Construction roll forming is an interesting industry in part because of the people inside it. They are often willing to share experiences to help pave the path for others; that makes writing about the industry especially enjoyable. Here is a look back at the year 2021 highlighting some of the especially colorful quotes taken from articles published in Rollforming Magazine. It includes observations you may find useful, inspirational, or just plain entertaining.

From the man who created the first portable roll former in the U.S. dedicated to the double-lock standing seam roofing industry: “I didn’t research what roll forming was all about, I just thought, I can figure this out myself. What I came up with was a different idea of pulling the metal through, without looking at existing machines; I wasn’t focusing on how it was done normally.” – Ewald Stellrech

On starting a roll-forming shop: “Sometimes you might have to work all night just to keep up, but you have to. You’re signing your life away to get started, but eventually you hope to be able to pass some of the work on to others.” – Nathan Yoder, Your Quality Metal, Little Suamico, Wisconsin

“You just don’t know what you will need when you first start. It’s better to start in slow, where you can manage it and then upgrade as time goes on, as to jump in and start big and not be able to make it.” – Nathan Yoder, Your Quality Metal, Little Suamico, Wisconsin

The following from Victor Lottice, AA Seamless, Athens, Wisconsin:

On bending metal: “Metal has what is called memory. You have this flat piece of metal, and it says, ‘by golly, I’m going to be flat for the rest of my life.’ It has to be coaxed into taking shape.”

A lot of ‘gutter guys’ are just out there running a machine and whatever comes out goes up on the project. If the gutter is not roll formed properly it can lead to premature failure and unhappy customers! So, the first step in ‘hanging’ a great gutter is ‘forming’ a great gutter.”

On handling customer problems: “My motto to the guys is, don’t ever tell me what you can’t do, tell me what you can do. There’s always a solution. Tell me, ‘I don’t think we can do this, but I think we can do this.’ If a customer has a problem, they’re calling on us to solve it. If we can’t solve it, they’re not our customer.”

About sourcing factory workers who want to work outside and travel: “Once in a while they’ll complain about rain or cold in winter, but then we remind them of the [factory].”

On the superiority of standing seam with hidden fasteners: “When you put 2,000 screws in that roof and that rubber washer gives out, that’s 2,000 potential leaks. Even half a percent is 10 leaks … Once you cover that screw, it all makes sense.” – Albert Shrock, Cherry Fork Metals, Oak Hill, Ohio

Good Employee Relations: “My philosophy is that not everyone is going to be gung-ho about Best Buy Metals their entire life, but our responsibility as a company is to give people the skills to pursue their passions, and if that means something outside Best Buy Metals, we hope their time with us equips them to go and find something that brings them true joy.” – Adam Clark, Best Buy Metals, Cleveland, Tennessee

Reacting to Covid: “Instead of looking for problems with the pandemic upon us, we found opportunity to react for the near term, manage differently and maybe even more effectively. We used the downtime to shift thinking, re-direct resources and prepare for the pent-up, near-term demand on the other side. … With those lessons learned and 2020 behind us, we now look forward to the year ahead with a perspective and attitude of gratitude. You know, gratitude is a lot like bacon; it can make almost anything taste better—even Brussel sprouts!” – Rob Haddock, S-5!

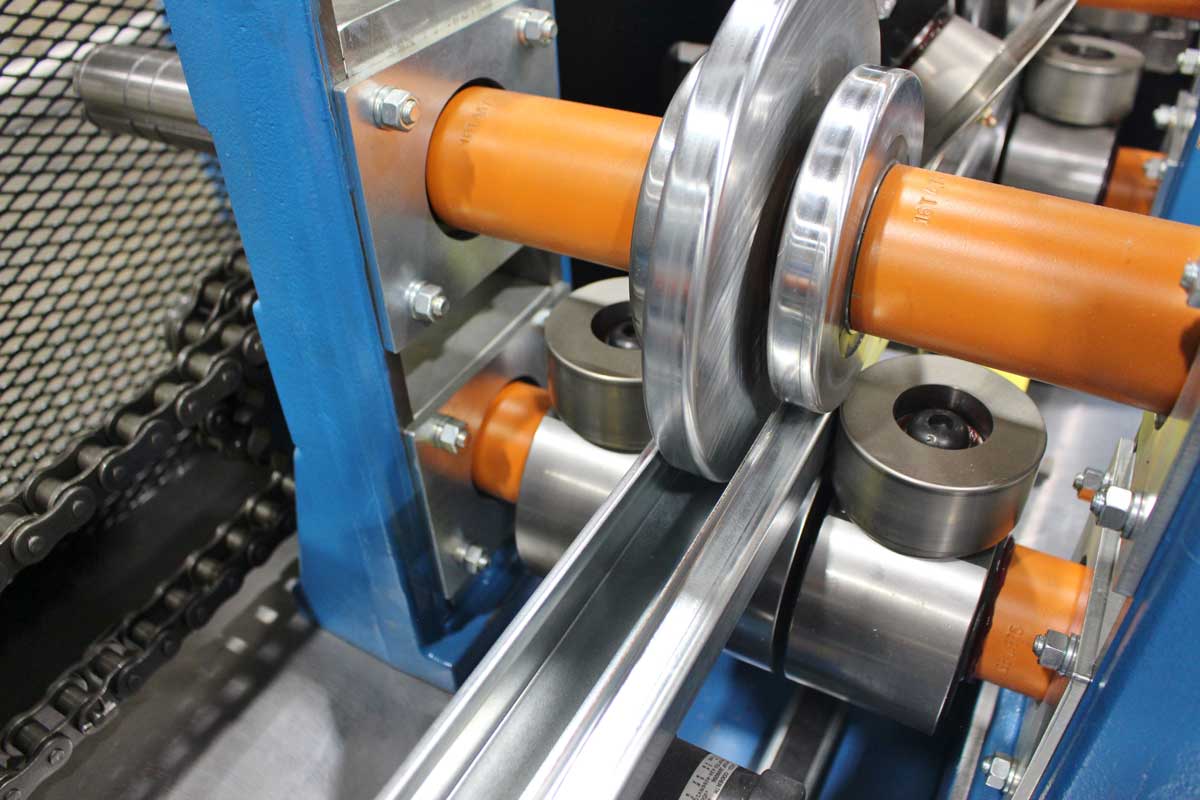

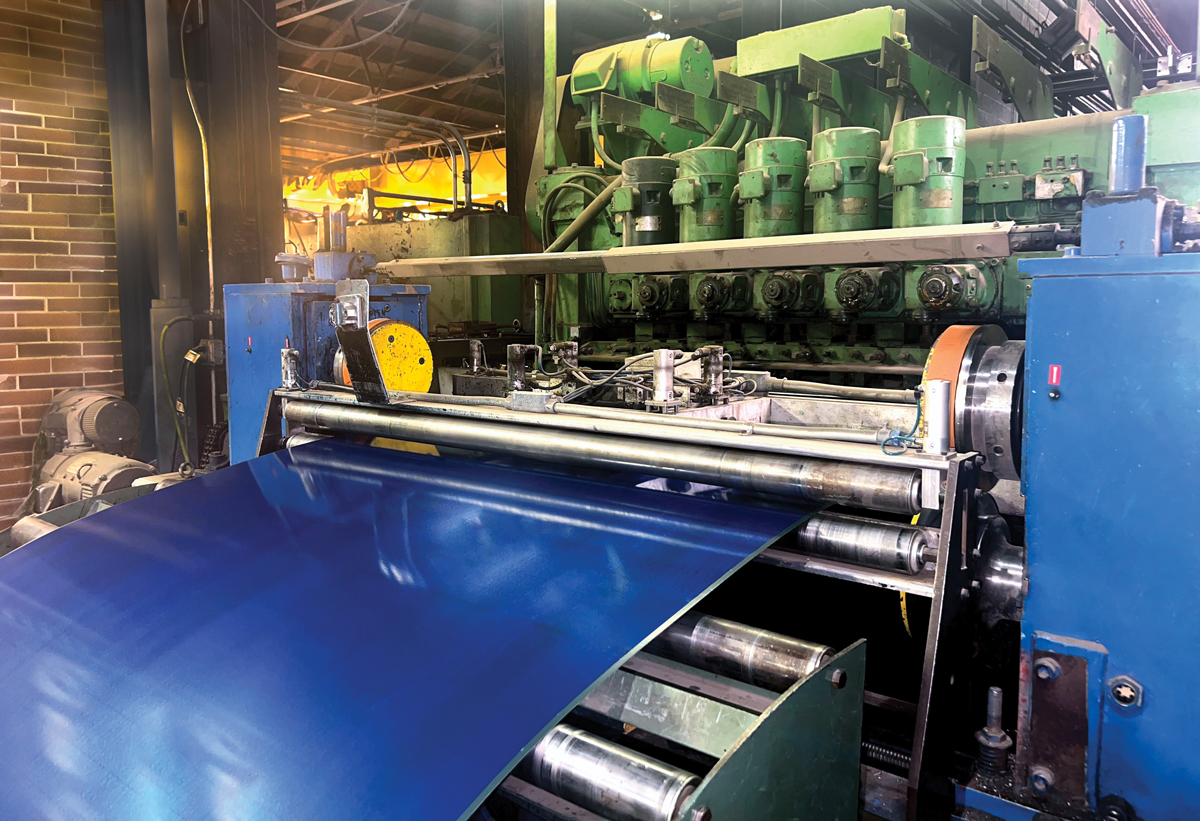

On buying equipment: “Smart buyers ask smart questions. Roll-forming equipment is not one size fits all; it is highly specialized equipment that varies widely in quality, performance, and features.” – Chris Cox, ASC Machine Tools, Inc.

The importance of trade shows: “When an owner or manager is in the office, the majority of his or her time is spent dealing with immediate issues and ‘putting out fires.’ Trade shows provide an opportunity to step away from those daily fires and think about big picture goals and strategic plans for the business.” – Chris Cox, ASC Machine Tools, Inc.

High price and low availability of steel: “We’re all in the same beat-up boat, and we’re all losing sleep at night.” – Bob Kula, Mill Steel

“It’s been a tale of two universes…we’ve gone from one extreme to the opposite, from the beginning of [2020] to where we are today.” – Steve Swaney, Flack Global Metals

On buying trailers for portable roll formers: “The good ones will cost you, but they will last you.” – Larry Schlabach, Masterpiece Metal Roofing, LaGrange, Indiana

The importance of eliminating shipping damage with stretch wrap systems: “Vibration from wind or chatter from the road creates a harmonic rubbing together of the panels. It is like an ultrasonic effect that creates an abrasive situation—like sonic sandpaper.” – Robert Bowlin, Ameripak

On the issue of “sheet separation” or “sheet delay time”: “As an owner you want to see that number minimized to maximize productivity. Every second of delay is a second the machine is not producing panels.” – Bill Griffin, Metal Rollforming Systems

The following from Mark Orsborn, Colorado Custom Metal Inc, Glenwood Springs, CO:

On starting a metal roofing and portable roll-forming business:

“It was the scariest thing I ever did because I had seven kids, but it was the best thing I ever did, too. It provided a way for me to raise my family and put opportunities in front of them.”

On equipment maintenance: “Don’t treat your roll former like any old tool, where your guys just take it out and beat on it. Treat it like a finely built automobile, one that you would maintain properly, keeping it out of the weather. Clean it, oil it, and adjust it properly before and after each project. Have one person or a team dedicated to it. Train them really well so you can run a good quality product…I’d go some places and ask them, ‘where’s your roll former,’ and they’d say, ‘well, it’s out back by the dump truck.’ It’s not that type of a tool; it is a precision fabrication tool.”

On hiring: “Hire character. You can’t train that into people; you can teach them a skill, but you can’t train character. … My best guy just walked into my office one day and said: ‘I don’t know anything about sheet metal, but I’ve got a wife and kid out in the car, and I need a job.’ I could tell in my gut; so, I trained him to be quality-minded and he turned out to be one of my best guys and we were together for years.”

Pricing the job fairly “Be honest with your customers and don’t try to get rich on every job. … You get rich by doing quality work consistently, not by capitalizing on every job.”

On working with architects: “When you have an architect standing like the Corps of Engineers saying, ‘you will do it this way,’ it’s like, I just learned my ways, now I have to learn yours?”

Regarding women roofers: “You get guys that just want to beat everything to death and cowboy everything, and girls want to finesse and think of better ways to achieve it. If there’s grunt work involved, the guys will do it, but when it comes to the finesse, hey, girls are great.”

On life: “Today is a gift. Let’s make the best of it.” – Quote frequently used by the late Chris Ray (1960-2021), Levi’s Building Components