Estimating software is great for productivity, but you may not be getting your money’s worth if you neglect to use all the tools included. Ray Smith, Managing Director, AppliCad Software, sees this all too often. “One of the problems that I have noticed is how easy it is for an estimator to miss many small details in their quotation and in some cases, not even notice that they have been missed,” he said. These missed items can end up minimizing your profit margin and possibly even contribute to a loss.

One group of items more frequently overlooked include fall protection expenses, specialized trims, site preparation or cleanup, dumpster expense, power poles and connections. As well, specific accessories that, if not ordered and delivered at the start of a job can hold up progress and cause expensive delays that flow on to other jobs.

“Labor and materials for any of these items can ‘suck up’ any, and often all, of your profit,” Smith noted. “Many of these things are not even dependent on the size of a job, but simply required to complete the job.”

In the case of AppliCad software, Smith said these items can be treated within the software as either a compulsory extra item, an accessory to a primary component, or as an optional item that the estimator is prompted for. Once set up, the process virtually eliminates losses from these issues on future jobs.

Use all the tools available

One of the first places you will want to look within the software is accessories to panels and flashing/trim. “The software will automatically calculate the correct quantity based on how they are fabricated and installed. This can get confusing, especially for manufactured mitred corners, or clips and brackets—as these items might be different for various combinations of trim or different roof geometry; for example fascia with gutter, fascia without gutter, or fascia merging with a rake/gable or simple fascia only along an eave,” said Smith, adding, “Defining these accessory items can be tedious, but you do this once and the benefits flow on with every job you complete.”

In addition to creating an accurate 3D model of your roof, you will have verifiable accuracy in the take-off of every clip, screw, tube of sealant, labor and additional materials.

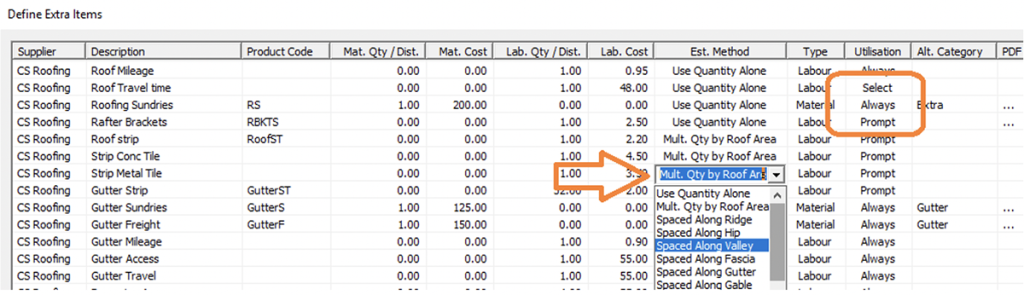

Define extras

The second part of a profit saving set up is using what AppliCad defines as Extras. Extras can be anything that goes into a job, labor or material, part of the roof, or simply part of the job.

They can be compulsory extra items or optional extra items that you are prompted to include, or already exist in a list of items within the software.

The sort of things that you might include as an Extra item range from various types of crane hire, dumpster rental, compliance paperwork, travel time/mileage, generators, site inspections, power poles or even leaf guard.

Some estimators include various types of extra items in their list as a ‘compulsory item’ with zero value. This assures that the item appears on the list and serves as a prompt when preparing quotations; the quantity adjusted for a particular project. “The software has a switch that allows you to turn off zero quantity items when the quotation is printed, thus ensuring that you never forget anything that might comprise the detailed and thorough client proposal,” Smith said.

Ongoing Review

Smith encourages software users to continually review your items list. “You should be constantly reviewing your jobs won and jobs lost and also review each job on completion. Take note of the things that ‘bit’ you and update the list,” he said.

It all adds to your bottom line.

“Do the best job you can for yourself and your customer by investing a bit of time in the systems that help you. It is a very good investment for the long term and means that everyone in your team gets the benefit of the combined experience of you and your field crews. You can count on a profitable job because you accounted for everything at the estimation/quoting stage.” RF