Those who depend on roll formers for their livelihood expect a lot from their roll forming line. They want it to do more, be more versatile and they want it faster. It’s not always easy, but that’s the goal when a customer requests or demands improvements.

So far, the industry has been able to meet the demands of customers for their roofing and wall panel roll forming machines. The industry has introduced innovations to help improve productivity, reduce downtime and reduce labor input.

Quick Changes

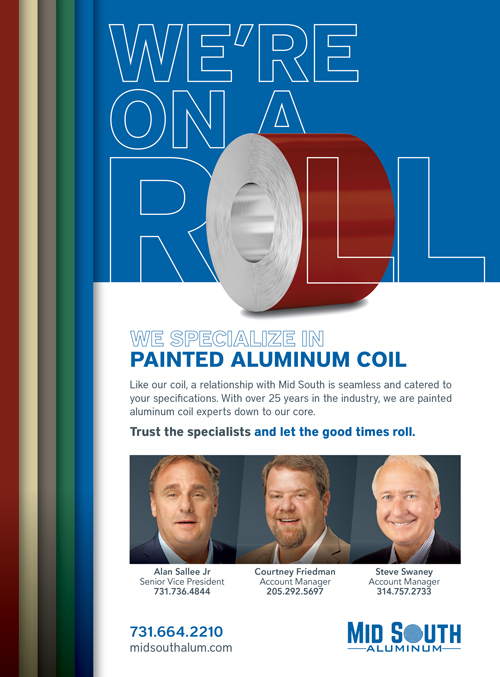

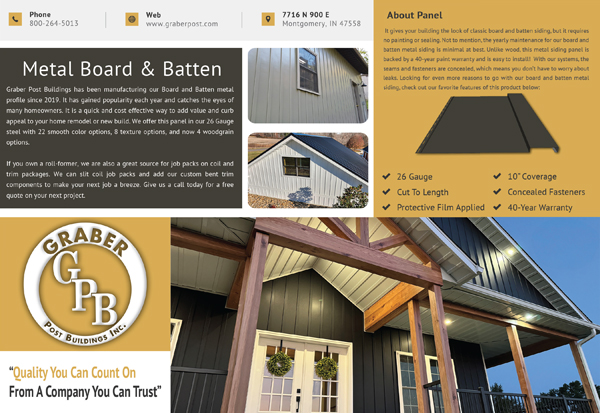

Machine versatility came about when customers wanted different features in their roofing and wall panels. It would be easy if every customer wanted the exact same panel, but they don’t. They want different profiles, different colors, different widths, different yield strengths and different lengths. It’s not practical to have four or five or six roll formers, but it’s become reasonable to expect one machine to offer enough options to satisfy a good percentage of the customers’ requirements.

Engaging different rolls has become a simple step in the roll forming process. If the requirement is for a standing seam roofing panel to have ribs, it takes a simple adjustment to the rollers to create ribs during the forming process. It’s a matter of turning it on or off. All of this info can be entered from a single control panel; a control panel that is connected to the entire line.

Running a different profile with the same machine can also be accomplished with double-high, side-by-side operations or rafted tooling. The use of rafted tooling has been a tremendous labor and machine time and scrap saving for the industry, as well as improving delivery time and improving your return on investment (ROI).

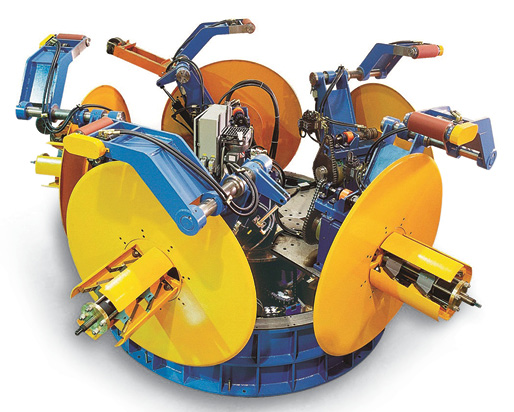

The industry has moved to the use of double-ended coil rolls, which has a large impact on productivity. The use of coil cars and turnstiles has added to these efficiency improvements. Forming a panel with a new color requires a different coil. Once a time-consuming process that could lead to a lot of material waste now is simplified by the use of multiple uncoilers. Uncoilers at the front end of the roll former can hold multiple coils to reduce changeover times.

To minimize material waste, shears have been incorporated into the front end of the machine.

Front-end shears cut the material before it goes through any part of the roll-forming process. If you can only shear at the end of the line, the material on the line becomes waste when you package what you need.

Organizing For The Job Site

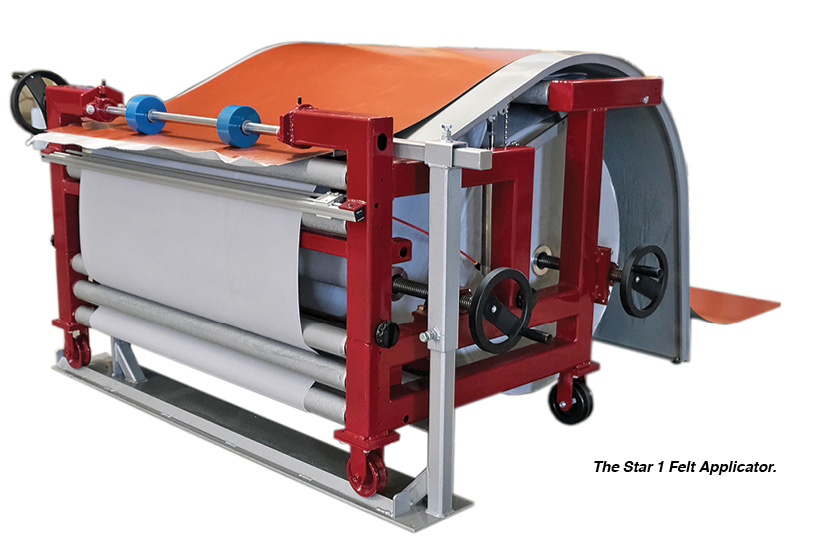

Time is money in the shop and time is money at the job site as well. Organizing the bundles of product, either roofing or wall panels, in a manner that allows the installer to unpack them in the order they are to be installed can be a logistical nightmare if you’re to do it manually. The process can be greatly simplified with an automated pick-and-place system.

When the panels arrive at the job site, they are bundled to suit the installer. The first panel off the stack is the first installed, the second panel off the stack is the second installed. It saves a lot of headaches at the job site.

The industry has developed automated panel stackers, which can create “pyramid piles,” which are safer to handle compared to the old bundles where all panels, regardless of length, flowed to one end, making the bundle un-stackable and dangerous for handling.

The various machines in a modern roll-forming line receive instructions by programming and can adjust almost on the fly.

Operators don’t need to input information. This saves time and assures accuracy and efficiency.

Recent technology has enabled machines to receive information “from the office,” or from someone other than the machine operator. Data can be programmed into the machine to produce several different parts during the course of a day, all with no downtime.

When a batch or run is completed, the machine is already programmed for the changeover to produce the next part. The machine has the capability to complete the changeover and commence production. Machines without this capability require a manual changeover of tooling, executed by the machine operator. This introduces the possibility of an error and certainly increases downtime and the time it takes to produce the same number of parts.

These machines also have the capability to provide data feedback to the office at any time during the day on what products have been produced, while monitoring the accuracy of parts produced. At the end of a work shift or a work day, information can be easily gathered to determine what was all produced, including a breakdown by number of each part.

If a “bad part” is produced, for whatever reason (usually a flaw in the material), those parts will be automatically diverted to a “bad part” pile. Without that capability, these parts would have to be discovered and removed manually.

Industry Leader; Unique Roll Formers

Samco Machinery designs each roll forming machine with a specific customer in mind. Each roll forming line is unique and can offer the most efficient innovations available, to save time and money … through improved machine efficiencies to greatly reduce downtime and reduce labor costs.

Jaswinder Bhatti has been with Samco Machinery for more than 30 years. He started on the shop floor and worked in every department all the way up to plant manager. He currently serves as Samco’s vice president of Applications Engineering. Bhatti also sits on the board of directors of the Canadian Tooling & Machining Association (CTMA).

Samco Machinery provides customers leading-edge designs and cost-effective solutions to satisfy any metal roll forming project need. Maintaining ISO 9001 certification, Samco manufactures roll forming machines, uncoilers, roll tooling, presses and material-handling solutions servicing a multitude of customers worldwide in varied industries. Visit www.samco-machinery.com or contact [email protected] for more information. RF

- Material Handling System (Photo Courtesy of Samco Machinery).

- Panel Stackers Pyramid Piles (Photo Courtesy of Samco Machinery).

- Five-head Uncoiler (Photo Courtesy of Samco Machinery).