By Sharon Thatcher

The fourth industrial revolution (Industry 4.0) in the form of artificial intelligence (AI) has arrived in the roll-forming industry. What does it look like and how can your business benefit?

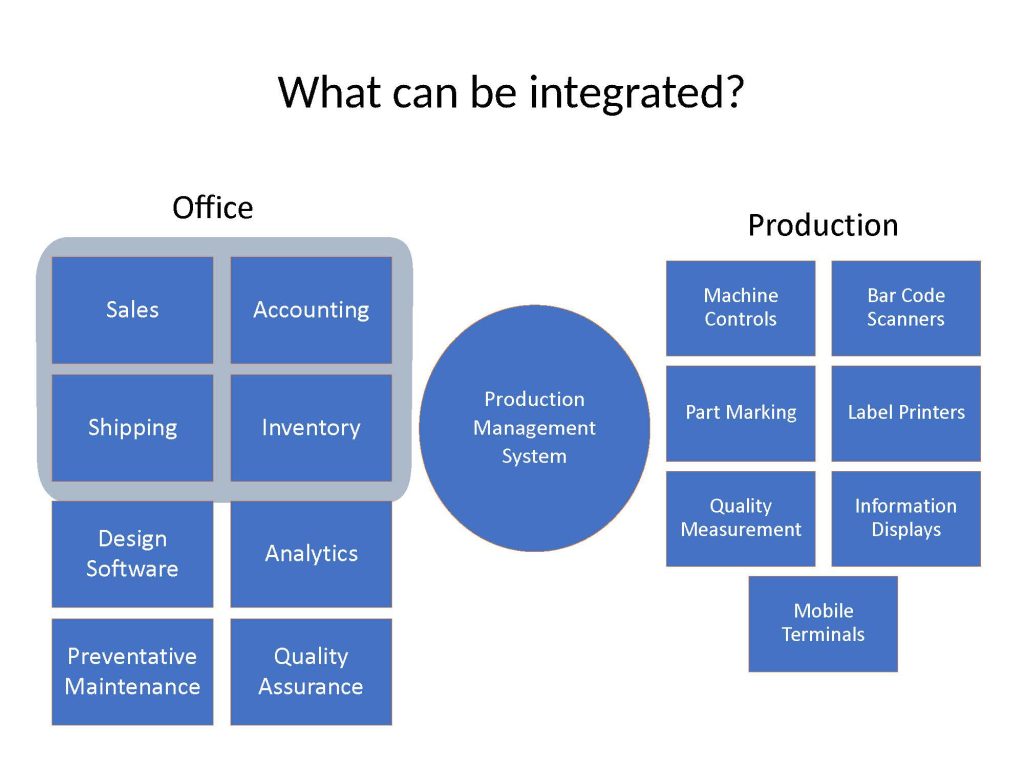

A simplistic explanation for what it is can be described as machine controls and related software that improves data collection and integration of all systems from shop to office. Huge advancements have been made in this arena, and many metal fabrication shops have already embraced it.

If you operate like many small- to mid-size shops, however, you have a hodgepodge of systems or wish to completely ignore Industry 4.0 automation entirely. While ignoring it may not be the best solution long term, Shawn Huffman, Sales Manager at BECK Automation, assures you that options for how much to embrace it can vary. “There’s not a one size fits all,” he said. “It’s all going to depend on your business needs, the size of your company; the ultimate decision is up to you.”

There are basically three areas of automation in the roll-forming world:

• The controller (the physical controls at the machine)

• Office software (to manage day-to-day business activities)

• Office-to-shop integration software (connecting the above) .

The Controller

Originally, roll-forming machines and folders came with very basic controllers, limited to allowing single batch programming. “The downside is that it doesn’t communicate with anything; the operator has to program [each job into the machine] one at a time,” Huffman described.

Many shops in the regional roll-forming world are still steadfastly dedicated to this basic, manual control. As National Sales Manager, Ryan King with CIDAN describes: “Trim parts are often still drawn on a napkin or piece of paper.” It is certainly still a workable arrangement, however, it can also result in longer lead times and a higher likelihood of mistakes.”

Regional shops catering to the local market for metal roofing and wall panel, and related metal building components became popular for the ability to deliver product quickly. Now the definition of ‘quick’ is changing. “Every industry around us is becoming like Amazon Prime,” King said. “If you can’t get it in two days on Amazon Prime—do I even want it now?”

Wayne Green, Eclipse Product Manager and Engineered Sales for AMS Controls, believes that the larger a company becomes, the need for accountability becomes greater. Staying manual through growth means quality will start to slide. “You can’t give everything the attention it needs,” he said. “There’s lots of things that fall into the cracks. The accountability at all levels needs to get higher… And the higher the accountability, the higher the profitability you typically have.”

For shops wanting to expand and compete in a broader market, modern controllers allow the operator to program in multiple orders with easy-to-navigate color touch screens. They are also designed to interface via Ethernet to the office, and that’s where automation truly shines. The physical controller can now network with robust software programs that can track product from input to output and even to delivery. Available in industry-specific systems called ERPs (enterprise resource planning) they can help you track the entire life of a single coil from the time it arrives at your shop to when the finished product is delivered to your customer. When used to its fullest extent, mistakes, waste, and angry customers are substantially minimized.

Software choices

The metal components industry has many integrated manufacturing software options to choose from. Here is a partial list of those commonly used in the metal building components and panel world:

• Production (machine to office systems): Connex, Eclipse, nuIT, QB-Elite, MetalShop, Pathfinder Edge

• Industry-Specific Design: Applicad, SmartBuild, StrucSoft, Vertex

• Industry-Specific ERPs: Adjutant, Paradigm, RealSTEEL, SteelPro

With some systems you can pick and choose features à la carte, helping to reduce cost.

What industry-dedicated integrated manufacturing can do

The most immediate advantage to all the above integrated manufacturing programs is the ability to capture useful data and to eliminate the need for double entry of orders.

In the traditional manual system, an order is received in the office and the information carried down to the shop where the operator keys the information into the machine controller. As Huffman explained, it not only requires extra time to do that but “there’s opportunities for errors and there’s downtime associated with that.”

Integrated manufacturing systems allow you to send multiple orders directly to the machine controller from the office, making the information available simultaneously in both places. The operator can still enter orders if needed, but larger businesses are taking that task away from operators so more time can be spent on actual production. As AMS Controls President Andy Allman noted, it takes time to key in entry, and “if that’s happening at the machine control on the floor, that means the machine is not running.”

Other important features of integrated manufacturing systems

Coil tracking and validation:

Each coil can be assigned and tagged with a unique code or number that can be tracked with a hand-held scanner. Immediately you can verify the gauge, width, and color. Does it match the material needed for that job?

It offers a look at where a coil was manufactured and how it is being used: what jobs it was used for, how much scrap was generated and the reasons for that scrap—was it bad coil or poor control over the run? If the latter, do you need to talk to your operator to change the way he’s running the machine, or do you need to call your vendor to tell them they’re sending you bad coil?

Good tracking leads to order validation, making sure you have the right materials for the job you are running. Running the wrong coil can be very expensive, as Wayne Green recalls from his former business experience. In his case, a color-blind employee, with an otherwise stellar work record, picked the wrong coil color for a job. “It was an order that had to get out the door quickly,” he said. The order ran in its entirety: a $10,000 mistake.

Such unintentional mistakes are common and could have been avoided with an integrated manufacturing system. Error warnings can be set up to coordinate with order information. When the coil on the machine doesn’t match the coil needed for the order, an error message pops up. Is this coil an approved substitute? Does it require a supervisor’s password to override the error and continue, or correct the error with new coil?

Green believes production management software integrated with machine controls not only benefits the business owner and customer, but also the employee. “It can take an employee with a handicap [in this case color blindness] and allow them to run at a high level.”

Production management software integrated with machine controls can also help you:

• track inventory (how much material is currently in inventory and what will be needed for upcoming jobs)

• maintain a proactive maintenance routine (listing all the things that need to be performed on this machine today and written or video how-to instructions)

• track employee production (When was the machine turned on and off, how much down time in between, and how was down time used?)

• track key performance indexes (What is the efficiency of the machine weekly, daily, hourly? If the machine is idle and orders are piling up, is it because the operator is busy with bundling and shipping tasks? If so, is it time to employ someone dedicated to bundling and shipping?)

• track shipping details (a barcode on a bundle tag can tell you this order needs to go on this truck, going on this route, and delivered by this date).

The Value of QuickBooks

Not mentioned in the above list of integrated manufacturing software is QuickBooks, and yet it is a very popular choice in the regional roll-forming world for accounting. “It’s a great program and a lot of customers use it. But it’s not going to cover everything. [For manufacturing] QuickBooks is entry level,” Shawn Huffman said. “There are things you’re going to need that aren’t in it.”

Before taking a job with AMS Controls, Wayne Green owned his own metal shop. He said of QuickBooks: “QuickBooks definitely gets you out of the gate; it does accounting extremely well, but it doesn’t do the manufacturing side of roll forming, the equipment operations … QuickBooks needs a lot of workarounds to make it effective.”

As your business grows, you should consider stepping up to more industry-specific software options.

Andon Boards

For more advanced shops, Andon boards on the shop floor allow employees to see real-time performance metrics and other helpful information relevant to their machine: what order is up next, when coil or maintenance changes are scheduled. Monitors need not be expensive: a new smart TV from your favorite box store serves the purpose. Allman said the information they provide is “like having a manager on site at the line at all points.”

Controlled from the office, production output can also be displayed. Green thinks younger generations of workers adapt particularly well to this type of feedback. “Sometimes this is the first time they’ve come from gaming and high school into the real world,” he noted. “They relate to data feedback particularly well… It’s a psychological effect that if you give an operator their stats, most people will want to do better.”

If integrated manufacturing is so great, why are many regional roll formers reluctant to embrace it?

Reluctance to change is the easy answer, but Ryan King offers another explanation. “It’s a blessing and a curse that everyone has been very busy; you don’t care if you’re losing 2% if your business is up 20%. When you’re slower is when you need to reassess and re-evaluate your operation. Right now, I’m busy, busy, busy; I just need to get this out the door.”

Shop owners also may not readily understand the benefit. “When you buy a machine, your ROI is very big and measurable,” King said. “You went from buying materials from someone else to making them in-house. When you do that, you’re going to see an actual, easily measured ROI. When it comes to software it’s more difficult to measure, but you will save time and material once implemented.”

He said one way to look at integrated manufacturing: “It’s like buying a new car vs. a used car with lots of miles on it. Both get you to the same place, but one is more efficient in how it does it.”

Some companies that are embracing it are doing so out of workforce concerns. Older workers are aging out and younger workers are hard to entice. King said one of CIDAN’s machine models “can now efficiently and accurately do the work of 3 or 4 people, and all [the operator] is doing is setting a stack of material on a table and then collecting the finished parts.”

He added: “We’re selling more machines like this because of labor shortages and people needing to be more efficient. No one is buying this machine to lay off five people. They’re buying this to take the people they do have and have them doing more and working less.”

Is integrated manufacturing software worth the extra expense?

The direct, financial benefits are readily apparent in terms of streamlining data entry and tracking inventory, but Andy Allman said some of its greatest benefits are less apparent in the data it collects. “Regardless of which system you use,” he said, “integrated manufacturing helps you manage your workforce, tracks where your bottlenecks are, and where you need to invest next.”

If used as designed, he went on to explain, “the information you collect can be gold … [companies are realizing] amazing financial results from just understanding what is happening in reality on these machines. It can really have a huge impact on how they train their operators, how they spend capital, what was their best investment … It’s a tool that offers information you can act on.”

Wayne Green said the financial payback is sooner than what you might think: “What I’ve typically seen is ROI on investment, just from order download, is less than 6 months for someone running orders 8 hours a day 5 days a week. That extra 45 minutes to an hour that we are giving them back pays for the integration within six months typically speaking.”

You won’t be able to ignore its impacts on the industry indefinitely. Said Ryan King: “If you want to grow and play with the medium and big boys you won’t have a choice eventually. I think [automation] eventually becomes as important as buying the machine. As an industry, we’re not quite there yet but I think in the next 5-10 years we’ll see a great percentage of people using software other than what’s just on the machine.” RF