By Sharon Thatcher

Best Buy Metals of Cleveland, Tennessee, was named to the Inc. 5000 list in 2021 identifying it as one of the fastest-growing private companies in the U.S.

The Inc. 5000 website says companies that make the list have displayed “brains, bravery, and optimism” to propel them to above-average growth. Best Buy Metals experienced an 87% 3-year growth rate. The company’s Chief Operating Officer Adam M. Clark drills down further to explain how the company did it.

The History

The company was founded in 2002 by Isaac Libbey. “He was a general contractor for a number of years, building homes and doing some electrical work,” said Clark, speaking on Libbey’s behalf. Metal roofing was being used in the southeast, but Libbey discovered that getting metal roofing products was a bit of a challenge, compromising the industry’s growth. Seeing an opportunity, he found his own source—a regional rollformer about 100 miles away—and started selling metal roofing kits.

Libbey continued to follow opportunities as they came his way, that included hiring Clark in 2009. A native of Vermont, Clark had graduated from Lee University near Cleveland and stuck around because he liked the area where he also had a network of friends.

Clark had been hired to sell the metal roofing system Libbey had developed and was installing. Best Buy Metals had only a hand full of workers then, so Clark found himself doing everything from selling metal to driving a forklift; whatever was needed for the day.

“I was just a silly kid at that time,” he said. “There was really no expectation the company becoming what it is today. It’s really fun to look back and say I’m able to help our machine operators because I had to do it; I’m able to help our sales team because I had to do it, but there really wasn’t this expectation when I started.”

The manufacturing side of the business followed soon after Clark’s arrival. “We purchased a metal brake first to start manufacturing our own trim and then early in 2010 we bought our first roll former,” he noted; it was a single-deck Titan from Metal Rollforming Systems. It became a double-deck 18-months later.

What happened in 2011 was pivotal: “we had some really significant tornadoes that came through southeastern Tennessee,” Clark remembers. Nearly overnight, demand for their metal roofing system doubled. “And by April 2012 we had planted our second facility in Chattanooga, Tennessee about 35 miles south of our headquarters … because we felt that we needed to serve the local community a little bit better than we could being 30 or 35 minutes away.”

Other locations soon followed. “After we realized that having multiple sites really made sense, we opened up in Asheville, North Carolina in 2013.”

At first, Asheville was just a distribution site. Manufacturing was done in Cleveland and trucks would make daily trips to Asheville. “Because we were figuring it out, we didn’t know what the demand of the market was going to be over there,” Clark explained. But “after three months running trucks there every day, we could see that the demand was absolutely there, so we invested in some equipment, and we turned our Asheville facility into a full manufacturing site.”

Also in 2013, they ended their roofing installation services. “We were losing too many [contractor] customers because they perceived us as competition, not as a resource,” he said.

In 2017, a facility in Greenville, South Carolina was added; and in 2019, Morrisville, North Carolina just north of Charlotte. Each time they started by using the new locations as distribution sites. “When we were comfortable with the local market, manufacturing was also shifted to those sites,” Clark said.

Today, the company has six divisions: one for each of the five locations, plus a national sales division for distribution of materials across the U.S. Property for yet another location has recently been purchased.

Clark’s own career path mimicked the trajectory of the company. “As opportunities came up, I took them—an opportunity to lead a team, then an opportunity to lead a facility. I really felt called to do those things because I was invested in the company, I was invested in the industry,” he said.

Today, owner and Chief Executive Officer Isaac Libbey uses his talents to concentrate on facility upgrades, while Clark manages the ever-changing, day-to-day operations and financials of the company. “The operations side of the business … is what has always really intrigued me,” he said. “I like data. I like being able to understand operational efficiencies in setting goals and helping to shape our culture, but in 2009 I had no idea that would all fall under my umbrella.

“There wasn’t this grand plan. I didn’t even have a roll-forming background; it’s just funny how it developed,” he went on. “As I’ve gotten to know more people in the industry, it seems to be a common thread for entrepreneurs: maybe they had some experience, but a lot of them happened to get pulled into the industry. I’m really passionate about it. I love this industry. I can’t imagine doing anything else.”

Three-part equation for success

Clark speaks of a three-part equation when he delves into the company’s success. “The real value we believe we bring to the equation is: #1: we have a fair price; #2: we have very, very quick turnaround time …. making sure we have same-day service for people placing orders first thing in the morning; and #3: we focus on education.”

Those are concepts other companies claim to use yet experience less success. Clark offers additional clues as to why Best Buy Metals landed on the Inc. 5000.

“I think our reputation for taking care of people certainly was the catalyst for some of our growth,” he offered. “Planting in new regions sort of happened organically when we felt we could no longer take care of the customer base that was hearing about us.”

Taking care of the customer base meant assuring that the quality Best Buy Metals had worked hard to achieve was carried through as the company grew. “Nothing kills an industry faster than a product that is perceived as poor by the end-user,” Clark said.

Moving closer to an expanding customer base was critical, so too was making sure contractors understood how to install metal roofing properly.

“For us to introduce a quality product, we control the product, and we control the quality of the materials, but the quality of the installation is equally as important to us,” he said, “so we really invest a lot of time with our contractors; sitting down, coaching them and helping them to understand proper application.”

That has been accomplished with monthly Best Buy Metals certification courses. Participants are treated to breakfast and some meaty advice.

Education doesn’t end there. They also help contractors to stay in business by offering business coaching classes. “That’s something really enjoyable for us. We want contractors who are building sustainable businesses, businesses that don’t grow up when there’s a storm (when it gets busy) and deteriorates or breaks down when business is harder. We spend time with our contractors helping them to build a sustainable business model, helping them with the pricing and proposal approaches. That’s been a really good tool for us to gain confidence with our contractor base.”

Then there’s education targeted to the end user, homeowners debating over the benefits of metal roofing. They have an online Metal Roofing University, a series of podcasts, and onsite workstations and estimating stations to help the customer understand a potential purchase decision.

Best Buy Metals only uses U.S.-made steel, domestic coatings, and top-quality screws, closures, and sealants. Conveying why that is important to homeowners is critical. “We believe that by creating a watertight system, a metal roof should last you a lifetime. If you have [a company] who’s challenging that, you really have to ask them why they are challenging that; why are they offering a cheaper product; why are they offering a system that won’t last [a lifetime],” Clark said.

“Once you have those conversations with your customers and they understand the value of buying a higher quality product, it’s a no-brainer for them,” he said. “The mentality of ‘we’ll just get the cheapest product because it’s available’ I think we’re past that. I did see some of that happening in 2009, 2010; a lot of people were thinking short-term, but I think right now people are thinking: ‘it’s inconvenient for me to have to pause and re-roof my home, and it’s going to be more expensive in 10 years [with] inflation of materials and inflation of labor.’”

Changing Perceptions

When Best Buy Metals first opened, metal roofing on residential was not seen as normal. Having a local presence and local contractors with successful businesses contributed to changing perceptions.

“We have found it takes two years of planting and cultivating [the idea] that metal roofing is normal before homeowners see it as an option for residential application,” Clark noted. “In our third year, without fail—in Asheville, then Greenville, and now in our Morrisville, North Carolina office (currently in its third year), if we plant the seeds correctly, and we create this sense of normalcy for metal roofing in the residential application, it really starts to take off. People start to see it available in many colors, in many profiles, and once you create that sense that it’s a great alternative to traditional asphalt shingles, once people start talking about it in the community, it’s not really a hard product to sell.

“The first couple years you have to do things right, though,” Clark continued. “You really have to be sure you’re educating customers on the value proposition, on the longevity of the system. If that’s done correctly, by year three it’s always been kind of an explosion of customers who think: I’ve seen that, I’m familiar with that, I want that.”

Today, 85% of Best Buy Metals’ panel systems go into residential applications.

Competitors

Clark said Best Buy Metals has two primary business models they compete against: the big box stores, and small shops focused on the status quo. Best Buy Metals studied the inherent weaknesses of their competitors to develop their own business model.

Regarding big box stores, Clark said, “they may have good resources, they may have access to a lot of materials, but they really don’t have the technical expertise. And they don’t have the time to dedicate to customers who are willing to spend on metal roofing.”

Regarding many small shops: “they’re not necessarily looking to grow, they’re really just looking to maintain, and that becomes ‘how do I cut expenses, how do I buy cheaper materials, how do I race to the bottom just so I can keep the lights on.’ For us, what it comes down to, is realizing that we have to be smarter in terms of creating a financial model or a pricing model that allows us to continue to grow. We know that a race to the bottom, a race to the cheapest product, is not going to give us the financial freedom to make some of the investments and some of the expansion that we have.”

The future

COO Clark said he and owner Isaac Libbey have had many conversations over the years about what they wanted Best Buy Metals to grow into. The fact that it would grow into a company with 160 employees and multiple locations was not anticipated.

“I think when we opened up the Chattanooga office, and we found it was a great way to get into a new community, to affect more people, that kind of opened our eyes a little bit to understand what the potential looked like,” he said.

Their plan is to concentrate their business in the southeast, at least for now. “We still do have growth campaigns going on and we anticipate that we will continue seeing similar growth for the foreseeable future,” Clark said. “I don’t foresee anything that’s going to be slowing us down unless there’s a major economic change. We’re really motivated to keep creating vertical positions for high-performing team members and we have not gotten to a place where it’s beyond our capacity yet. I think if we got to the place where we didn’t think we could do it well, we might slow down, but we haven’t reached that point yet.” RF

Machines of Choice

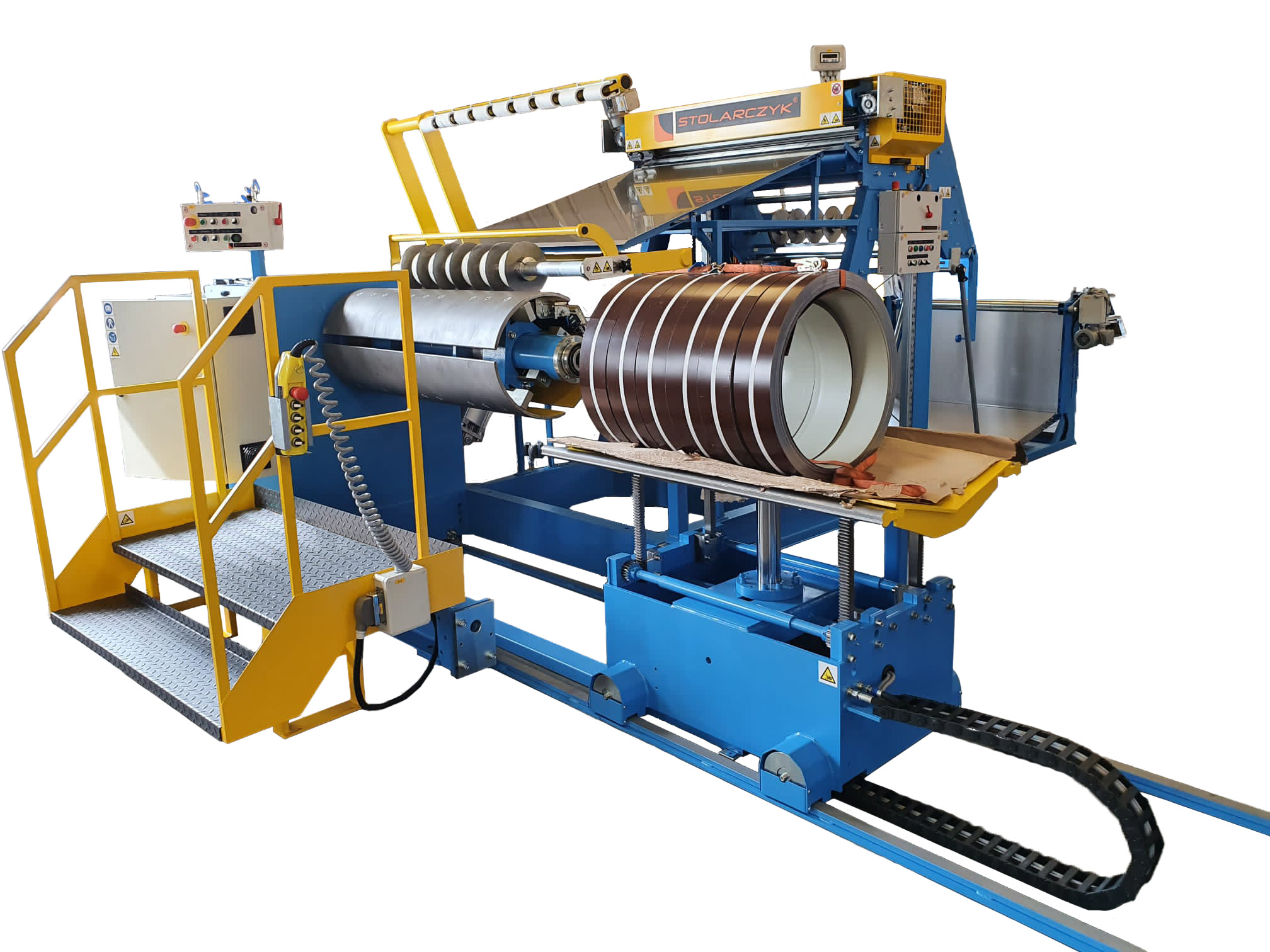

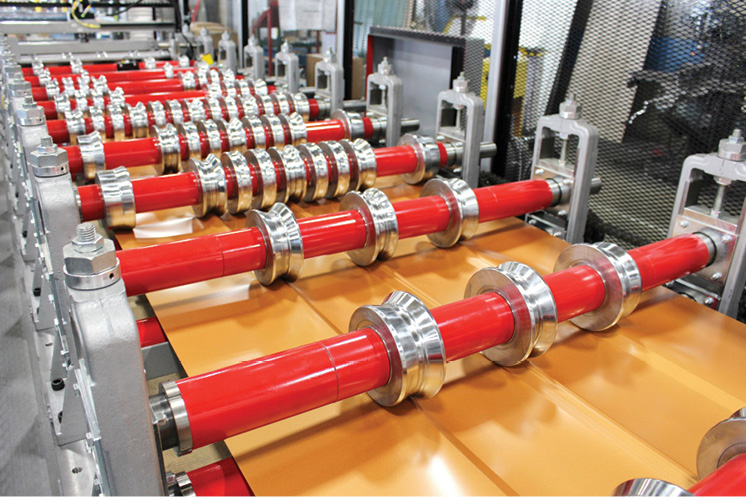

What machines do an Inc. 5000 company rely on? Best Buy Metals uses Titan double-decker roll formers from Metal Rollforming Systems for its primary plant-based machines, one deck running ag-panel, the other an R-panel.

The company also relies on two 20-foot Variobends from Hershey’s Metalmeister (one double-bender and one single); and two Marxman Plus slitters from SWI Machinery.

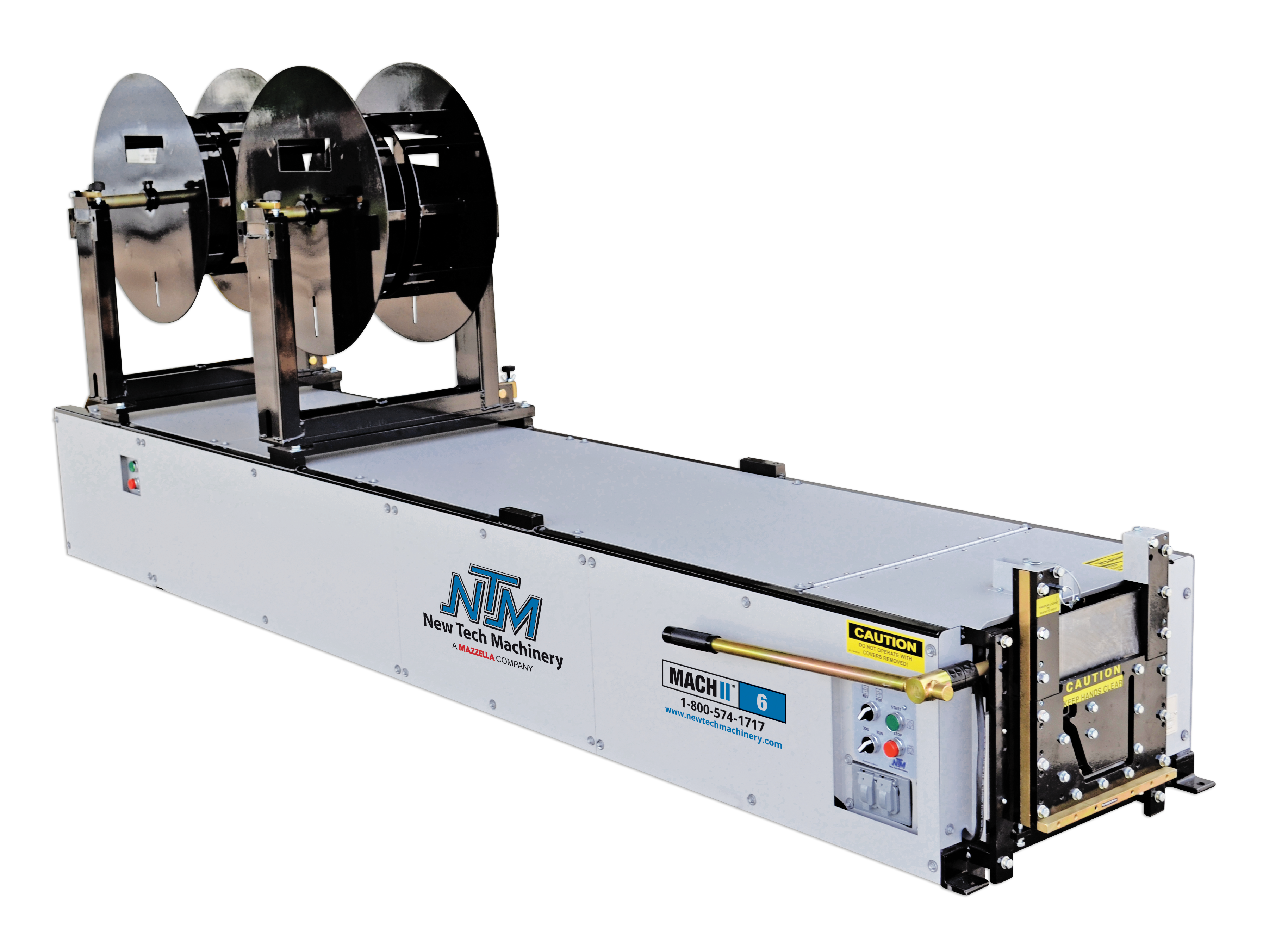

Best Buy also has 11 New Tech portables for on site roll forming of standing seam. When a portable is used, Best Buy sends its own crew to the job site. “We do all the manufacturing,” Clark said. “We don’t want a contractor to get into the position where they’re scrapping 1,000 feet of metal just because they’ve run into an issue with the machine. We have the responsibility to maintain our profile tolerances and to maintain our equipment in a certain way, so if there is a material loss, that’s on us.”

The portables have proved popular with homeowners who can see their roof being manufactured. Clark noted: “That’s something enjoyable for the customer to experience.”

Work Force Strengths

Best Buy Metals showed major growth despite Covid, and that included growth in its workforce. How did the company find and maintain workers? COO Adam Clark said the company is unique in its approach to hiring.

“Our company culture is designed around making people find joy in the work that they’re doing,” he said.

“I think that’s helped us retain a lot of people,” he added. “Some people have found joy here in the work that we do and in the culture that we set up; caring for people well has helped us retain our best team members.” RF