control? Where were the safeguards to assure that the panel met specifications? Orsborn understood that it was incumbent upon users of portables to use them properly so as not to lose any ground in the fight. “I had to fight that battle, but we eventually won it,” he said.

With today’s acceptance of portables, and user-friendly equipment improvements, battle scars are now often self-inflicted—portable users who don’t learn to use them or how to maintain them properly lose reputations and business and generally have quality issues.

For advice, Orsborn said, “Don’t treat your roll former like any old tool, where your guys just take it out and beat on it. Treat it like a finely built automobile, one that you would maintain properly, keeping it out of the weather. Clean it, oil it, and adjust it properly before and after each project. Have one person or a team dedicated to it. Train them really well, so you can run a good quality product.”

He has seen too many portable owners ignore that idea. “I’d go some places and ask them, ‘where’s your roll former,’ and they’d say, ‘well, it’s out back by the dump truck.’ It’s not that type of a tool; it is a precision fabrication tool.” Though not difficult to maintain, proper adjustments are critical.

LESSONS LEARNED ALONG THE WAY

It pays to listen to experience, and Orsborn said the lessons he learned along the way served him well. Some additional main points he shared:

Finding and Keeping Good Help

Orsborn said he never had any major problems finding and keeping good help. His advice: “Hire character. You can’t train that into people; you can teach them a skill, but you can’t train character.”

He spent a lot of time in the interview process with applicants, taking them to lunch and observing their ways. “I got really lucky,” he said. “My best guy just walked into my office one day and said: ‘I don’t know anything about sheet metal, but I’ve got a wife and kid out in the car and I need a job.’ I could tell in my gut; so, I trained him to be quality-minded and he turned out to be one of my best guys and we were together for years.”

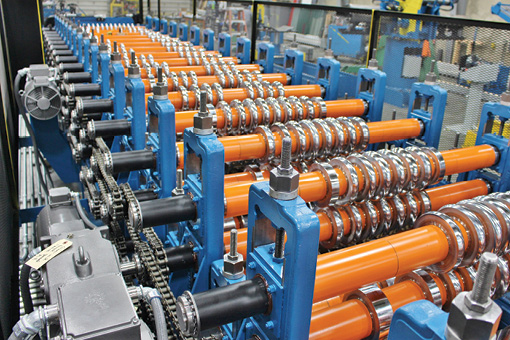

Orsborn was able to coax his machines into accomplishing some interesting jobs, including the cold rolled steel roof shown at right.

Price the Job Fairly

“Be honest with your customers and don’t try to get rich on every job,” Orsborn said. “Standardize your procedure and make [price] a certain percentage. You get rich by doing quality work consistently, not by capitalizing on every job.” Pay attention to the smallest details.

He was tempted to lower prices early in his business to be competitive, then soon abandoned that idea as he gained experience. “At first I didn’t have a good handle on how much it cost to run my business. After I figured that out, I just ran with my own program and I didn’t really concern myself with what other companies were doing. People would ask me how much per square, and I’d say, well every job is different—Colorado Custom, it’s called that for a reason. I could have doubled the price on some jobs and still gotten the job, but I don’t think we ever got into a job where we just went totally upside down and it cost me money.” The one exception was an out-of-state customer who promptly sent a down payment on a commercial job, the job was completed, the final bill came due, and “I never heard from him again.”

Open Your Mind to Other Possibilities

Some things you can’t learn in a book. Orsborn said he has learned a lot about the thermal movement of roofing panels that wasn’t outlined in book standards. “Panels don’t just grow in one direction,” he said. “The ‘book’ will say that if you have a [panel] that is over 30′ long, then only fasten it at one end so it can grow the other way. But metal doesn’t do that as it heats. I’ve got a 68′-long panel installed on a casino in Blackhawk, Colorado, and I had to pin the top and the bottom. The panels have been sitting in place for over 10 years and they’re perfectly fine.” Added into the equation in this instance is the fact that the roof is steel, which does have a different coefficient of expansion ratio than other metals like copper or zinc.

Roll the Correct Coil

Not every coil adapts well to roll forming, Orsborn cautioned. An example is galvanized metal that leaves metal deposits on the rollers. If you do run galvanized, make sure the rollers are well coated to avoid damage to panels from metal shards.

Another steel to avoid is 80,000 KSI tensile strength, which is very hard and may break as it’s being formed. For panel forming, 50,000 tensile strength is more common.

Find Allies in Architects

Having an architect who respects your expertise is invaluable. You may not always be able to pick and choose, but when found, they can be true allies. Best are those architects that allow the contractor to decide what is best practice for manufacturing and laying panel rather than to dictate every decision. “When you have an architect standing like the Corps of Engineers saying, ‘you will do it this way,’ it’s like, I just learned my ways, now I have to learn yours?” Orsborn said.

Watch Out for Waste

“I see so much waste,” he added. “As the owner, you have to know what’s going on in your business. Keep a close eye on things, and know what you’re doing.” Spending a few extra hours to work out every detail on the front end of a project is far more cost-effective than having to go back and repair things that were not engineered properly to start with.

“I always had a very thorough pre-job meeting with my foreman.

“Even though we were a custom shop, I would always pre-punch holes to the proper fastener spacing in our flashings and pre-notch end laps to the required lengths before ever letting the metal leave the shop.”

Moving into Semi-Retirement

Although his roll formers have been sold and his crews have departed, Orsborn takes an occasional job to be with family. All seven of his kids—three boys, four girl—have helped with the family business for years and still take working vacations together on select projects. At the time of our interview, he was preparing to roof a large home in Steamboat Springs, Colorado. “My whole family will come up. It takes us about three weeks to do a house,” he said. “The owners, developers and other trades on these jobs are quite impressed with the way my team works so well together. It’s not often you will see four girls show up on a construction site and start roll forming architectural metal roof panels. That is what we do.”

The kids were very diligently home-schooled by Orsborn’s wife, a physical therapist by profession. Orsborn said, “She had a no-nonsense approach to raising the kids—holding their feet to the fire and insisting that each child would follow through with what they started. One son graduated from Denver University at an early age and is working in corporate finance, one son worked tirelessly on his skills (which opened doors for him to find a job playing professional hockey in Sweden), one son is a professional in the golfing industry, two of my daughters are former Miss Colorado Outstanding Teen winners—one now a life coach in southern California and the other attending college in Arizona. One daughter is a talented music producer and performer who also has started a horse ranch in southern California, and one daughter is a songwriter making her way in Nashville. They all started helping in the family business by earning a nickel for every metal clip they fabricated.”

The women of the family are up on the roof doing the same work as the guys and have earned the respect of some initially skeptical customers. “You get guys that just want to beat everything to death and cowboy everything, and girls want to finesse and think of better ways to achieve it,” he said. “If there’s grunt work involved, the guys will do it, but when it comes to the finesse, hey, girls are great.” RF

READ ABOUT ORSBORN’S FAVORITE JOB: WINGS OVER THE ROCKIES AIR & SPACE MUSEUM